Focus on customers

A new product launch can achieve so much more

at the Corin Group

Since its founding, Corin has been a pioneer in orthopedic innovation, enabling people worldwide to return to a faster, more positive, and safer quality of life. As a dynamically growing, global company, Corin is revolutionizing orthopedics with its innovative approach.

Its unique range of clinically proven solutions for the hip, knee, ankle, and shoulder, and its world-leading technologies, enable patients, surgeons, and healthcare providers to work together more closely than ever before.

13 Questions for Corin Group

Seamus Harrison from Mark3D UK spoke with Matt Smith, New Technologies and Process Engineer at Corin Group, about integrating 3D printing into their operations.

Jump to the question that interests you:

v

Why did you first look into additive manufacturing?

What was your first use case for the printers?

Why did you ultimately choose Markforged?

How did you justify the initial printer purchase?

What was your first print on the printer?

What was the learning curve like?

How has additive manufacturing made you think differently?

What has been your favorite application?

What materials do you print with?

How many printers do you have?

Describe your relationship with Mark3D.

What is the next step for Corin Group?

Read all about the user report

Project goals

The human body comes in a wide variety of shapes and sizes. For companies specializing in implant manufacturing, simplifying the process for handling variations is crucial.

Being involved in implementing new technologies and creating new processes simultaneously is an exciting challenge for any engineer. Just ask Matt Smith of the Corin Group, whose additive manufacturing program is well underway. Matt began his project in early 2020 with a printer justification based on several new product launches. Matt and his team set out to introduce a new stem and femur to their product line and explored what new technologies were available to help them do so in a timely manner. Each time a new product is launched, a large number of related fixtures are included. Being able to manufacture these in-house was a clear advantage and offered significant cost savings, making it the obvious starting point.

... “We decided we needed to explore additive manufacturing to be more flexible when launching new products. We were convinced there were many areas where we would benefit. But as we progressed with the project and more colleagues got involved, we began to realize its enormous potential!” says Matt. Just as the project was getting underway, the world was hit by the Covid-19 pandemic, and almost overnight, facilities, including many of Corin Group’s suppliers, were shut down.

Matt and the team faced the almost impossible task of ensuring their new project was delivered on time, while operating without raw materials, contract manufacturing, and with limited internal resources. At every stage of the production process, a shaft, whether forged or cast, undergoes operations such as machining, polishing, or laser marking, as well as rigorous final inspection with multiple checks. Without the ability to have a finished component for testing at each step, completing the project would be impossible.

At each stage of the production process, operations such as machining, polishing, or laser marking are performed on a shaft that is forged or cast, and a rigorous final inspection with multiple checks is carried out. Without the ability to have a finished component for testing at each step, it would be impossible to complete the project.

The engineering team began to consider this problem and collectively agreed on an approach that allowed them to continue working on several key elements of the project without ever seeing a physical metal component. Additive manufacturing provided the team with tools they had never had before.

"We simply printed replica finished parts, raw material forgings, and castings in Onyx and started the entire design process from there."

The solution

“We were initially approached by the inspection team, who asked us to print 48 variations of a ‘machined’ stem component. After this success, word spread quickly, and we were able to use printed parts for many steps in the process. So, we printed a full-size femur from the CAD model of the casting using Onyx and used it to run an initial test machining program to test the toolpaths developed in our CAM software. This part could then be passed on to the next person in the process for their design, and so on, until we were finished. Although we knew the feed rates and speeds would vary, the machining on the Onyx worked well, giving us good stability and part geometry on which to base the remaining processes.”

“My colleague started laser marking the onyx parts with great success. Another colleague designed the jig and engineered a way to capture all the different shaft sizes. This reduced the number of jigs needed, and we were able to write all the programs! Matt and the team had compressed the entire design process by working on it simultaneously. When the raw metal finally arrived, many of the inspection and laser marking programs were ready to go from day one.”

At a glance

Request a DEMO component now!

See for yourself how strong the continuous fibers are.

“When we began our additive journey, we had a clearly defined project, but due to circumstances beyond our control, we had to think outside the box to solve a supply chain problem, and 3D printers played a major role in this.”

– Matt Smith, New Technologies and Process Engineering Engineer, Corin Group

Machining

“The machining programs for the CNC machines were created and tested on life-size plastic models.”

Testing the toolpaths for 24 programs is a time-consuming activity and also means that other steps in the process cannot begin until they are approved.

The machining programs were written and tested in the background, using solid onyx parts instead of castings. “Using Onyx was great,” says Matt. “It gave us confidence that the toolpaths were correct, and since the parts are made of plastic, if we had done something wrong, we wouldn't have damaged the tool or the machine—the plastic parts would have given way first.”

The design and creation of robust machining fixtures using carbon or Kevlar also became much faster and easier for Corin Group. Sometimes the changes were simple, such as the clearance for a tool, and sometimes they were a little more complicated, such as the geometry of the point where the part is fixed.

Before the 3D printers were on site, Corin Group had to machine the clamping fixtures on its own production machines or send them to a subcontractor, where changes were not easy and costs were high. “Our development of the clamping fixtures on the printers was much, much faster, and we even identified applications where we can continue to use Onyx printing as a production fixture,” says Matt.

Laser marking

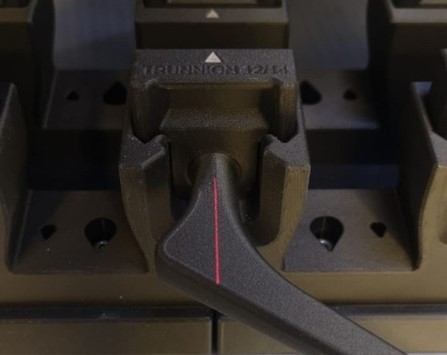

One team member developed an interchangeable fastening system so that we could use it for any shaft size.

Keeping 48 variants of a shaft for laser marking is problematic, especially when you are simultaneously learning how to use a new laser marking machine.

“In a strange way, using a new laser marking machine was an advantage,” says Matt. “Since we had this new machine that could hold multiple parts for marking, we looked at it from a new perspective. The old method of using one clamping device per part was simply unacceptable, so we had to develop a completely different approach.”

Corin Group decided to manufacture a single base unit and developed a range of interchangeable holders. A member of the design team worked with Matt on the project, and both sought advice and input from the machine operator. This collaboration would simply not have been possible if the work had been outsourced.

It is now possible to load a tray with 15 parts and laser mark them in one go, whereas previously we had to do this individually and would have needed 48 different fixtures. Our new fixture system means we can also mix and match part sizes. Changing a fixture is so easy that assembly and setup can be completed in a matter of minutes. The fixtures have been so successful that they plan to roll out the multi-part fixtures to the rest of the Corin Group's product range.

Inspection

“All of our inspection programs were written before we even saw a finished metal part.”

As we operate in the orthopedic healthcare sector, traceability must be guaranteed, meaning that “inspection” covers a wide range of things for Corin Group. There is the initial inspection of cast or forged components, the intermediate inspection of machined and polished surfaces, and, of course, the final inspection.

"We started with a simple ‘gauge’ for each shaft size, and we were very happy with how the printers met the tolerances we had to work with. The ability to simply slide a part into an Onyx fixture printed with default settings is a real advantage. Before 3D printing was implemented at Corin Group, we had to have these machined externally, which was very expensive and time-consuming. After we completed the design of the first part, we were so happy that we could simply modify the CAD model and print with confidence that it would meet the specification. Corin Group took the same approach to CMM and non-contact measurement programs that they had used when developing their CNC programs, working in parallel with the machining team. By printing the finished plastic part and handing it over to the inspection team, the automated routines required to operate their CMM machines could be created long before they saw a metal product.

“The plastic parts were stable enough to allow us to complete the inspection process, which includes writing the programs for the CMMs. The surface finish of the printed Onyx didn't cause us any problems,” Matt continues. “It was amazing how we compressed our process by using a printed 3D model before the real models arrived. 3D printing was certainly beneficial to Corin Group in this area, and we plan to adopt it as a step in standard development.”

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.