Markforged Carbon 3D printing and continuous carbon fiber 3D printing

Here’s what you should know about Markforged Carbon 3D printing:

Why continuous fibers and carbon 3D printing?

Carbon fiber is only optimally designed to withstand tensile and compressive forces if the force acting on the component is applied in the direction of the fiber grain. If the carbon fiber is interrupted during the construction process, it can no longer absorb the optimal tensile and compressive forces. This is why the continuous fiber is so crucial for the stability of a component printed with carbon fiber, Kevlar®, or glass fiber. Continuous fiber-reinforced 3D printing thus ensures strength at a completely new level.

What is Markforged continuous carbon fiber?

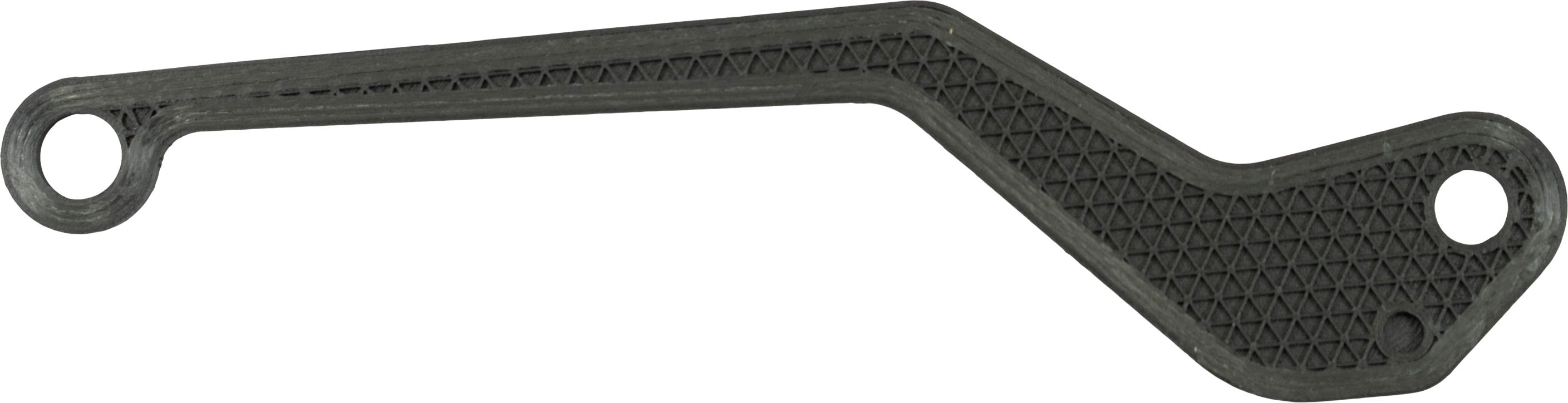

Markforged continuous carbon fiber is the stiffest and strongest fiber with the highest strength-to-weight ratio. This allows for the printing of mechanically and thermally resilient components that exceed the strength of aluminum. Components that previously required cost-effective milling can now be printed cost-effectively overnight.

When should you print with continuous carbon fiber?

Continuous carbon fiber is strong enough to replace aluminum at half the weight. Use carbon when you want high stiffness and minimal deflection.

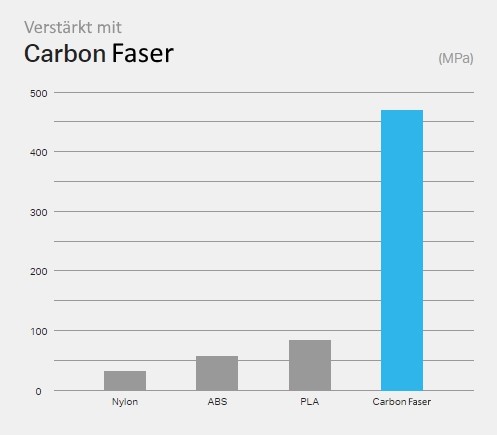

Flexural strength

When bending at three points, our 3D printed carbon fiber is 8 times stronger than ABS and 20% is stronger than the bending limit of aluminum.

Request a DEMO component now!

See for yourself the mechanical strength of continuous carbon fiber.

Carbon 3D printing: What is the difference between a carbon short fiber and a carbon continuous fiber?

Carbon fibers are highly valued in engineering for their strength-to-weight ratio, especially in tension applications.

When you combine the fibers with a matrix material to allow them to be shaped, they form incredibly lightweight, strong structures because the optimal arrangement of the fibers takes advantage of their tensile properties.

However, when short carbon fibers are blended with a thermoplastic such as ABS, PLA, or nylon, the continuous strength of these fibers is not utilized. A continuous fiber, however, forms a continuous bond across the component's load-bearing surfaces, evenly distributing the load and thus withstanding it.

The Markforged ONYX contains short fibers (PA6+ short carbon fibers) and can optionally be reinforced with continuous carbon fiber. This is inserted into the part via a second nozzle in the print head.

This concept makes the continuous fiber so much more efficient than the short fibers!

Practical report:

Wärtsilä produces first CE-certified, 3D printed component

Wärtsilä is a global leader in intelligent technologies and system solutions for the marine and energy markets, with a product portfolio ranging from engines to propulsion and renewable energy.

The tool, made of Onyx with continuous carbon fiber, underwent various tests and inspections, resulting in the first 3D printed, CE-certified lifting tool.

“The beauty of 3D printing is that any design can be printed anywhere, anytime, even on the cargo ships that Wärtsilä helps maintain.” – Juho Raukola, Head of Additive Manufacturing

FAQ about carbon 3D printing

What is continuous carbon fiber?

Continuous carbon fiber is a thin filament composed of carbon atoms arranged in a crystalline structure. Due to its very high stiffness and strength, it is widely used in the aerospace and automotive industries.

How strong is the continuous carbon fiber?

Carbon fiber has a flexural strength of 540 MPa (78.3 ksi), which is higher than the yield strength of 6061 aluminum. Its tensile strength is 800 MPa (116.0 ksi), more than twice that of aluminum. Further information on the material properties of continuous carbon fibers can be found in the datasheet.

How much does continuous carbon fiber cost?

A 50 cc spool costs €165.00 including VAT and a 150 cc spool costs €450.00 including VAT.

Learn more about carbon 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Would you like a demo, have questions or need a quote for a Markforged X-Series printer?

Contact us now!

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396-00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.