Are you one of the 40% manufacturers who are not (yet) familiar with additive manufacturing?

Fluctuating supply chains, keeping an eye on costs, eA high degree of product variety and a high degree of customization are forcing companies to become more innovative. By using disruptive technologies such as additive manufacturing (AM), manufacturing companies are becoming more competitive in today's fast-moving market.

The possibilities of additive manufacturing, also known as industrial 3D printing, are generally not seen as a replacement for, but rather as a complementary manufacturing technology for companies.

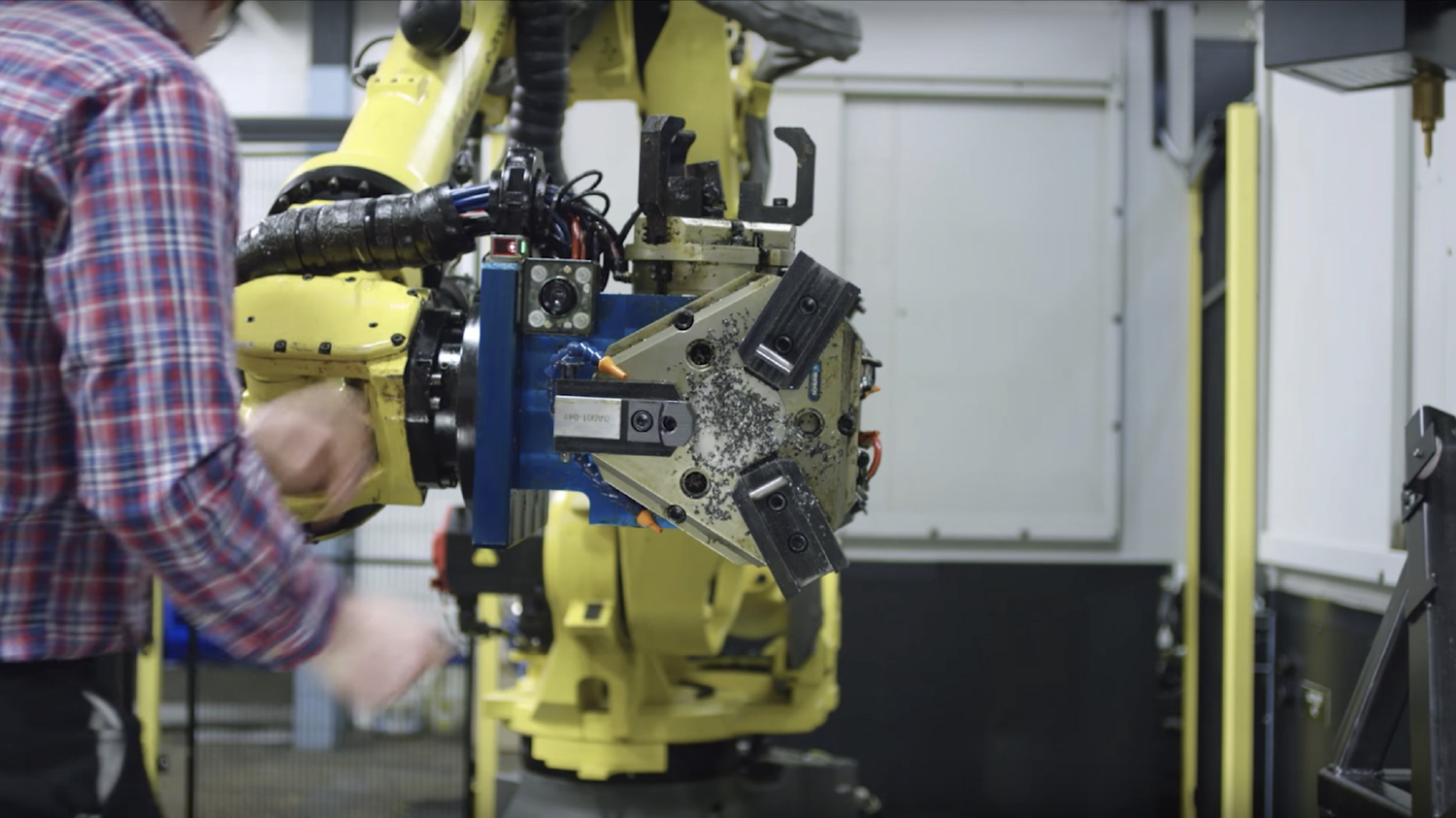

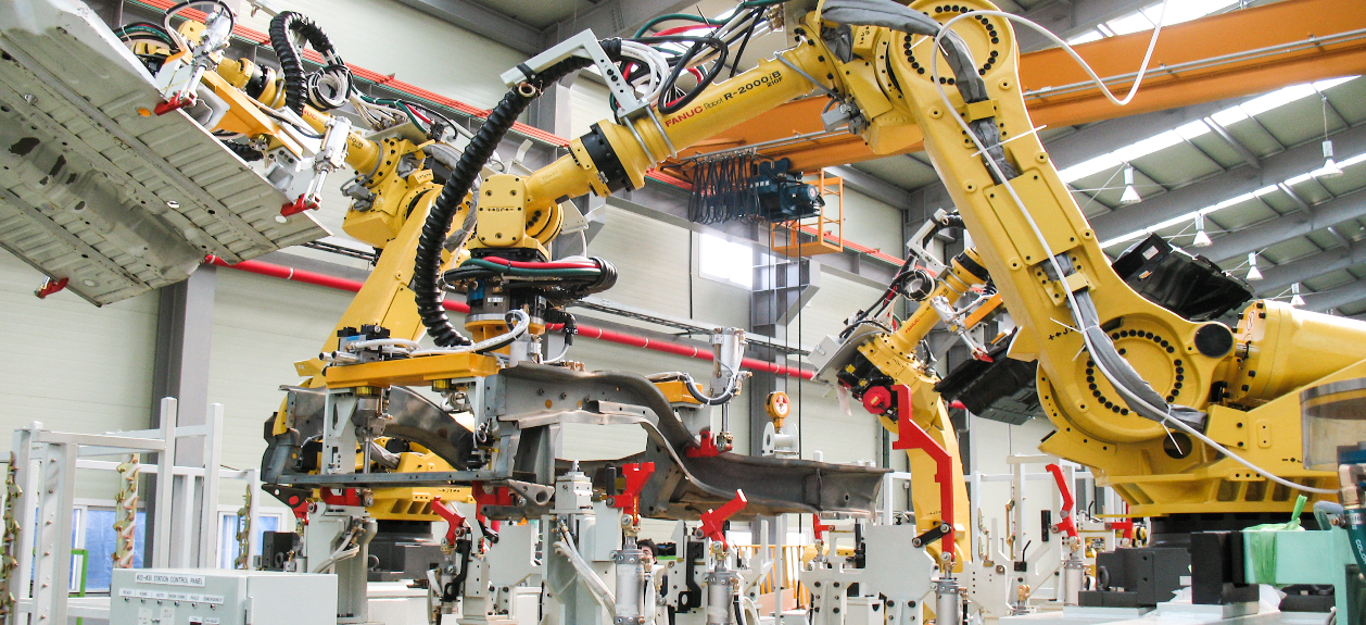

Conventional manufacturing technologies such as CNC machining have proven themselves over decades and will naturally continue to have their place in production halls in the future. The goal is to effectively leverage the advantages of both additive and conventional manufacturing technologies. each other to connect:

What is important for manufacturing companies?

Manufacturing companies must be able to rely on additive manufacturing in industrial environments. Therefore, a reliable and process-safe system with high repeatability is a prerequisite:

What are the benefits of integrating additive manufacturing systems into your company?

A technology that was once limited to prototyping is now being extended to tooling, small-batch production, and spare parts in industry, reducing manufacturers' manufacturing and inventory costs and drastically improving production efficiency. 3D printing in industry is more than just prototype production.

If you have questions about production optimization, industrial 3D printing can provide the answers. From initial visual samples and prototypes to ready-to-use machine spare parts. Regain availability, become independent of your supply chain, and become a driver of innovation for a secure future for your company.

If you have questions about production optimization, industrial 3D printing can provide the answers. From initial visual samples and prototypes to ready-to-use machine spare parts. Regain availability, become independent of your supply chain, and become a driver of innovation for a secure future for your company.

One step ahead of the competition

However, a McKinsey study reports that 40% of the industrial manufacturers surveyed are not familiar with additive manufacturing technology “beyond press coverage.”

Your manufacturing operations, which should represent a competitive advantage, are suffering from technology dissatisfaction. Don't wait until margins shrink and your technologies become obsolete. Get one step ahead of your competition and schedule a consultation for Markforged 3D printers today.

With capital investments from industry leaders like Microsoft, Siemens, and Volkswagen, we have gradually introduced the phases of integrating disruptive technology into large and leading organizations. We're here to share what we've learned in the field of 3D printing and demonstrate the possibilities for leveraging additive technology in your operations.

We support you all the way – from entry into additive manufacturing to the digital forge

Experience additive manufacturing technologies as a tool for achieving faster time to market, reduced manufacturing costs, and improved manufacturing and supply chain efficiency. Conduct an operational diagnostic to learn where 3D printing technology offers the greatest benefits for your operation.

Practical applications of our customers

Learn more about industrial 3D printing!

The economics of 3D printing

The cost-effectiveness of 3D printing has long been a major topic in mechanical engineering companies. If this is also the case for your company, this guide will help you decide on a Markforged 3D printer.

In this guide, we summarize the requirements you must consider when designing components to be manufactured using additive manufacturing.

Simply fill out the form on the right and you will receive the guide immediately.

Fill out our secure form to download the free guide directly.