Mobile 3D printers in action!

The British Army, the United States Army, and the Dutch military rely on Markforged 3D printers. This allows them to easily print necessary components such as fixtures, brackets, tools, and spare parts directly on-site within a very short time.

From the sketch, through the design, to the first 3D-printed prototype in just a few hours. All on-site at the application site, without long waiting or delivery times. Thanks to the option of inserting continuous fibers made of carbon, Kevlar, or fiberglass into the components, the components are guaranteed to be robust enough to withstand the demands of the environment.

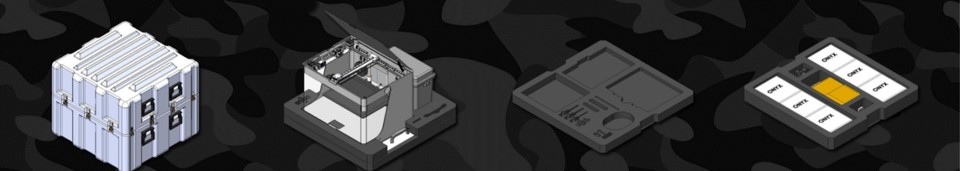

The Markforged X7 (FE) Field Edition

The robust housing of the Markforged X7 3D printer also serves as a base, allowing for working at an ideal height. It also provides storage space for spare parts and materials.

The included consumables, spare parts, and materials enable trouble-free use of the 3D printer.

Thanks to the ingenious concept, the use and first printing of a component is already possible after only 3 minutes possible!

Mark3D GmbH is your partner for the Markforged X7 (FE) Field Edition

Military operations often take place in very remote areas. Deliveries of spare parts, useful devices, or mounts often take weeks. At Markforged, we've developed a mission edition specifically for this:

The highlights:

US Navy field report

Stay one step ahead with durable, versatile parts on demand

A key U.S. Army training base offers realistic joint and combined-arms training to prepare U.S. Army soldiers and leaders for the battlefield. Here, soldiers are trained for upcoming missions, no matter where in the world they are. By using additive manufacturing technology, the Army is able to create readiness factors that reduce downtime.

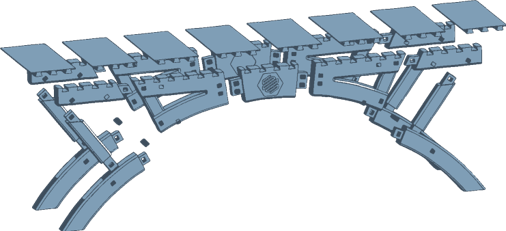

Night vision goggles

“3D printing gives us the opportunity to respond quickly and flexibly to changes.”

Markforged customer (USAF) 27th Special Operations Wing at Cannon Air Force Base recently released a video showcasing their Markforged industrial 3D printer and the applications they have developed with it.

Night vision goggles required various individual mounting parts that could be 3D printed quickly and cost-effectively.

Availability. Independence. Innovation.

Distributed manufacturing

Assembled in less than 10 minutes!

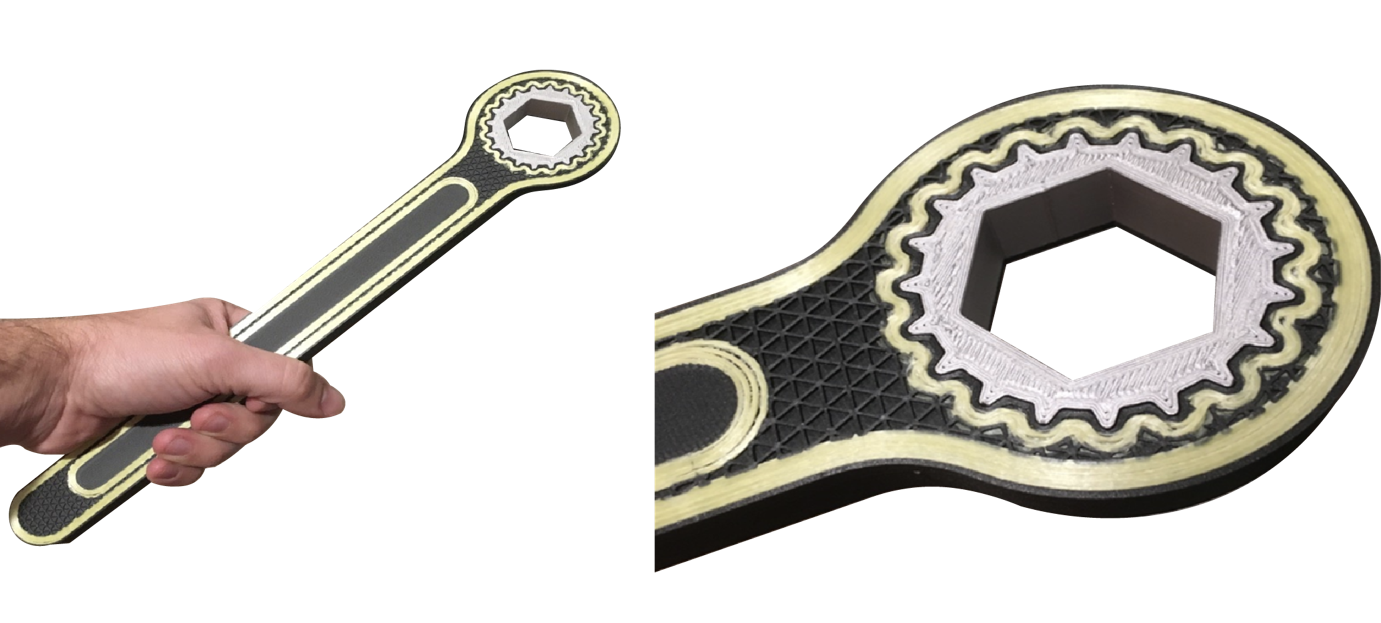

Individual tools

Kevlar-reinforced wrench handle with 1.2344 tool steel insert! Printed on the Markforged X7 and the Metal X system.

Secure manufacturing platform: The EIGER software

Markforged 3D printers control print jobs via EIGER software. Data can be imported from virtually all types of 3D CAD software. Markforged is committed to providing the most secure platform for additive manufacturing. We are the only 3D printing OEM with ISO 27001 certification and offer a platform that can operate offline, online, or within a secure intranet. With Markforged, you can leverage digital manufacturing without putting your business at risk.

More about Markforged Digital Forge and the Eiger Software can be found here

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

If you'd like a demo, have questions, or need a quote, please leave us a message here:

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

World-leading companies use Markforged 3D printers

To contact us, please fill out our secure form.