Digital Source

Get unlimited spare parts with one click

Digital Source

Get unlimited spare parts with one click

Consistent, factory-ready component quality.

Software, printers, and materials work seamlessly together on a unified platform. The Digital Forge is purpose-built to deliver unrivaled quality and consistency – anywhere in the world.

Licensed digital components, directly from the source.

Manufacturers upload their part designs to a digital warehouse where customers can find and purchase licenses for 3D printed parts.

Immediate on-site printing or outsourcing for flexible processing.

Customers can print critical components on-site the same day or access a list of vetted print service providers to order printed parts in bulk.

No back and forth when purchasing.

No shipping. No customs delays. Just press print.

Reduce paperwork and time-consuming processes.

Simpler spare parts processes improve employee productivity and customer satisfaction.

Say goodbye to storage costs.

Improve profitability by reducing waste from overproduction, inventory costs, shipping and taxes.

How does Digital Source work?

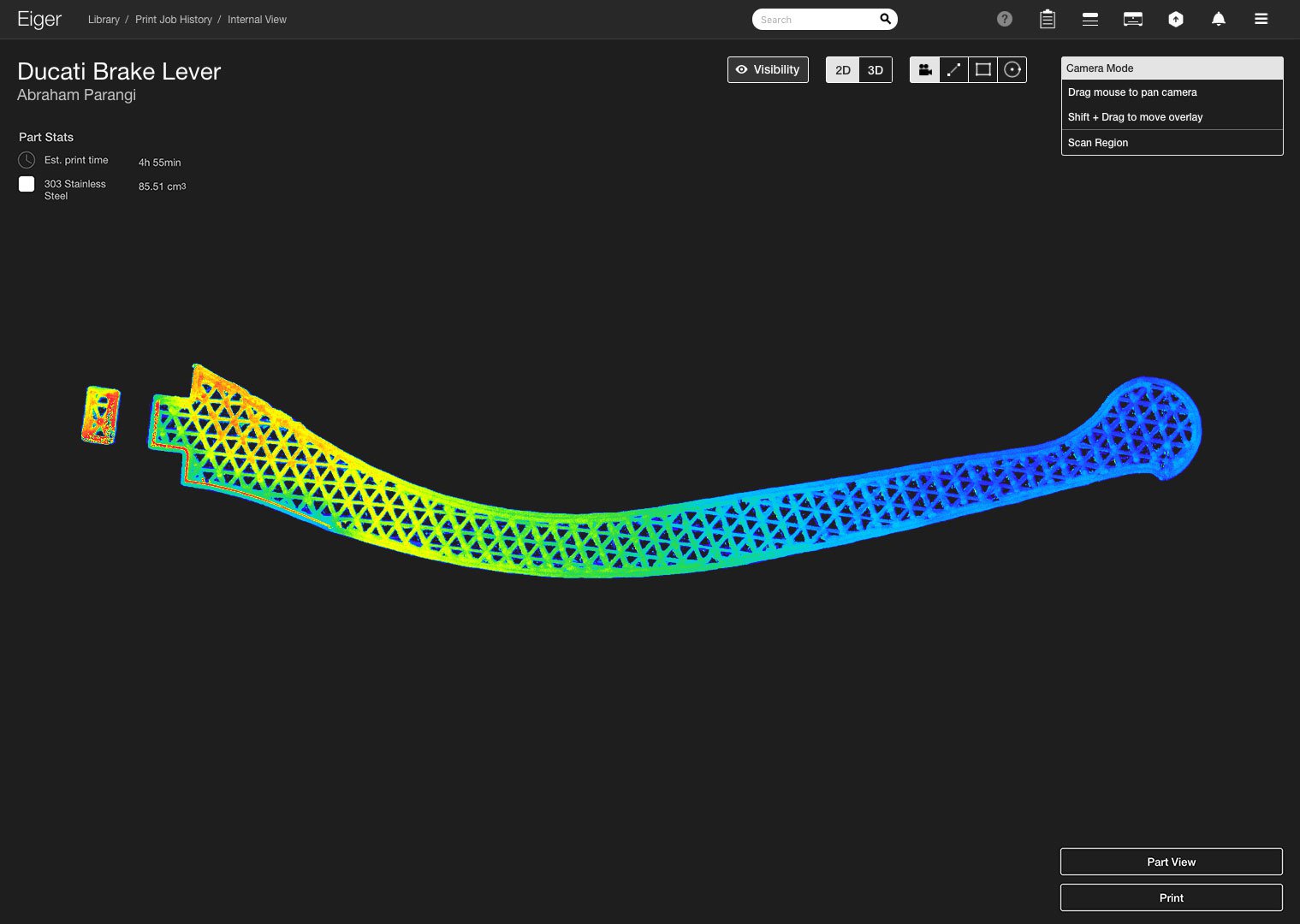

Upload your part and then specify the printing process requirements. Approved customers can search digital catalogs and print parts, but they cannot download, modify, or recreate the design.

Manufacturers get paid for their part designs, and customers get the flexibility to print parts when and where they are needed.

"Time is very valuable to us—a line downtime in one of our factories is a big deal, but a broken turbine can cost even more. If we can access and print the required part, we can get the plant or turbine back up and running much faster."

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Would you like a demo, have questions or need a quote for a Markforged 3D printer and the EIGER software?

Contact us now!

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396-00

E-mail: markforged@mark3d.de

To contact us, please fill out our secure form.