Use of Inconel 625 for fast and repeated temperature cycling

Nieka Systems manufactures sample preparation equipment that enables its customers in the mining and cement production industries to analyze and ensure the quality of their manufacturing processes. Nieka Systems' machines convert ore or cement samples into glass slides, which are later used for precise compositional analyses of the samples.

Challenge

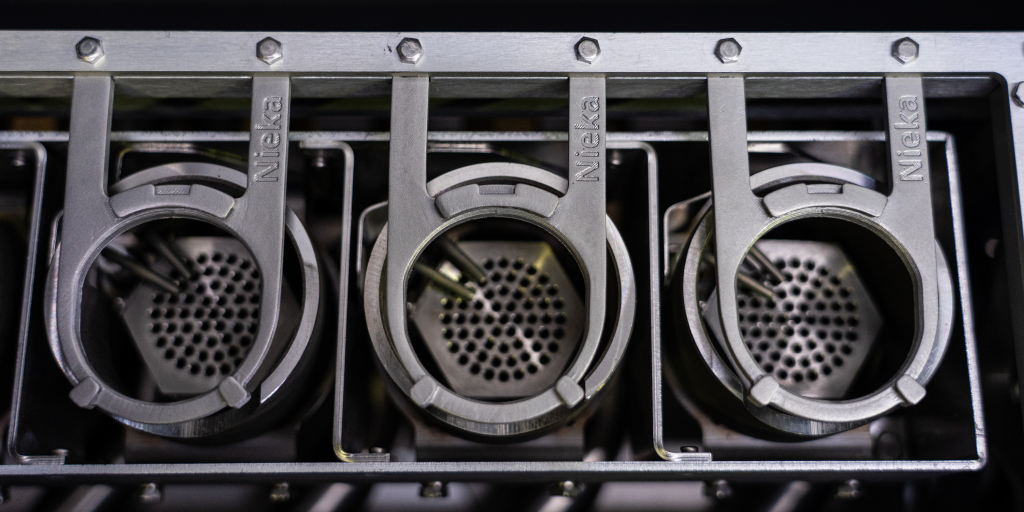

The material samples are melted in a platinum crucible and then poured into a heated platinum mold. The melting process takes place at temperatures up to 1000°C, after which the mixture is poured into a mold and rapidly cooled. Because of these repeated, rapid temperature changes, the internal components in Nieka's melting instruments must be made of materials that can tolerate high temperatures and keep up with rapid temperature cycling.

Because Inconel is a nickel-based superalloy capable of withstanding temperatures up to 1000°C, it was a natural choice for the clamps that hold the crucibles and molds in place via gas burners. Nieka Systems initially explored CNC machining as an option for manufacturing the Inconel crucible clips, but found the costs were well beyond their budget and the lead times were too long. They then turned to 3D printing service bureaus to outsource 3D-printed Inconel 625 crucible clips using DMLS (Direct Metal Laser Sintering) technology. The costs of outsourcing part production using DMLS were initially very attractive, but began to add up, and lead times were highly variable and difficult to predict. The team became increasingly concerned about whether they would be able to keep up with product demand, as they had already made their equipment available in 20 countries around the world.

Solution

Following the success of DMLS Inconel crucible clips—but seeking lower costs and faster, more predictable lead times—Dr. Louis Croisetière, founder of Nieka Systems, decided it was time to bring manufacturing in-house. He sought to reduce outsourcing costs and improve lead times, but wanted a solution that was safe, easy to use, and within his budget. After thoroughly researching the 3D printing market, Dr. Croisetière and his team selected the Markforged Metal X system and two composite 3D printers. Nieka Systems chose Markforged based on its track record of producing proven 3D printers, emphasizing that "Markforged had a market-ready solution and years of business experience." Nieka was quickly able to adapt their previous crucible clip design and easily print it in Inconel 625 on the Metal X system. The clips have already proven their worth after passing Nieka's internal tests and are now standard in its worldwide production units.

Since introducing two types of high-performance Markforged 3D printers into production, Dr. Croisetière and his team have seen a transformation in how far they can push the design of their products. From composite prototypes to 3D-printed Inconel 625 production parts, their printers are used throughout the company. "For us, assembly time is reduced, and we don't have any of the design limitations we would have had if we had used traditional methods," said Dr. Croisetière. The team can now print the same batch of parts in-house 10x cheaper and in four days, instead of waiting up to four weeks, and they've saved CAD $108,000 (~USD $80,000) in part costs alone within a year.

At a glance

Customer testimonials

“By bringing Markforged Metal X in-house, there is virtually no lead time for these parts.”

– Dr. Louis Croisetière, founder

"The Metal X system allows us to manufacture parts faster, reduce lead time, know exactly when we can deliver, and go further in the design process. And cost-wise, it was a no-brainer."

– Dr. Louis Croisetière, founder

Request a DEMO component now!

See for yourself how strong the components are.

Looking to the future

Looking ahead, Nieka Systems has accelerated its product development and minimized time to market by bringing Markforged's technology in-house. Not only has the Metal X accelerated the company's product development, but the team has also used its composite printers to create jigs and fixtures that further speed up the manufacturing process. While the Metal X system was intended only for high-temperature crucible and mold clamps, the team now uses it for other production parts as well. "Some of our new designs are based on the fact that we can print the parts, so I would say it has somewhat changed the way we work," said Dr. Croisetière.