3D printing in electric aviation

with VOCUS GmbH

VOCUS GmbH was founded in 2019 to advance additive manufacturing in research and development and rapid prototyping. The primary goal is to make production for the aviation industry more efficient, more innovative, faster, and more cost-effective.

One of the exciting research projects is the development and production of a plug-in hybrid powertrain for aviation applications, which we discuss in more detail in this report.

Project goals

Precise and safe components

AdvanTec GmbH is the parent company of VOCUS GmbH and VisionZero GmbH. AdvanTec has been designing for Airbus Helicopters (EC135, H145, NH90) for over 20 years. In the large aircraft sector (A320, A350, and A380), it has co-designed key components for cargo and passenger doors. This has enabled the company to build extensive expertise in the requirements of the aviation industry.

VOCUS's core business consists of the production of prototypes, pre-production runs, and small series using additive manufacturing for the aerospace, medical technology, and mechanical engineering industries. For example, VOCUS prints aerodynamic fairings that are already used in series production. The aircraft manufacturer is responsible for the approval of the parts through the overall certification of the aircraft. VOCUS acts as an "extended workbench" here.

These include Class II mechanically stressed parts used in small-batch production. Until now, these parts could only be manufactured conventionally with a high degree of manufacturing variation. These parts contain, for example, a predetermined breaking point that must break under overload but must not break below this limit.

Additive manufacturing enables significantly more precise manufacturing tolerances and is printed on the Markforged X7 with Onyx and continuous carbon fiber.

Here, VOCUS succeeded in manufacturing this component with great precision and optimizing its topology for additive manufacturing. Of every 10 parts delivered in each batch, one part is destroyed in a stress test to demonstrate product requirements and production accuracy. So far, no complaints have been received.

At a glance

Implementation

Additive manufacturing for battery strings

VOCUS additively manufactures various prototypes, pre-series, and small series for aircraft components in the areas of aerodynamic fairings, connections, cockpit equipment, landing gear, antenna fairings for on-board Wi-Fi routers, and proprietary developments, such as a battery pack for electric aircraft propulsion.

AdvanTec is currently conducting two research projects in the field of electric aviation. The E-ROP project, which is nearing completion, involves the integration of a hybrid-electric propulsion system for a single-seat aircraft. A powertrain consisting of a battery pack, control electronics, a range extender, and a FES (Front Electric Sustainer) drive system has been developed for this project.

The maiden flight is planned for May/June 2021. The goal is a battery-electric flight of 350 kilometers without a stopover.

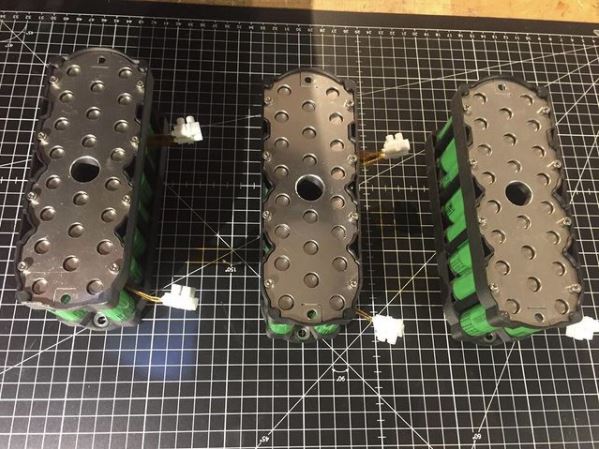

Another AdvanTec project is driving the further development of existing battery technology. The battery modules are currently being tested for various stress scenarios, such as overheating. The cell holders printed from Onyx FR must not continue to burn independently if an individual cell catches fire. If the test results are positive, these battery strings will be series produced and used in the research aircraft. This battery technology could then also be used for other aircraft. The necessary approval modalities are already taken into account during the development phase. Manufacturing on Markforged 3D printers not only enables VOCUS to quickly move from prototypes to series production, but is also very cost-effective and time-saving, as production does not require any tooling. "Our battery modules have roughly twice the power density of the batteries previously used in this aircraft," says Stefan Senger, CEO and Head of Development at AdvanTec and VOCUS GmbH.

Request a DEMO component now!

See for yourself how strong the components are.

Solution

Flying 2,000 km emission-free and unmanned in the future

For the battery cell holders, VOCUS uses Onyx FR, a self-extinguishing and flame-retardant material that is processed using the Markforged X7.

"Once this battery can be installed, we will be able to achieve a range of 700 kilometers with our research aircraft. In a further development stage, the range extender (REX), a rotary engine with a generator, will be integrated into the aircraft, thus increasing the range to up to 2,000 km non-stop. In the final development stage, the REX will be replaced by a hydrogen fuel cell, thus achieving one of our goals, "emission-free aviation." "We are pursuing this vision with great passion, but we still have a long way to go in terms of development," says Stefan Gorkenant, CEO and Head of Marketing at AdvanTec and VOCUS GmbH.

Another project focuses on optimizing a BMS (Battery Management System) for electromobility systems. The goal is to increase efficiency and optimally monitor battery systems. Here, too, AdvanTec and VOCUS GmbH are consistently utilizing the Markforged Printfarm for rapid prototyping and pre-production and small-batch production. "Not only battery technology is facing leaps in development here, but also all peripherals, such as module design and cell monitoring. Additive manufacturing is a key to implementing developments quickly and cost-effectively," explains Stefan Gorkenant.

"We were able to significantly accelerate our research projects in the field of new electromobility with the hybrid powertrain. We more than halved the time required for iteration loops in sub-development, for example, for the battery holders, thereby drastically reducing costs. No expensive tools had to be manufactured, which enabled us to work independently."

– Stefan Senger, CEO of AdvanTEc and VOCUS GmbH

The future

Great potential in aviation

VOCUS currently operates one Keyence and four Markforged 3D printers (one X7, two Mark Twos, and one Onyx One). The X7 allows them to fully exploit its potential for aerospace applications, as it can print with the flame-retardant Onyx FR material.

VOCUS also offers design and 3D printing services for the aerospace, medical technology, and mechanical engineering sectors.

“We want to offer our skills and experience to our customers, which has now been well received.”

At VOCUS GmbH, 10 engineers and 5 product designers have over 20 years of combined expertise in the aerospace industry. Looking ahead, Stefan Gorkenant has taken a look at the Markforged Metal X to determine the right materials for their next project, whether copper, steel, aluminum, or Inconel. Ceramic is also an interesting material.

There is huge potential for additive manufacturing in the aviation sector – and exciting developments are expected in the coming years!

NASA JPL relies on Markforged 3D printers

NASA JPL's CoSTAR team is the leading institute for robotic exploration of the solar system and is using Markforged technology to push the boundaries of subterranean research as part of the DARPA Subterranean Challenge.

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Would you like a demo, have questions or need a quote for a Markforged 3D printer?

Contact us now!

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.