3D printing technologies

[3 minutes reading time]

What 3D printing technologies are there?

There are many different technologies, each associated with a different material type. Here you will find an explanation of the most important technologies.

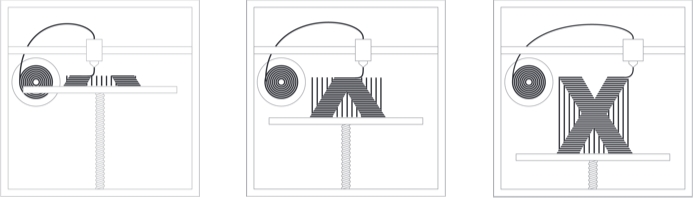

Extrusion

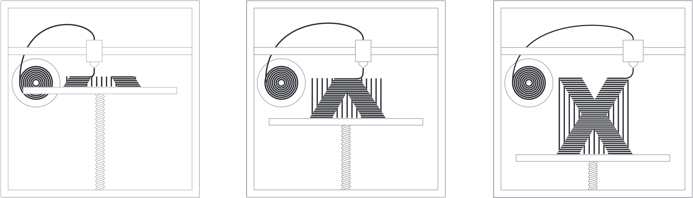

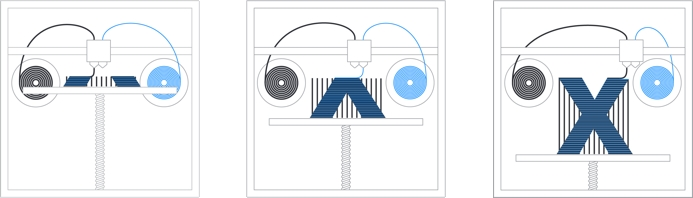

FFF (melt filament production)

Thermoplastic material is heated and extruded, then a cross-section of the model is applied. This process is repeated layer by layer until complete.

CFF (continuous filament production)

Printers use a second nozzle to infuse continuous filaments of composite fibers into FFF-extruded thermoplastics during printing. This allows for strong, rigid parts to be achieved through reinforced fibers.

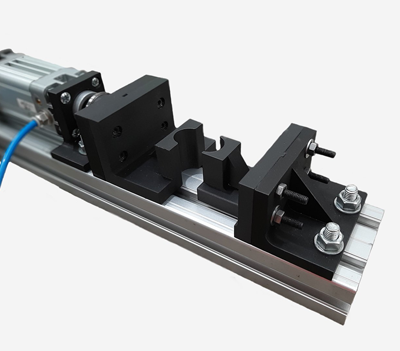

ADAM (Atomic Diffusion Additive Manufacturing)

Metal powder is bonded with plastic and applied layer by layer. Once the print is complete, the part is washed to melt the binder and sintered in a furnace to form an isotropic metal part.

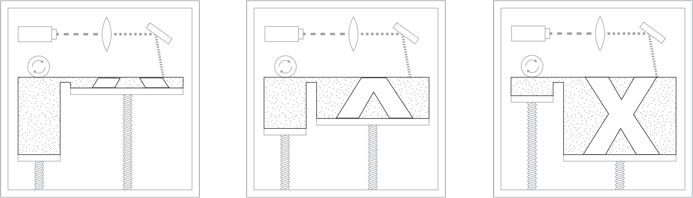

Laser fusion

SLS (Selective Laser Sintering)

A roller applies powder for each new layer, while a laser bonds the material together. The chamber is moved down for the next layer of powder. This process is repeated until the part is fully printed.

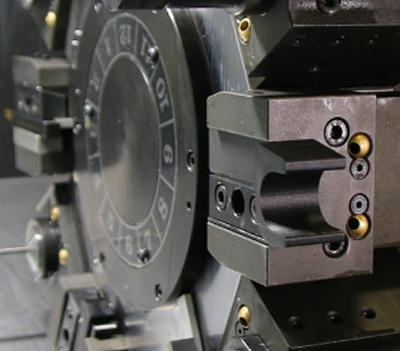

SLS / DMLS (Selective Laser Melting / Direct Metal Laser Sintering)

Powder is precisely melted to build a metal part. Layers of metal powder are distributed and then melted with a laser to fuse the powder particles together.

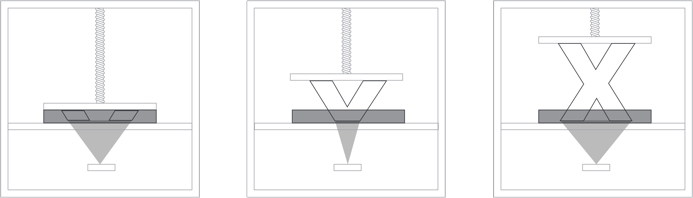

Light curing

DLP (Direct Light Processing)

Photopolymers are cured with light projected from below the resin tank. The photopolymers are in liquid form and rise layer by layer from the resin tank.

SLA (stereolithography)

Photopolymers are selectively cured with a UV laser. The resin is cured layer by layer until it is completely cured.

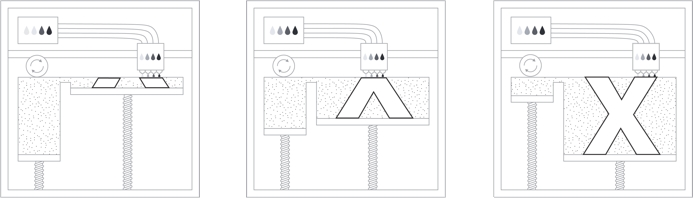

Force liability

Binder nozzles

Powder is applied and a bonding agent is applied to bond the particles together. No support structures are required, meaning the build plate can accommodate multiple parts.

Learn more about the applications with the desktop series!

How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed some information sources that will help you get the answers you need.

If you'd like a demo, have questions, or need a quote, please leave us a message here:

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

To contact us, please fill out our secure form.