Replacing aluminum components with 3D printed carbon fiber

Recently, a severe aluminum shortage among industrial suppliers has led to sharp price increases. Since January 2021, aluminum prices have risen by over 50%, and experts expect the increase to continue over the next two years.

According to Jyske Bank, the global aluminum shortage is due to increased material consumption based on three factors: increased spending on consumer goods due to economic stimulus packages, increased investment in sustainable technologies that rely on the use of aluminum (e.g., wind turbines, electric cars), and Chinese production and consumption of aluminum.

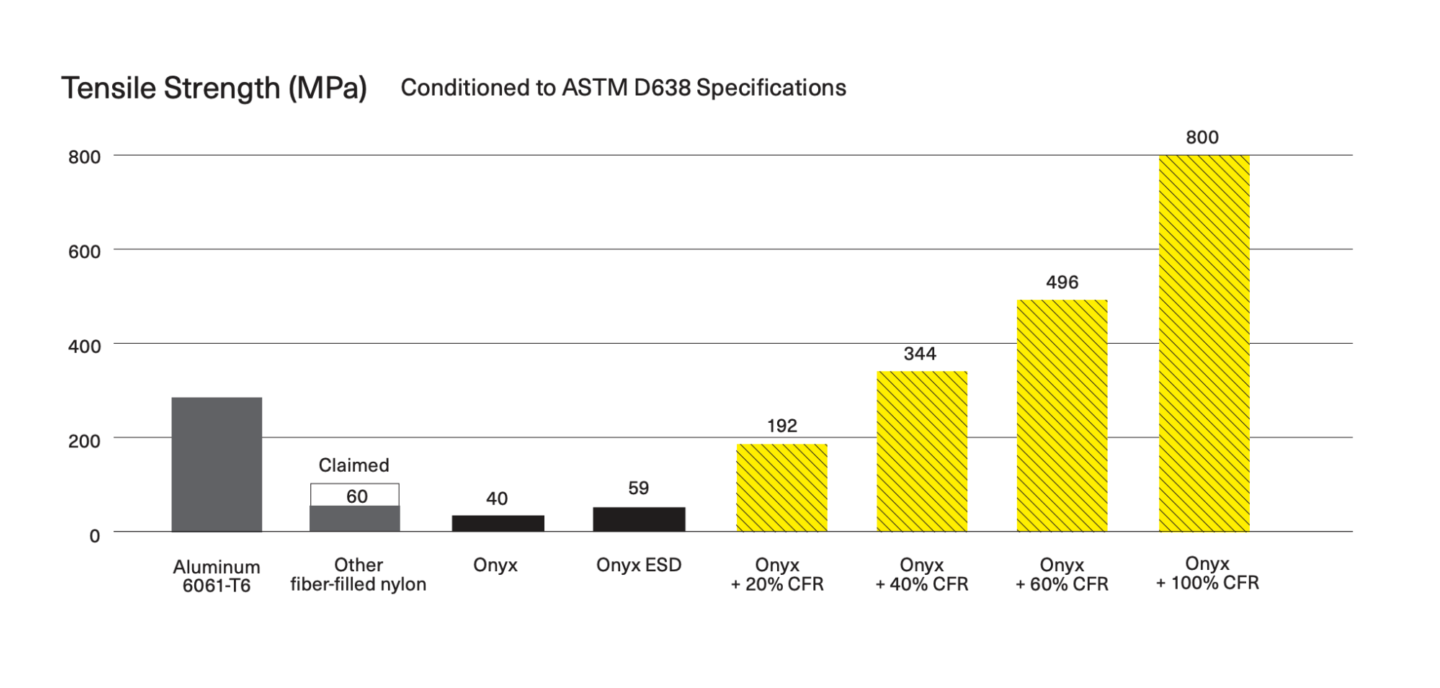

Given this aluminum shortage, Markforged carbon fiber offers a suitable alternative. Many of our customers use it to replace machined aluminum parts. Carbon fiber has the highest strength-to-weight ratio among our continuous fibers. It is six times stronger and eighteen times stiffer than Onyx and is often used for components that replace machined aluminum.

When embedded in a composite base material like Onyx, it can produce parts as strong as 6061-T6 aluminum. As a material, it is extremely stiff and strong and can be automatically embedded by Markforged 3D printers in a variety of geometries to produce optimized parts.

Request a DEMO component now!

See for yourself how strong the components are.

What is carbon fiber?

Carbon fibers consist of carbon atoms arranged in long, crystalline fibers with a diameter of only 5-10 micrometers. In modern manufacturing, several thousand carbon fibers are bundled into strands and combined with other materials to create a composite material. Combined with a thermoplastic or thermosetting resin matrix, carbon fibers can take on various forms used in technical applications.

The specific material properties of carbon fibers make them ideal for a wide range of applications, including

What makes carbon fiber an ideal replacement for aluminum?

Continuous fiber reinforcement (CFR) technology allows carbon fiber to achieve strength similar to aluminum while replacing machined components. This is due to its increased stiffness, impact resistance, heat resistance, and durability.

CFR offers the user the possibility to flexibly incorporate continuous fibers into their parts – they can control how much carbon fiber is incorporated into the parts and where exactly the carbon fibers are placed in the parts.

Properties of carbon fibers

Compared to 6061 aluminum, 3D-printed carbon fiber exhibits a 50% higher strength-to-weight ratio in bending and a 300% higher tensile strength ratio. Continuous carbon fiber reinforcement has been used to manufacture everything from precision-fit jigs and fixtures to specialized tools for some of the world's largest and most prestigious companies, as well as individual end-use parts in high-end motorsport applications.

In addition, the continuous carbon fiber reinforcement has a flexural strength of 540 MPa, compared to 6061-T6 aluminum (<480 MPa).

How does carbon fiber 3D printing work?

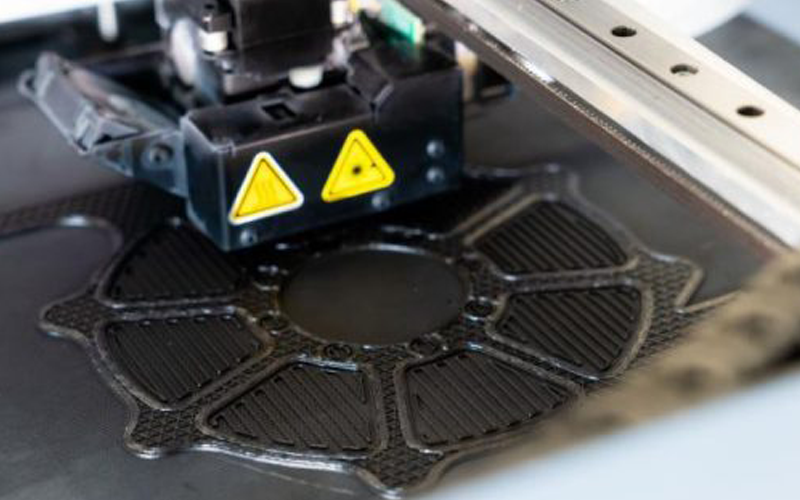

Markforged 3D printers begin by shaping the outer geometry and filling the part with Onyx, a thermoplastic resin filled with shredded short carbon fibers. This process step is called Fused Filament Fabrication (FFF).

A second nozzle then inserts continuous fiber reinforcement (CFR), which can be used to selectively reinforce the perimeter, specific features, or entire layers of the part. CFR allows parts to be strategically reinforced in different ways to meet various specific loading conditions.

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Thank you for the great work you do.

Kind regards, Mia