Additively manufactured equipment at CORAM TOOLS GMBH

In 1997, production of B-Cut saw blades for oscillating multi-function machines began under the name maRoc GmbH.

Until the company's rebranding at the end of 2011, E-Cut saw blades were produced there exclusively for one machine manufacturer. Since then, CORAM TOOLS GmbH has been operating under its current brand name.

Here you can find the recording of the webinar with our customer CORAM TOOLS GmbH:

Challenge

Diverse Variants on a Few Production Lines

Behind the CORAM TOOLS GMBH brand is inventor and managing director Marco Steiger.

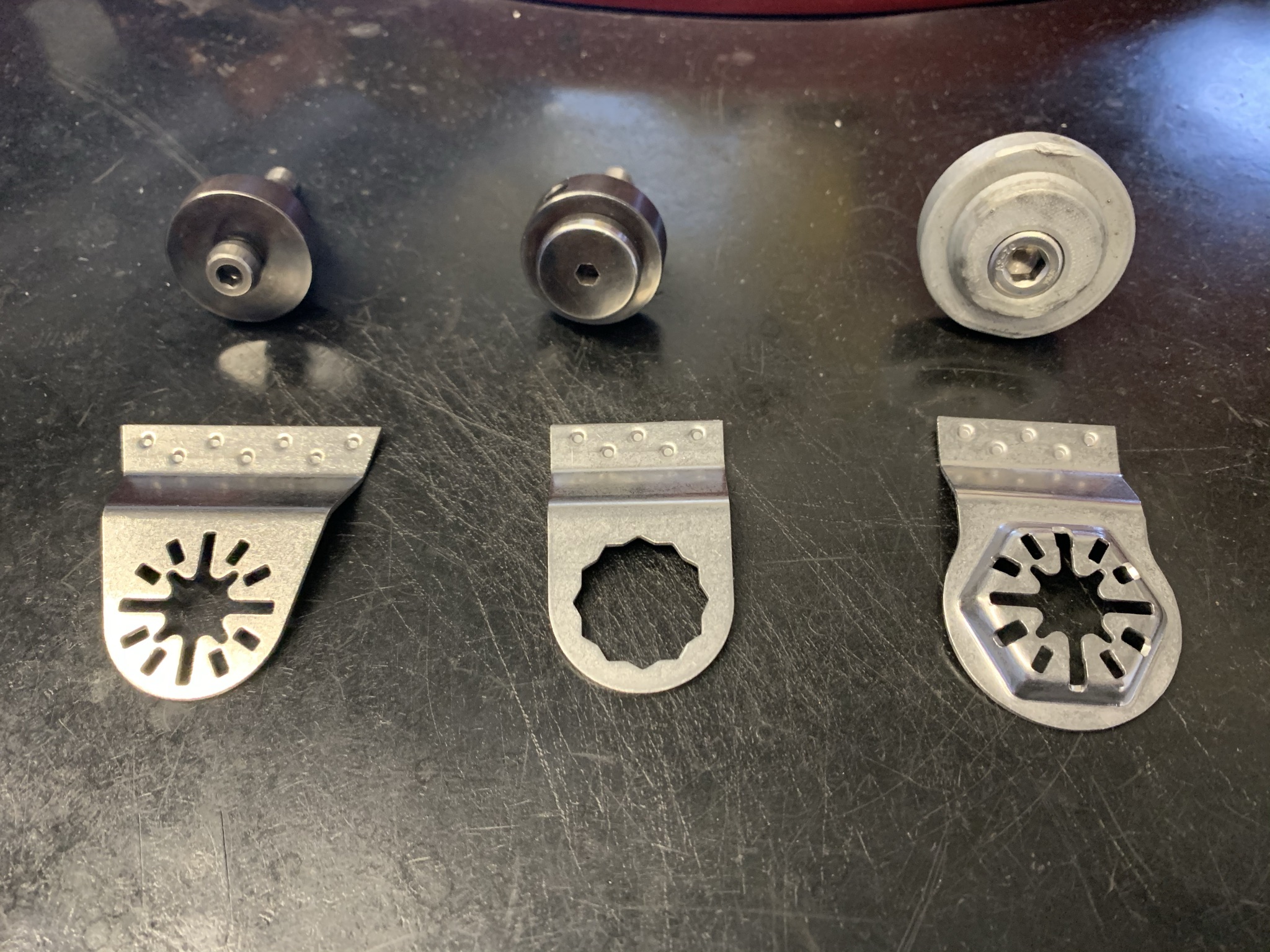

The oscillating saw blades allow for very thin, delicate cuts, for example, for window frames or doors. The tools have different shanks, which vary depending on the machine manufacturer, as well as different hardness levels (I, B, H) and application areas (wood, metal, PVC, or combinations). CORAM TOOLS thus manufactures 66 different saw blades. The challenge lies in making production as productive as possible despite this high degree of variety.

Request a DEMO component now!

See for yourself how strong the components are.

Solution

Fast Changeover During Changeover

Not all variants can run simultaneously on a production line, which is why the line has to be retooled frequently. How can this be simplified?

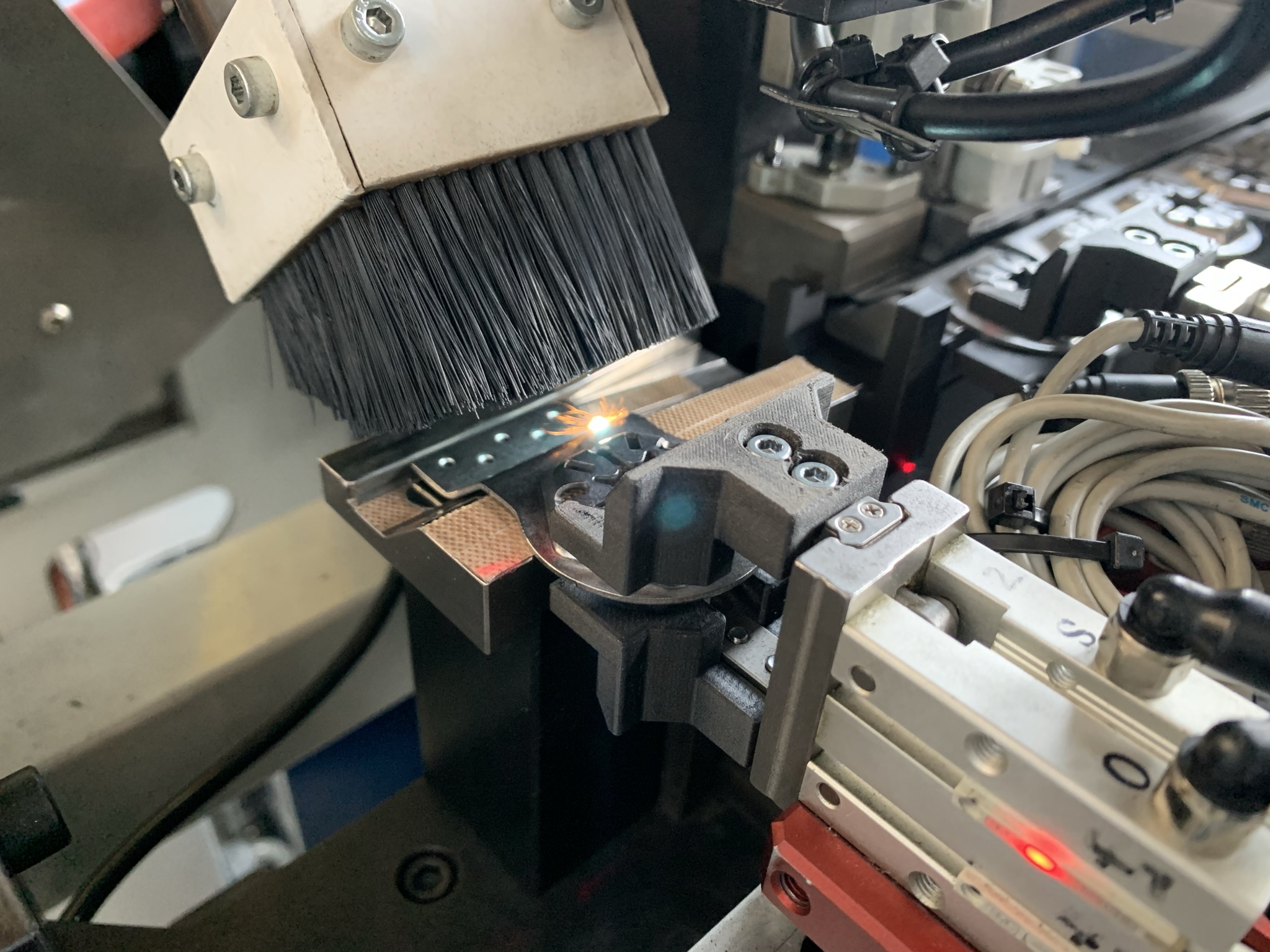

CORAM TOOLS made its first attempt at high-strength, fiber-reinforced 3D-printed parts with a gripper. This implementation made it possible to quickly produce customized and lightweight grippers.

Walking through the production area at CORAM TOOLS, it's noticeable that not just one part is manufactured using a 3D printer, but various small aids are used throughout. Even the simplest things were implemented; from collection containers to mounting brackets, production equipment and production lines were optimized, resulting in increased speed and reduced downtime.

The example on the left shows the laser marking process. For this, the workpieces are held with optimally designed 3D-printed grippers during the marking process. Heat is generated wherever a laser is used. The Onyx grippers have a heat resistance of 145°C – and even significantly higher under short-term stress.

All saw blades are labeled, sometimes even individually with the customer's logo. Incorrectly labeled parts aren't simply thrown away, but are immersed in a bath of liquid paint stripper. The holder for this is printed with Onyx. Despite the highly aggressive agent, Onyx easily withstands the challenges!

The future

Intelligent Tools

Originally, rejects from the machine were thrown into a box on the floor. Sometimes more, sometimes less successfully. But Marco Steiger had a better idea: He designed a collection container that could be mounted directly on the machine. To prevent it from breaking and the parts from falling out again, he reinforced the 3D-printed containers with continuous fiber. This way, everything stays where it belongs.

The collection containers were painted red for better visibility.

So far, the subsequent process is still analog: Each rejected part has a routing slip containing all its data. A possible next step would be to integrate an RFID chip into the containers so that the entire process can be digitally recorded and categorized.

There are many more examples of how CORAM TOOLS uses the 3D printer. When there is free capacity on the Mark Two, CORAM TOOLS also offers printing services.

3D printing is being used successfully in a wide variety of production halls. Additive manufacturing is not a future technology.

The future is now!

At a glance

CORAM TOOLS GMBH

Märwilerstrasse 43b

CH-9556 Affeltrangen

Telefon +41 52 544 22 22

E-Mail info@coram-tools.com

Internet www.coram-tools.com

Learn more about the applications with the MarkTwo!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.