Kevlar® continuous fiber

What is Kevlar® continuous fiber?

Kevlar® is a tough, lightweight material that can bend further than any other fiber, making it ideal for 3D printing.

When should you print with Kevlar® continuous fiber?

Kevlar® is best used in parts that are subject to impact. Its low density and high durability make it a great option for applications that require a lot of movement or involve production parts.

Reducing changeover times and increasing plant throughput with Markforged technology

There are now 53 unique printed parts on the pad handling machine, including fuse covers, end effector laser sensor mounts, mechanism covers, bump stops, motor mounts, and more.

“People were blown away by the overall quality; they never thought they would see printed parts applied to machines that would actually be used in a production environment.”

Phil M., Senior Mechanical Designer

Request a DEMO component now!

See for yourself how strong the continuous fibers are.

FAQ

What is Kevlar® continuous fiber?

Kevlar® is a synthetic fiber developed and produced by DuPont. Known for its light weight and toughness, it is traditionally used in products such as tires, sails, ropes, and protective gear. Kevlar® is an excellent material for 3D printing.

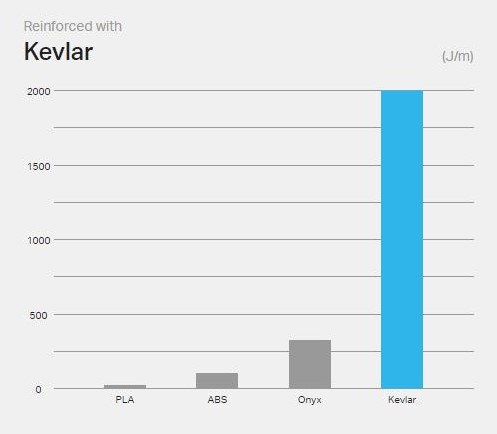

How strong is Kevlar® continuous fiber?

For a full explanation of the material properties of 3D printed Kevlar, please see our composites datasheet.

How much does Kevlar® continuous fiber cost?

A 50cc spool costs €106.90 including VAT and a 150cc spool costs €319.90 including VAT.

Learn more about the applications with the MarkTwo!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Would you like a demo, have questions or need a quote for a Markforged X-Series printer?

Contact us now!

![]() Mark3D GmbH

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396-00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.