3D printing in plant engineering

In plant engineering, special customer requests often have to be implemented, which quickly become costly in development and production.

This is where additive manufacturing in plant engineering provides the perfect support.

The 3D printed components are used not only for display samples or functional prototypes but also as end products.

From prototype to series production at BMF GmbH

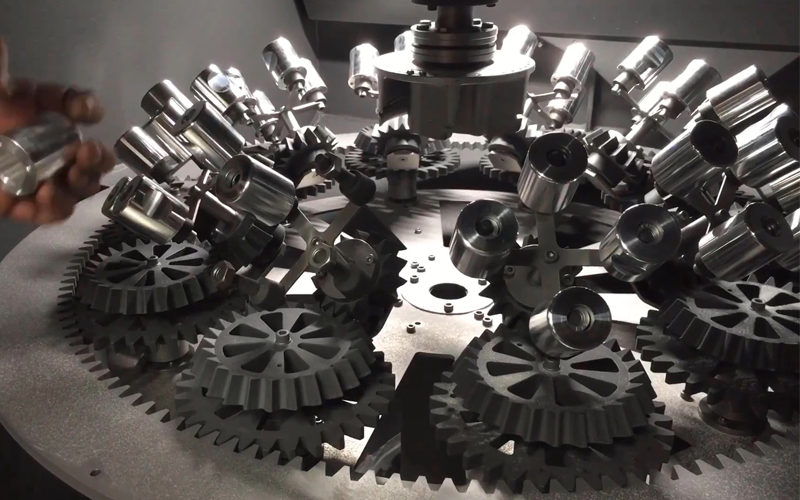

Due to the multifunctionality of the Smart Surface Control technology developed specifically by BMF GmbH, a multitude of different components are required, some of which require complex manufacturing. This previously required a long production lead time and complex warehousing.

Customer requests, such as special fixtures, could only be implemented to a limited extent. The goal was to replace as many machine components as possible with additively manufactured components, minimize inventory, and streamline or shorten production processes.

Request a DEMO component now!

See for yourself how strong the components are.

3D printing has become indispensable

Kessler Plastics GmbH has set itself the goal of offering its customers better and faster access to prototypes without having to produce new, costly injection molds. Development cycles should be accelerated or even reduced. Furthermore, the demands on prototypes are particularly high – the goal was to produce dimensionally accurate prototypes of top-quality, comparable properties to the subsequent injection-molded material, making the feasibility and cost-effectiveness of future series production perfectly predictable.

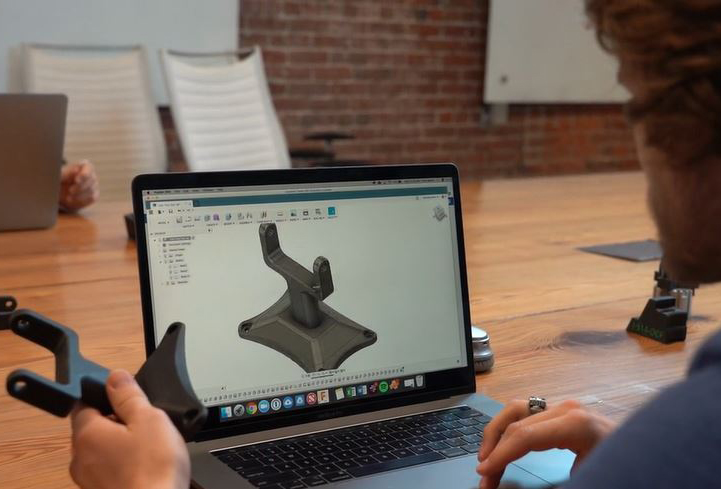

Get to know EIGER now!

The Markforged EIGER software is powerful and very easy to use. Your parts can be quickly optimized with the right settings and fiber orientations to optimally design your part for your application.

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

If you'd like a demo, have questions, or need a quote, please leave us a message here:

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396-00

E-mail: markforged@mark3d.de

World-leading companies use Markforged 3D printers

To contact us, please fill out our secure form.