Bringing tomorrow's production into today – erler GmbH

“With the Markforged Mark Two, we have a process-safe, reliable, and innovative production machine – without additional personnel costs!”

– Michael Müller, Managing Director of erler GmbH

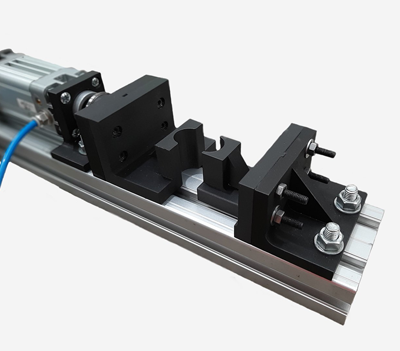

The challenge for erler GmbH was that a lot of time and money had to be spent on special machine construction as well as on individual and development parts production.

Previously, the workpieces were outsourced to various suppliers for external production. The goal was to bring the added value in-house to achieve greater flexibility, independence, and cost-effectiveness.

The advantages for erler GmbH:

✅ Flexibility

✅ Independence from suppliers

✅ Prototypes and feasibility studies

✅ Tensile strength and quality

✅ Project-specific, individual parts

Request a DEMO component now!

See for yourself how strong the components are.

Learn more about the applications with the desktop series!

How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed some information sources that will help you get the answers you need.

Leave A Comment