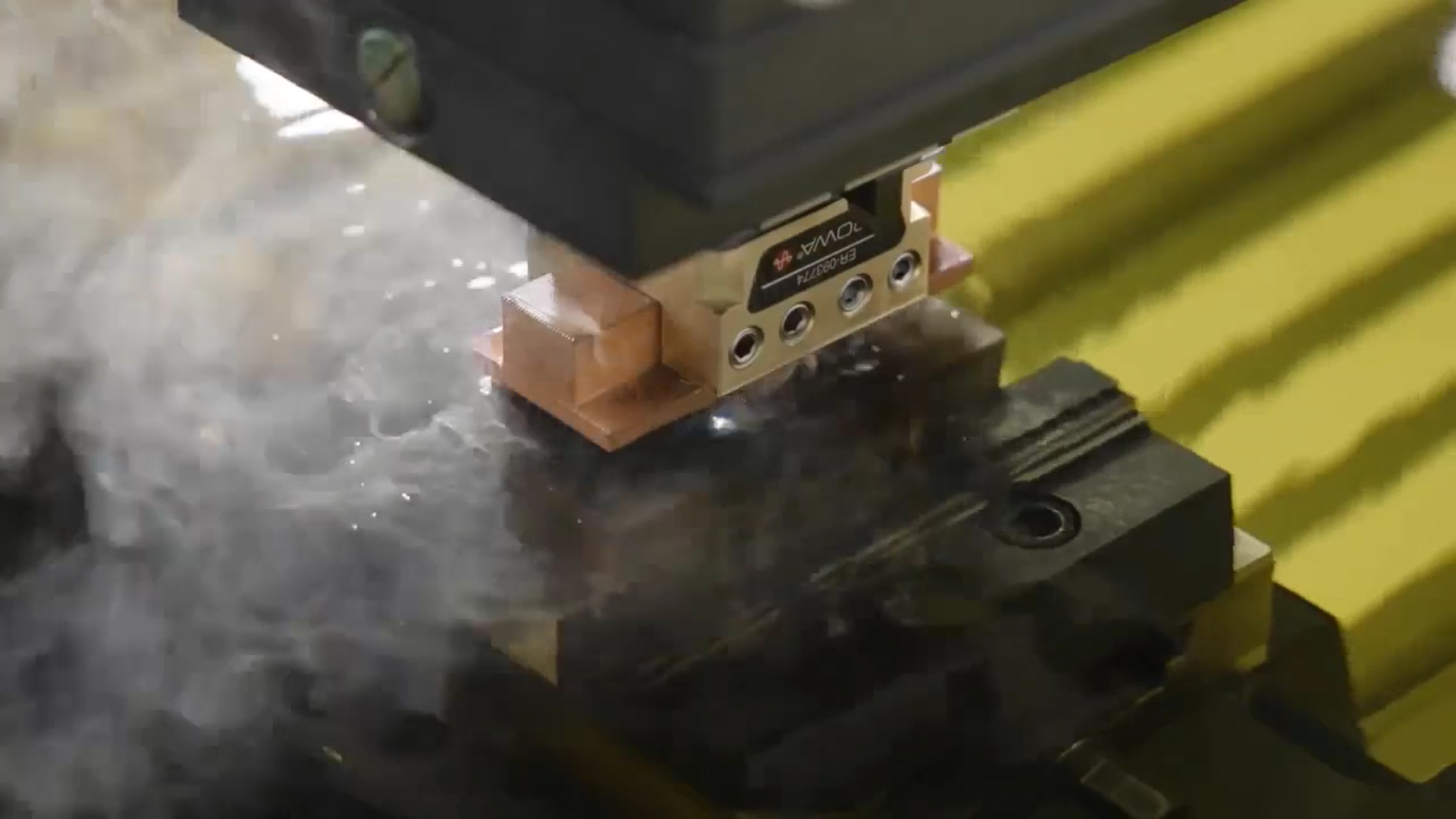

Additively manufactured copper sinking electrode

Many companies are accustomed to using the die-sinking EDM process when manufacturing injection molds.

The TITANS of CNC MACHINING have always used a CNC machine to produce these countersink electrodes.

However, the effort and costs involved are very high for the small quantities.

Now you can produce these copper sinking electrodes on the Markforged Metal X with complete ease.

In the video we show in detail how the positive copper mold burned a beautiful negative mold into the stainless steel block.

Material removal doesn't occur through direct contact between the workpiece and the electrode. As soon as the electrode is close enough to the workpiece, the spark jumps and burns away the material. – The result is significantly better than expected!

When we think about copper sinking electrodes in the future, we should keep the Metal X in mind!

👉 Learn more about the Markforged Metal X system: https://www.mark3d.com/de/metalx/

Request a DEMO component now!

See for yourself how strong the components are.

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Leave A Comment