Markforged Onyx

What is Markforged Onyx?

The blend of nylon with 15% % short carbon fiber provides a high-strength thermoplastic with excellent heat resistance, surface finish and chemical resistance.

When should you print with Markforged Onyx?

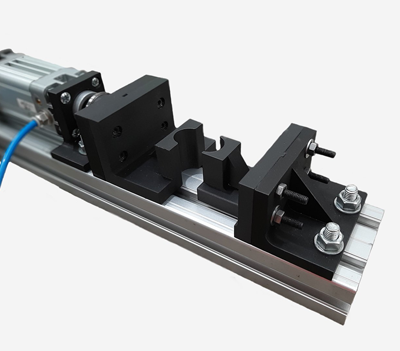

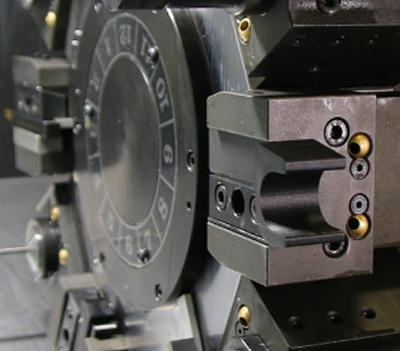

Onyx serves as the thermoplastic matrix for Markforged's composite parts. It can be printed alone or reinforced with one of the continuous fibers to achieve strength comparable to aluminum. Use Onyx for everything from tools and fixtures to spare parts.

Practical report:

Additive manufacturing as a genuine manufacturing complement at MMB GmbH

Additively manufactured components are a common thread throughout the entire operation. Almost every component is unique – the high level of customization presents MMB's designers with new challenges every day.

The Mark Two has been running for over 32,500 hours (7,210 hours per year) for about four years! The 3D printers produce complex machine components overnight, 24/7.

More and more, individual components could be manufactured overnight using 3D printers in complex machines. Initial skepticism turned into great enthusiasm for the new manufacturing technology, which delivers new added value to the company every day.

Advantages of Markforged Onyx

Designed for engineers

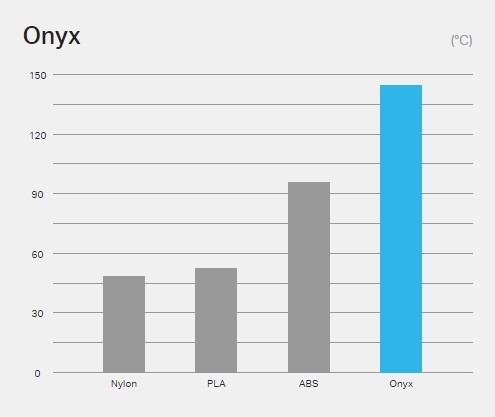

Onyx has the strength of nylon/PA6, the stiffness of fiber-reinforced plastic, and a heat deflection temperature of 145°C. Markforged Onyx is the perfect 3D printing material for all industrial applications.

You get exactly the parts you designed

The added short carbon fiber makes it possible to produce stiffer components with significantly higher surface stability.

Reduce your rework effort

The matte black color of Onyx makes it perfect for ready-to-install components. You can use your finished components directly from the build platform – without any chemical or mechanical rework.

The Markforged Material Advantage

Onyx can be further reinforced with continuous fibers such as carbon, Kevlar®, and glass fiber. Even without continuous fiber, Markforged Onyx can be reliably printed. The quality of the components far exceeds what you're already used to from conventional 3D printers. In combination with Markforged continuous fiber, you get mechanically and thermally resilient components that exceed the strength of aluminum.

Request a DEMO component now!

See for yourself how strong the components are.

Frequently Asked Questions about the Markforged ONYX

How heat-resistant is the Markforged ONYX?

Onyx has a heat resistance of 145°C (293°F)

How strong is onyx?

Onyx has a flexural strength of 81 MPa (11.7 ksi). For more information on Onyx material properties, see Data sheet.

What is the difference between short and continuous carbon fibers?

Markforged Onyx filament contains short carbon fibers that give the material high rigidity and strength. Continuous carbon fibers are a reinforcing fiber that can be individually inserted into the component in long strands, allowing for the production of mechanically resilient components. Composite components are many times stronger and stiffer than pure Onyx components. Markforged ONYX components reinforced with continuous carbon fibers have strengths that exceed those of aluminum. For more information, see this article.

Does Markforged ONYX cause warping or swelling of the printed part when used in conjunction with coolant?

No, we cannot detect any distortion of the component when using coolant or other fluids.

Learn more about the applications with the desktop series!

How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed some information sources that will help you get the answers you need.

Would you like a demo, have questions or need a quote for a Markforged X-Series printer?

Contact us now!

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.