Automation as a passion

at ASS Luippold Automation Systems & Service eK

3D printed robot grippers in automation and robotics

ASS Luippold Automation Systems & Service eK, based in Keltern near Pforzheim, implements automation and process solutions. From planning and design to the implementation of complete production lines, they support every project with expertise and passion.

The machines are used in a wide variety of industries throughout Europe, primarily in the printed circuit board industry.

Project goals

Lightweight yet stable components for robotics

Elmar Daubenmaier, Head of Design at ASS Luippold, had already gained experience with additive manufacturing during his studies and privately. Previously, they had various parts printed by service providers using the SLS process. To bring this production step in-house and thus gain independence, Mr. Daubenmaier looked for a suitable 3D printer for production and found it in Markforged.

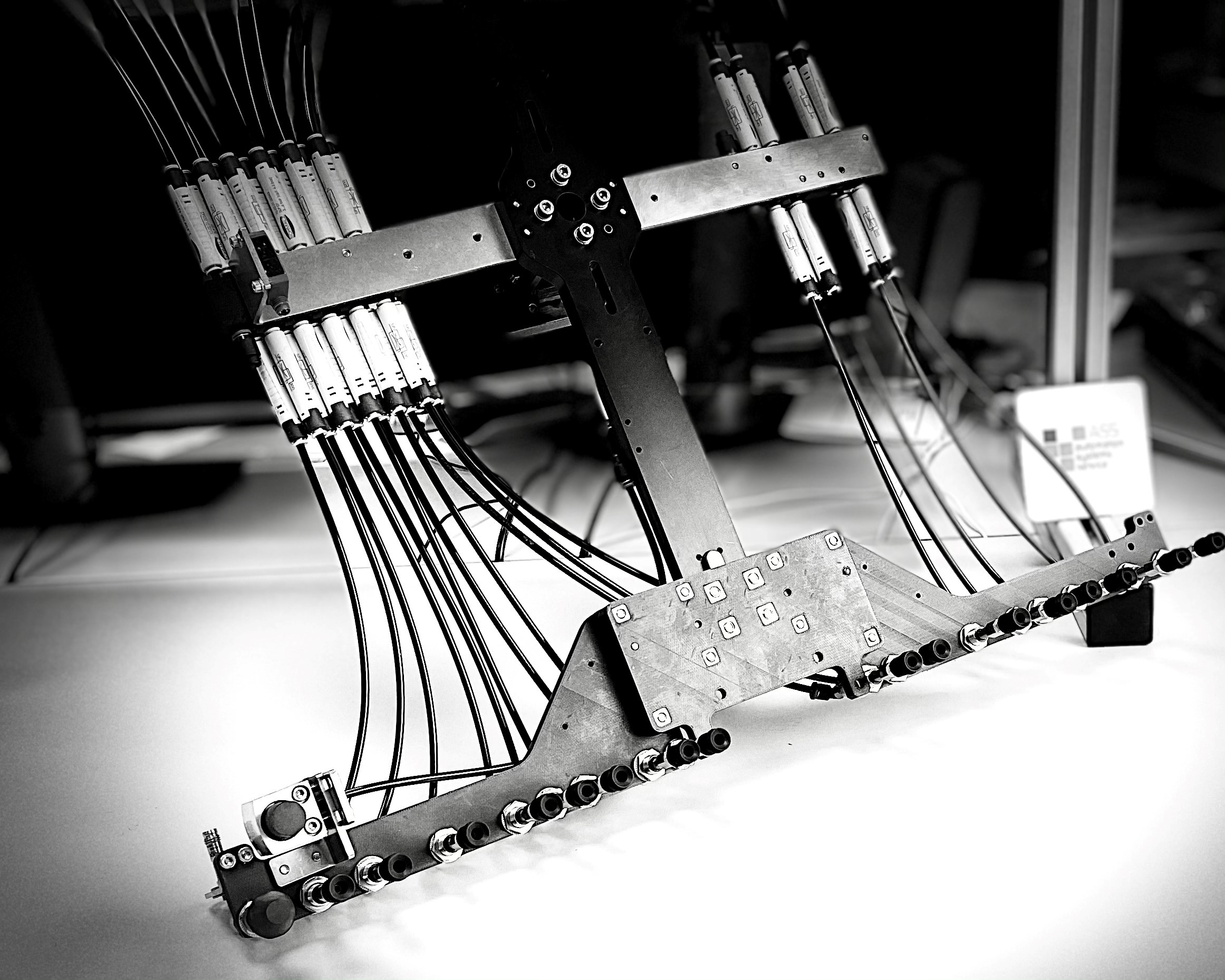

The requirements for the printed components were stability while maintaining the lowest possible weight. Robots used for circuit boards, for example, can only transport a limited amount of weight, with the circuit board sometimes accounting for half of the total. To avoid having to switch to the next heavier model, all grippers had to be as light as possible without sacrificing stability. Furthermore, Markforged 3D printers can achieve extreme weight savings compared to aluminum parts.

At a glance

Implementation

Every company has parts that can be manufactured additively!

Management was easily convinced. Thanks to the sample component custom-printed for ASS Luippold, they were able to test it directly under real-world conditions and verify its reliability.

After installation, expectations were even exceeded, and the colleagues were positively impressed. The designers developed a completely new, innovative way of thinking thanks to the new manufacturing freedom. "The new technology was also not a challenge to use, as the printer and software are incredibly easy to learn and operate. Maintenance is also not a problem for us as mechanical engineers."

Whenever we had questions or problems, the fast and competent support from Mark3D always helped us quickly!” says Elmar Daubenmaier with satisfaction.

The Markforged Mark Two is being used for full-scale production: design samples, feasibility studies, prototyping, but primarily for end-use applications for robotic gripping technology and parts required for in-house orders. Furthermore, almost all small sheet metal bent parts are being replaced with printed small parts.

But they also act as service providers, printing and developing various customer requests, from racing parts to forearm prostheses to parts for a small 3D-printed combustion engine.

Request a DEMO component now!

See for yourself how strong the components are.

Solution

You have to think differently to use the full potential

In special-purpose machine construction, all machines are essentially prototypes, but they have to function. If there are design or manufacturing errors, or if the programmer is working on the machine and needs another part at a certain point, they now only have to wait a few hours instead of several days or even weeks to receive the desired part. This has a huge impact on time to market – but also on employee motivation.

The parts have similar properties to carbon fiber parts, but cost only one-third the price and can be produced unmanned overnight or over the weekend. Complex milled parts and clamping fixtures for our CNC milling machines are printed overnight. "We also use this to produce spacers and assembly jigs for our employees. This relieves the milling department, allowing them to focus on their core business," says Elmar Daubenmaier, who also serves as technical director.

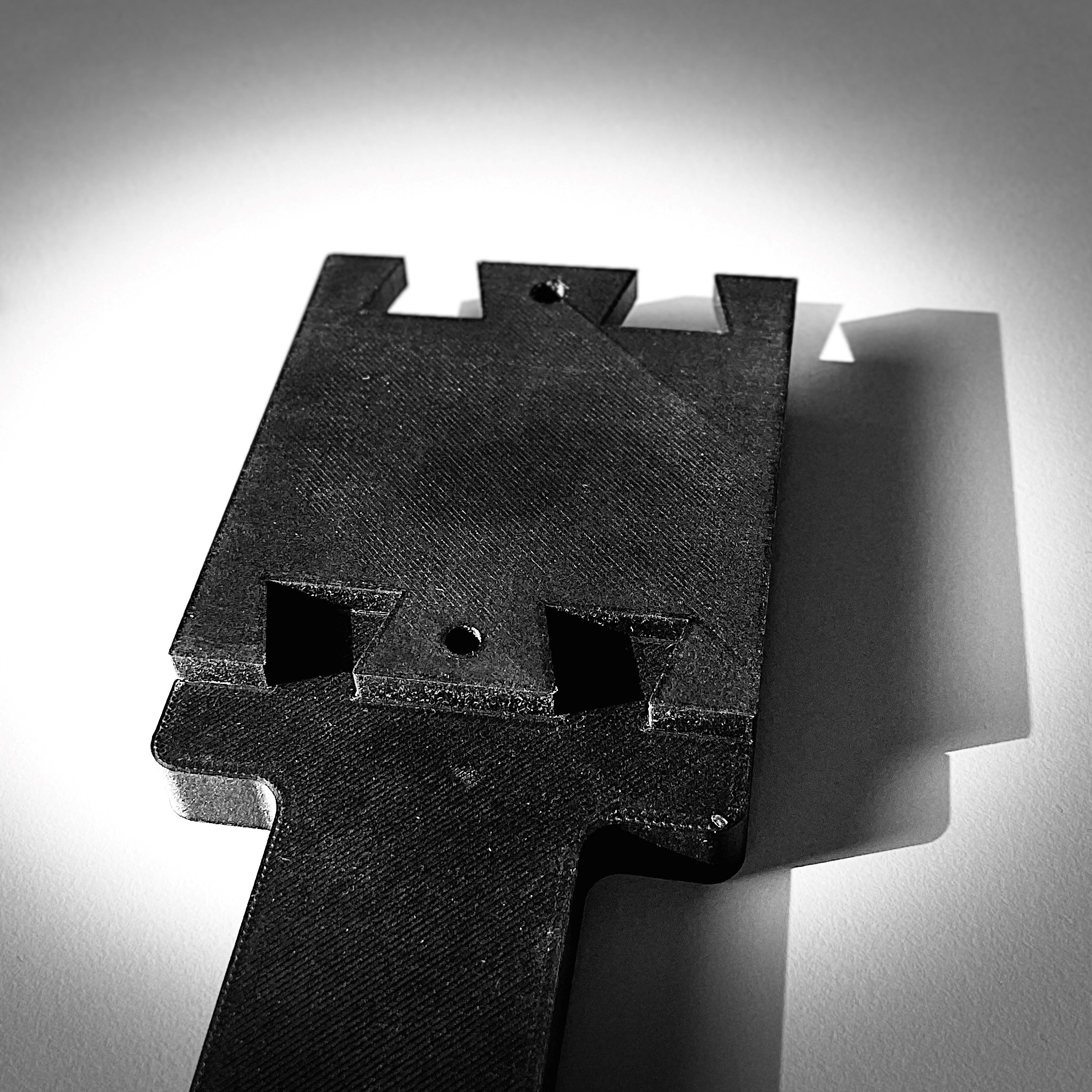

The vacuum grippers of the circuit board robots require larger components than the 3D printer can print in one piece. The design department found two solutions: Either the part is divided into three smaller pieces and screwed together to ensure a precise fit, or they are slotted together like puzzle pieces. "We were surprised at how precisely the positive connections emerge from the printer. Rework on the CAD model is rarely necessary," says Elmar Daubenmaier.

"We developed a welding machine for foam profiles. We printed all the molds required for these profiles. Conventional manufacturing would have been many times more expensive." Even a mold for coating parts of an extraction system with synthetic resin was completely printed. In addition, various other highly complex components of a sophisticated machine extraction system are manufactured with HSHT fiberglass reinforcement.

Mr. Daubenmaier is often asked how they could implement 3D printing in their company. They're thinking about a 1:1 implementation. "But sometimes you just have to think outside the box to utilize the full potential of additive manufacturing!" ASS Luippold was also able to disprove the misconception that plastic parts aren't stable enough with a spontaneous experiment: They needed replacement gear parts for a machine. These couldn't be obtained quickly, so they printed them and reinforced them with continuous carbon fiber. The gears were installed in December 2018, and the machine has been running with plastic gears without any failures ever since!

The future

Service with design offer

Every company has the potential to successfully implement additive manufacturing. Once you get started, more and more applications become apparent. It's important that the entire company is integrated so that all departments can work hand in hand with this innovation.

In the near future, ASS Luippold will not only further advance the development of robot grippers, but also replace more sheet metal and milled parts with 3D printing.

"We want to further expand our service offering and provide our customers with expert advice through a design offering specialized in additive manufacturing. We will also purchase additional 3D printers to be even more broadly positioned for contract work."

“The gears were installed in December 2018, and the machine has been running with the same plastic gears without any failures ever since!”

– Elmar Daubenmaier, Head of Design and Technology at ASS Luippold

Learn more about the applications with the MarkTwo!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Would you like a demo, have questions or need a quote for a Markforged 3D printer?

Contact us now!

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396-00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.