Autoliv relies on Markforged for the production of devices, tools and functional prototypes

The company

With around 60,600 employees in 28 countries and a turnover of around EUR 8.2 billion, the supplier of safety systems for the automotive industry is a global leader.

Autoliv develops, produces and supplies seat belts, airbags, steering systems and electronic safety products.

Mechanically and thermally resilient components from the additive manufacturing machine

Autoliv's core business is the manufacture of safety components for the automotive industry, in particular seat belt systems. The production of viewing samples and functional prototypes as well as devices for development was

This is a challenge due to the diversity of the areas of application.

The company was looking for a solution that could be operated using the plug & play principle, reliably produce components and withstand the extreme requirements of Autoliv and the automotive industry.

Group Leader Component Shop at Autoliv in Elmshorn, Jan Jabusch, provides insights into the Group's use of additive manufacturing.

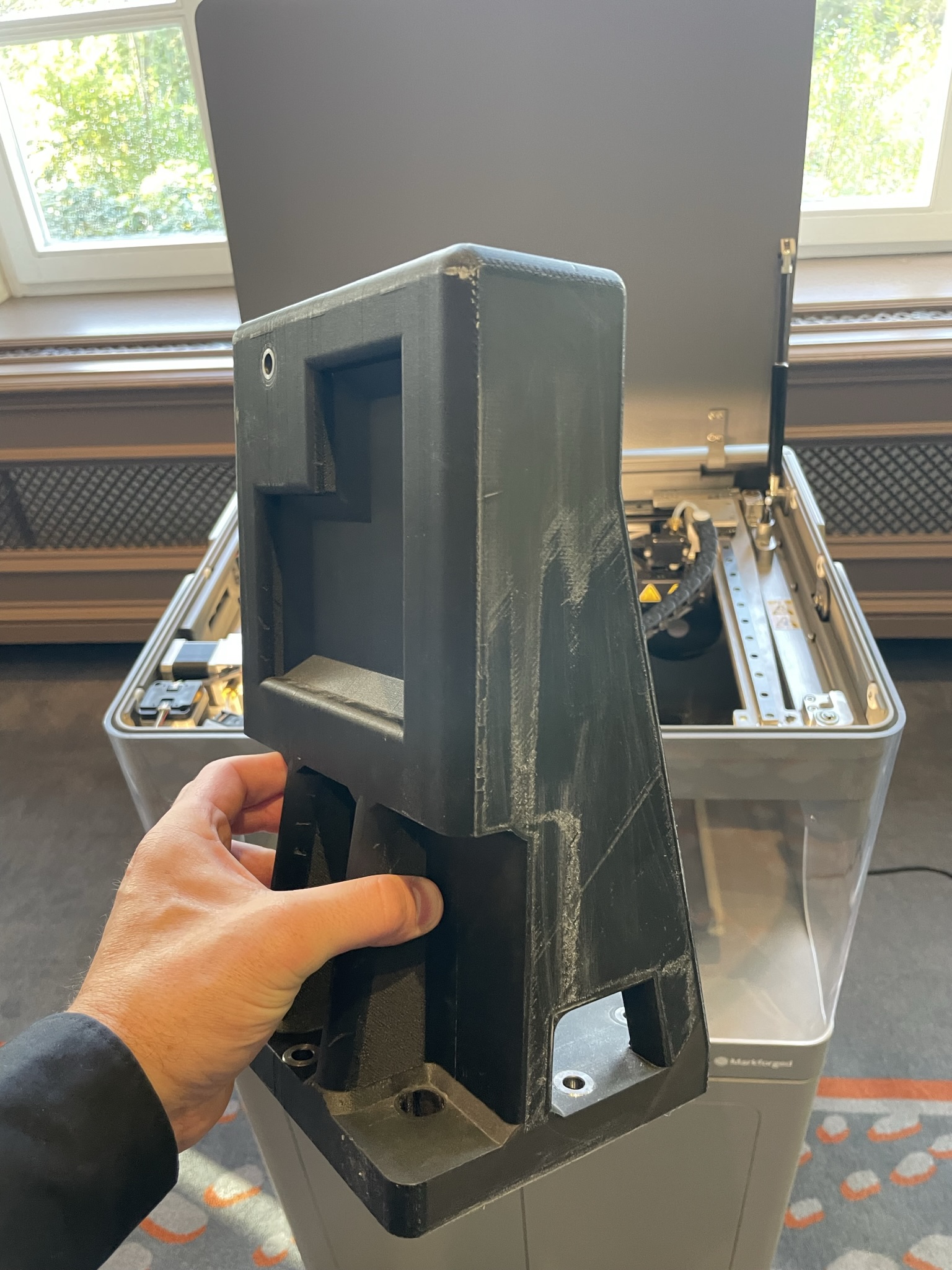

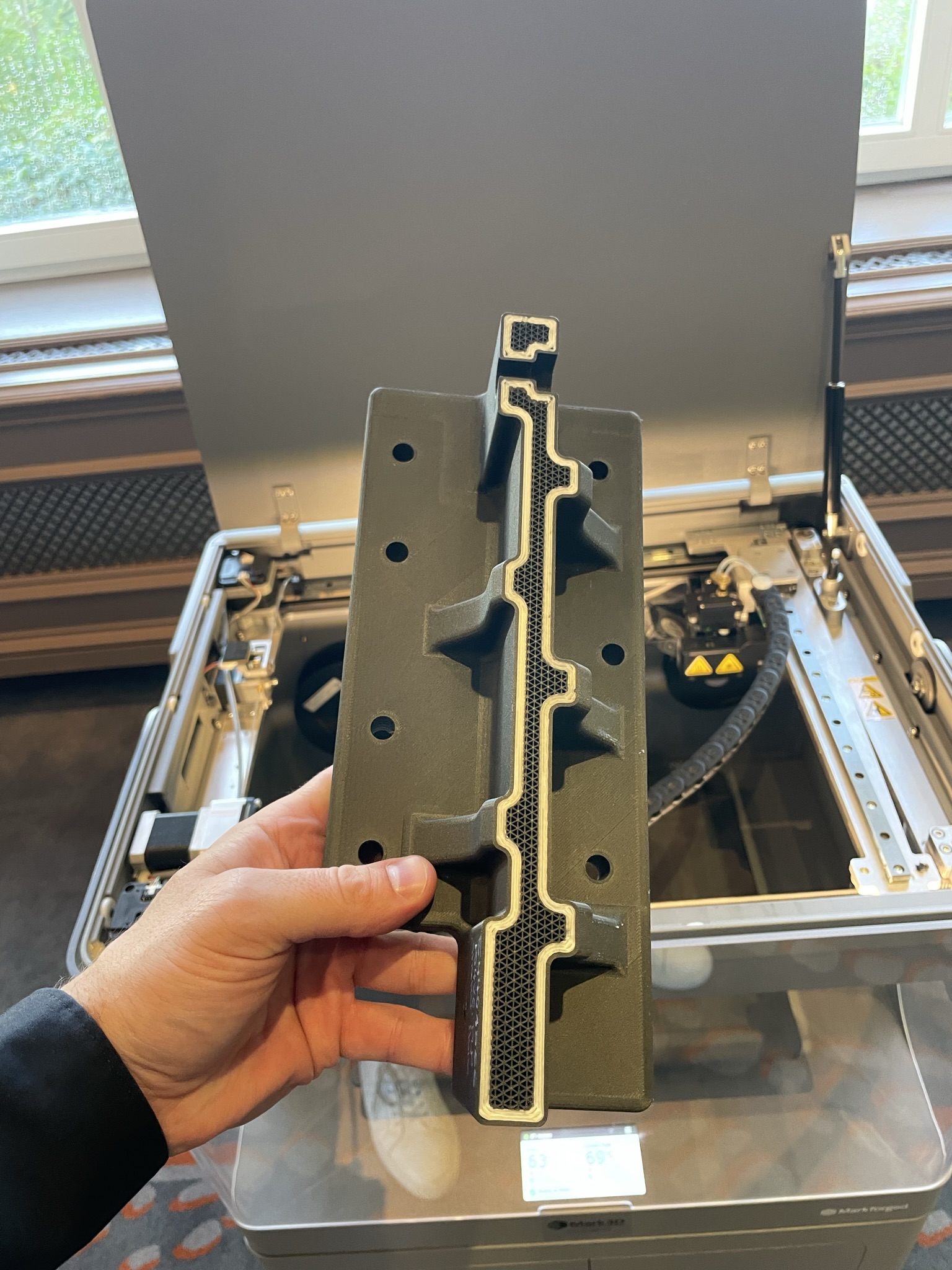

The focus of the project is the development of a clamping device for a shaker test.

An additive manufacturing technology that speeds up development times at Autoliv?

Jan Jabusch discovered composite 3D printing with Mark3D - Markforged at a trade fair in the region. This technology makes it possible to insert continuous fibers in the form of carbon, Kevlar or glass fiber into the component.

"The decision to invest in Markforged technology was based on the strength of the material and the ability to insert continuous fibers. Other points were the easy handling of the printer and the very good print quality," explains the head of prototype construction.

Mechanically resilient components that achieve the strength of aluminum with a heat deflection temperature of 145°C.

Industrial 3D printing and materials enable the production of equipment such as fixtures and fixtures, which bring many performance advantages to manufacturing.

Request a DEMO component now!

See for yourself how strong the components are.

"The decision was made due to the strength of the material and the possibility of inserting fibers. Other points were the ease of use of the printer and the very good print quality."

- Jan Jabusch, Group Leader Component Shop, Autoliv B.V. & Co. KG

At a glance

Today, numerous components are printed on a daily basis. Autoliv already uses the Markforged 3D printers Mark Two and Onyx One as well as the X3 and X7 from Markforged. The Markforged Metal X system is also used to produce metal components.

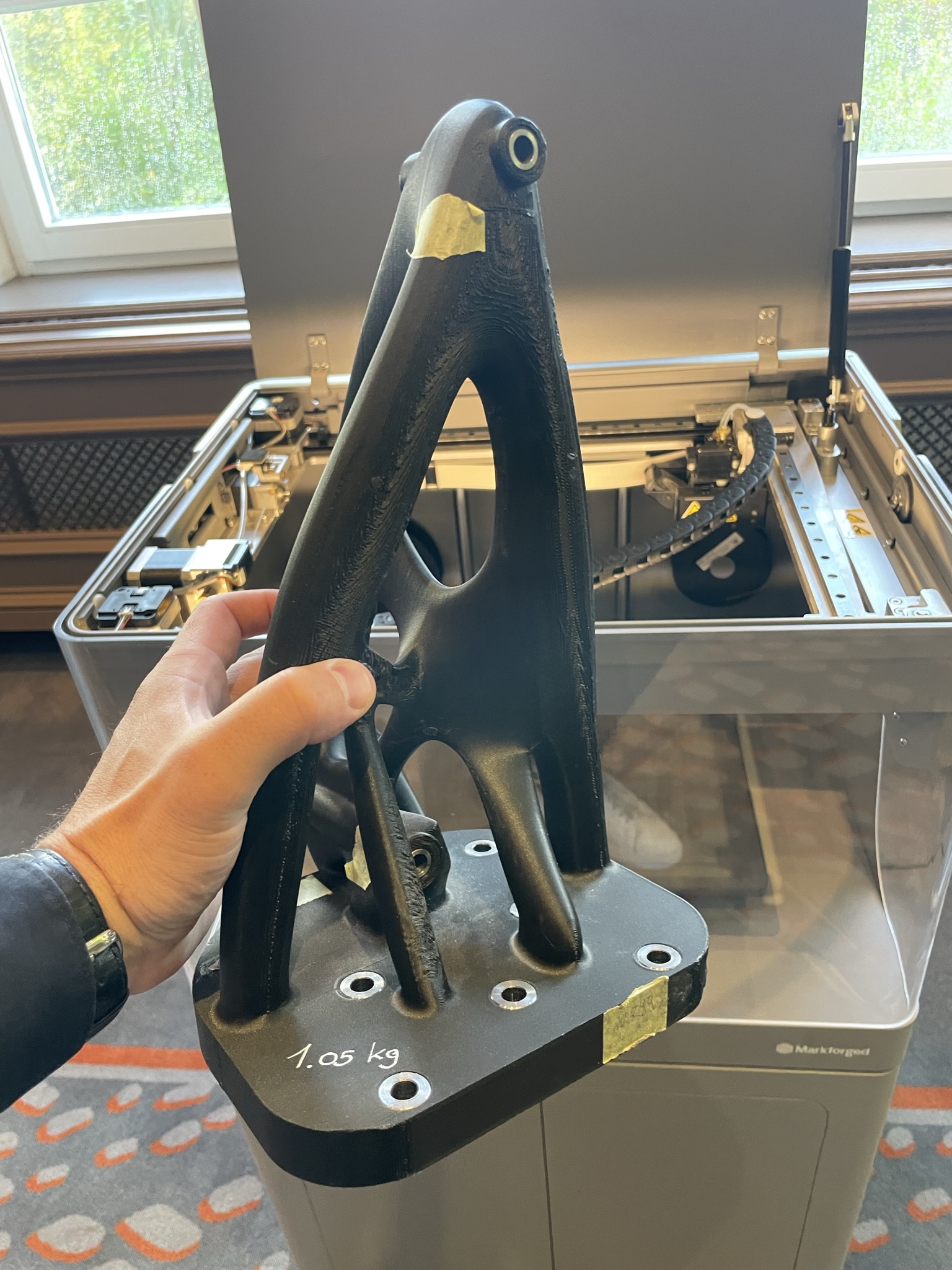

Sample parts for development, devices of all kinds, forming tools. Among them: Gears, covers and caps for the products, components from the products, clamping and forming fixtures, shafts, sheet metal and much more. 3D printing streamlines and improves the production of these tools, resulting in higher productivity and better ergonomics. For Autoliv, the technology is much more than just rapid prototyping.

Around 15,000 hours of printing time per year speak for themselves. And all Markforged 3D printers are extremely low-maintenance.

Practical example of a clamping device for a shaker test

This test is standard in the automotive industry and must be carried out on new products. The load is 30000 cycles with at least 1G load.

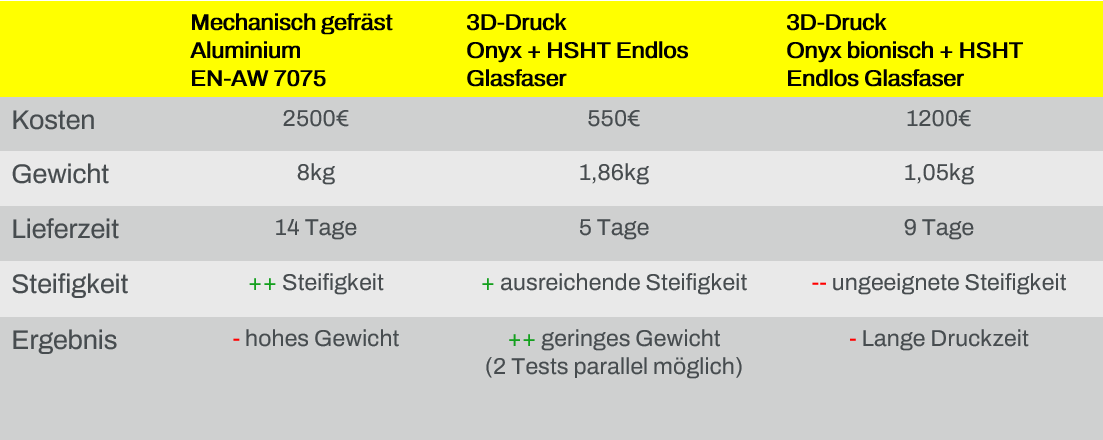

Three different versions of this device are compared:

The biggest advantage of this example is that Autoliv saves 6 kg in weight and can therefore test two parts in one test run. An enormous added value for the company.

Solution

Autoliv decided to use Markforged 3D printers to simplify the production of prototypes and sample parts for its safety components, resulting in time and cost savings.

15,000 printing hours in 2020 and 16,000 printing hours were achieved in 2021. Jan Jabusch plans to further expand the use of Markforged 3D printers.

The savings are not directly reinvested, but are used for the earlier implementation of ideas in series production.

The potential of the new Markforged FX20 industrial 3D printer for Autoliv is currently being tested. The possibility of increasing throughput and producing even larger components could be another success story for Autoliv.

Would you like a live demo, have questions or need a quote for a Markforged 3D printer?

Contact us now!

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.