More than just prototyping

In production, you rely on individual equipment and production aids such as fixtures to ensure quality, efficiency and occupational safety.

Markforged's industrial 3D printers enable additive manufacturing of mechanically and thermally resilient components. Markforged is a digital platform that allows you to make components available on-demand, anytime, anywhere in the world.

3D printing streamlines and improves the production of these tools, leading to higher productivity and better ergonomics. The technology is far more than just rapid prototyping. You can easily produce mechanically resilient spare parts, equipment, or functional prototypes overnight.

Counselor:

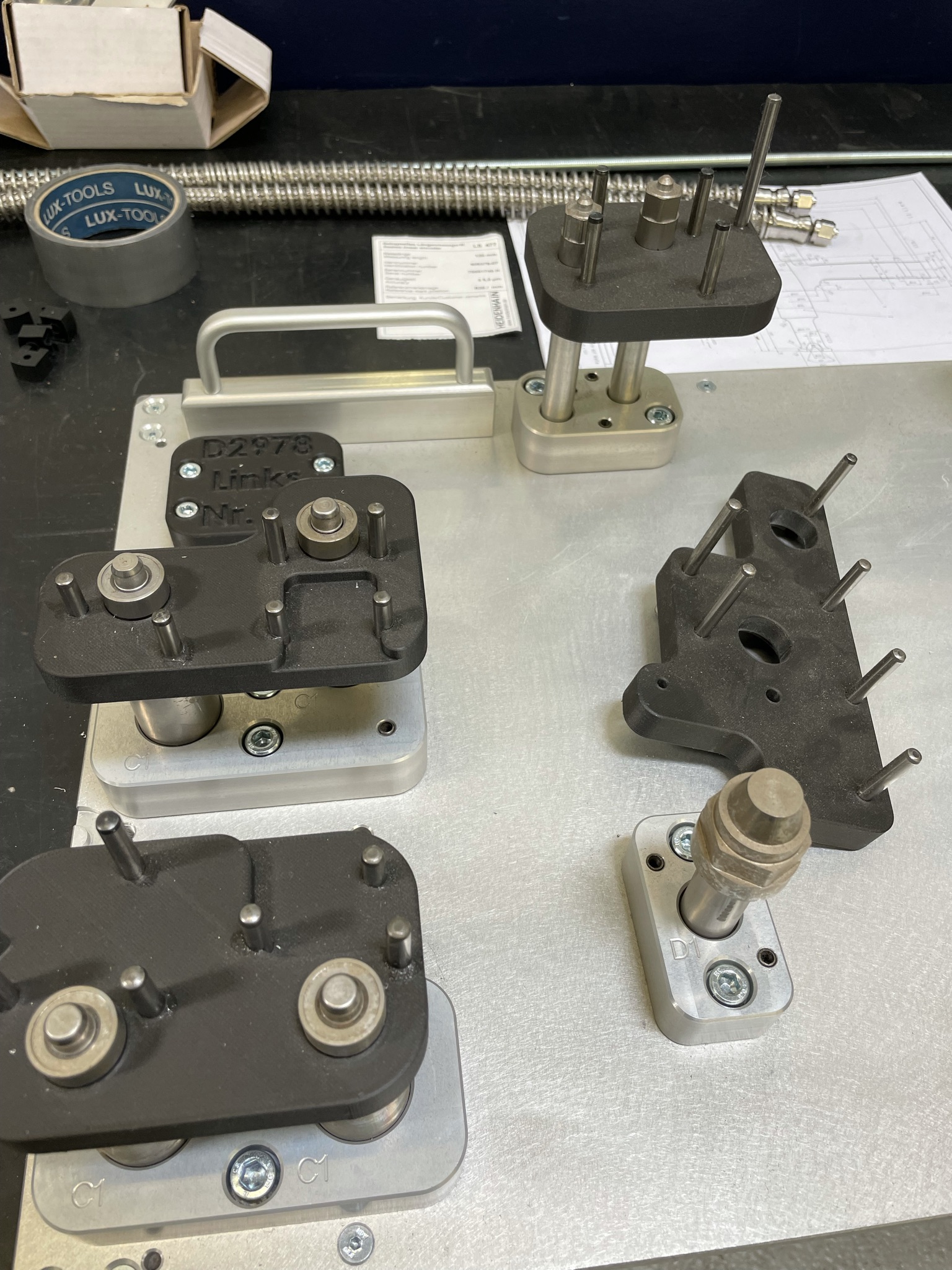

3D printed fixtures and brackets

Industrial 3D printers produce high-strength parts that are robust enough to withstand use in production environments. Equipment such as tools, fixtures, clamping elements, and soft jaws.

Learn, through practical applications, how 3D printed tools and fixtures shorten lead times, reduce material costs, and increase machine uptime.

Advantages of 3D printed fixtures & fixtures

Toolless production tools provide manufacturers with real added value.

Simplify tool manufacturing

3D printed fixtures and fixtures are a simple and cost-effective alternative for manufacturing complex tools.

Learn how 3D printing lowers the threshold for justifying a new tool by simplifying the process, reducing costs, and shortening lead time. This allows you to address potentially unmet needs throughout the production process.

Performance advantages

Industrial 3D printing and materials enable the production of equipment such as fixtures and fixtures, which bring many performance advantages to manufacturing.

Reduce costs

3D printing increases return on investment by reducing the cost of jigs and fixtures. Companies typically achieve savings of 70 to 90 percent compared to outsourcing fixtures that are machined or manufactured.

Printing of resources

Beyond fixtures, manufacturing tools that serve as operating resources expand the possibilities. They range from organizational bins and tool holders for 5S (a workplace organization method) to templates, guides, and gauges.

They include sophisticated robot grippers and rudimentary holders, containers and sorting machines for handling and transport.

Better design, better performance

3D printing also optimizes the performance of tools. Historically, fixture designs were rarely improved beyond what was sufficient to perform the task. Due to the cost and effort of redesigning and rebuilding, poorly performing tools were often reworked.

Print tools on demand

Print tools only when you need them. This reduces the cost and space required (warehousing costs) for managing and tracking inventory, as well as the cost of finding a fixture when it's needed. For tools used sporadically, these costs can be significant.

Industrial 3D printing as a manufacturing solution for your fixtures and fixtures

Support lean manufacturing strategies by 3D printing production tools on demand. Custom tools created directly from CAD can be ready for use the same day.

Reduce the time and cost of creating traditional tools and improve performance and accuracy. Print complex fixtures that would be impossible with conventional machining and manufacturing.

Practical report:

The additively manufactured components run like a common thread through the entire operation.

Almost every component is unique – due to the high level of customization, MMB designers face new challenges every day.

Until now, these components were manufactured using conventional methods (machining, casting, welding, etc.). However, low volumes, long lead times, complex geometries, and high costs limited this process.

The aim was to produce these individual components and small series more cost-effectively and to achieve significantly greater flexibility in design.

Practical report:

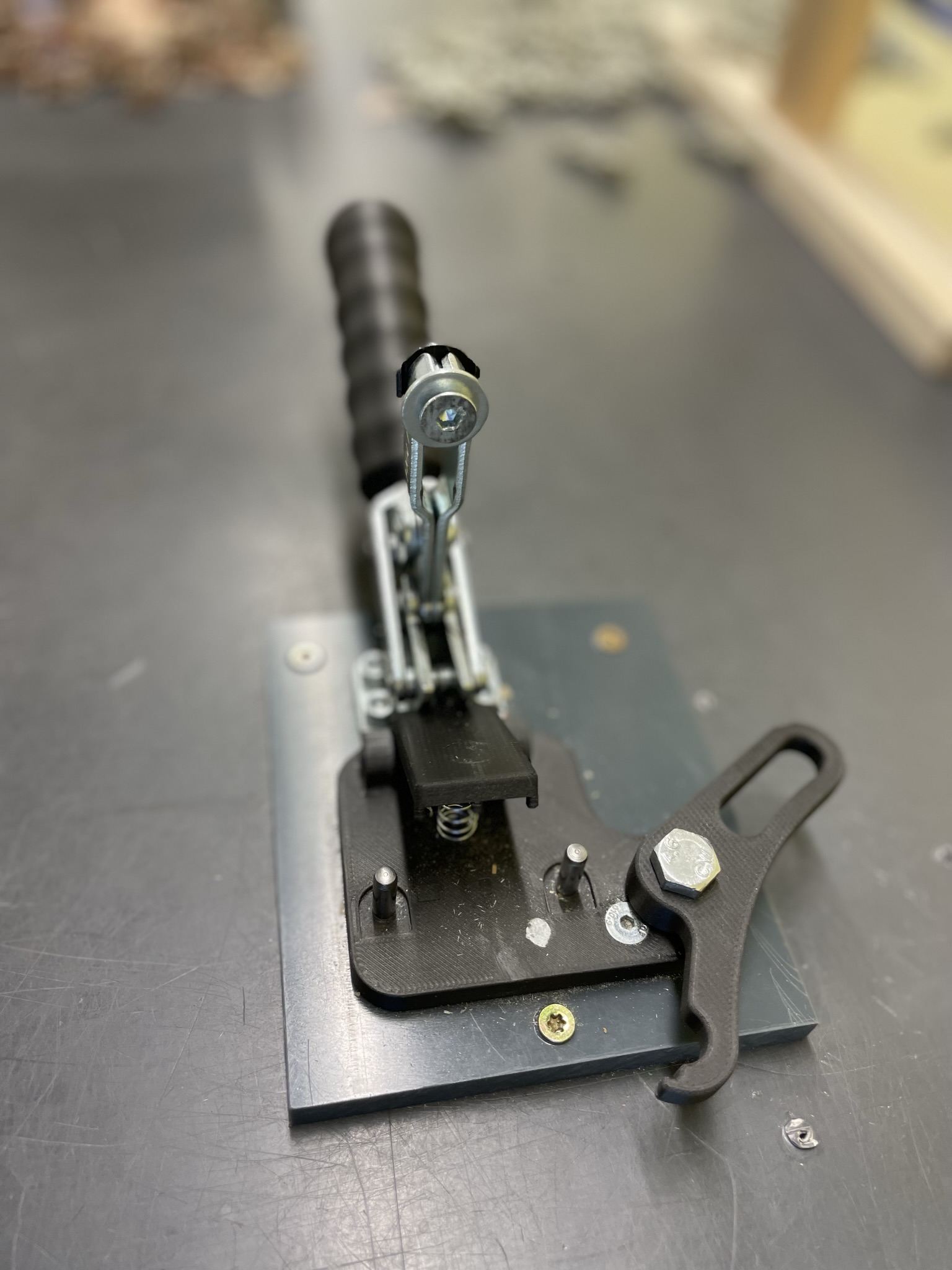

Drilling around corners is possible – with industrial 3D printing

After some consideration, this fixture was optimized using additive manufacturing with a Markforged 3D printer. The fixture was reinforced with continuous carbon fiber. A zero-point clamping system was also installed and channels were integrated inside the fixture. Now, forming gas can be directed wherever it's needed – with just one gas connection!

“Over 1000€ are saved per device!” – Raphael Willgenss, Operations Manager, Primetall GmbH

Practical report:

3D printed devices and brackets at Lebenshilfe Leer

The industrial partners usually supply the equipment and tools needed to process an order.

"However, these are often very expensive, as well as large and unwieldy. In addition, we only get a few of these fixtures. This means that only a small number of personnel can work on a single order. I can design my own fixtures much more effectively. The number doesn't matter either." The costs are also borne by the clients.

At Lebenshilfe Leer, Arnold Koens impressively demonstrates the importance of customized devices. In addition to the obvious savings in costs, time, and storage space, these devices enable many people with disabilities to work more comfortably.

Important mechanical and thermal properties of 3D printing materials

Functional requirement | Description | Short fiber-filled polymer | Continuous fiber reinforcement |

|---|---|---|---|

Stiffness | The extent to which a material deforms under load | Short fibers increase stiffness by 1.5 to 3 times compared to conventional polymers. | Continuous fibers increase stiffness by 20 times compared to conventional polymers. |

Strength | Maximum load the material can withstand before it gives way | The addition of short fibers slightly improves the tensile and flexural strength of the materials. | In addition, continuous fibers increase strength by up to ten times. |

Durability, shock resistance | The ability of a material to resist breaking and absorb energy under shock loads | Nylon is known for its durability and resistance to impact. The addition of short fibers further improves wear resistance. | Continuous fibers increase the resistance of parts, so that they deform much later. |

Durability, wear and tear | The ability of a material to resist the gradual removal or deformation of surface material by friction | Short fibers increase the abrasion resistance of the polymers, so they last longer in abrasive environments. | The fiber is only exposed when the outer surface of a piece is worn through - in extreme cases, it can even provide abrasion resistance when exposed. |

accuracy | How close a part is to the toleranced dimensions - both immediately after printing and after some time in use | Short fibers improve the volume drag coefficient of materials, thereby improving printing accuracy and reducing printing errors. | CFR does not affect initial part accuracy, but prevents dimensional creep over time, which is common in plastics. |

Heat resistance | The reaction of a material to elevated temperatures in use | Short fibers help stabilize the material at elevated temperatures and thus reduce warpage. | High-strength high-temperature fibers (HSHT) and other long fibers resist heat much better than matrix polymers, so HDT can rise to 145 °C. |

Resistance to Chemicals | Like a material reacts when it aggressive chemicals exposed to the manufacturing environment are available | Fiber-filled polymers on Nylon base are against the mostly in manufacturing used solutions and Lubricant resistant. | CFR has only a limited Effect, since the fibers in the Rule no chemicals are exposed to. |

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

If you'd like a demo, have questions, or need a quote, please leave us a message here:

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396-00

E-mail: markforged@mark3d.de

World-leading companies use Markforged 3D printers

To contact us, please fill out our secure form.