The company

BEULCO GmbH & Co. KG specializes in the manufacture and processing of high-quality products for the water supply industry.

The multi-award-winning family business based in Attendorn has been using additively manufactured parallel grippers and suction pads for workpiece handling with robots since January 2020 and has already saved €200,000.

Project goals

High number of variants and tool costs

BEULCO GmbH & Co. KG uses parallel grippers and suction pads for workpiece handling with robots and was faced with several challenges at the same time.

During metalworking, the workpieces have to go through two steps. In the first step, the components must be deburred and then machined in the second step. In both process steps, the systems are loaded by robots.

All pressed workpieces have individual contours and there are also over 300 different versions. In addition, high tool costs led to the search for a more cost-effective alternative to the existing metal grippers.

The aim was to manufacture cost-efficient, customized robot grippers suitable for industrial use.

At a glance

Solution

Additive manufacturing with composite materials

At EMO 2019 in Hanover, Lutz Schopen, Head of Technology, discovered the technology of industrial Markforged 3D printers.

The possibility of reinforcing the components with the continuous carbon fiber during the printing process was the main criterion for him to invest. He quickly realized that this technology could become a game changer for BEULCO in the field of gripper technology. He hoped that it would drastically reduce costs in the area of end-of-arm tooling.

Steep learning curve after initial skepticism in the team

At first, the team was skeptical about the new technology. "If it's not made of metal, it can't last." - was the team's response.

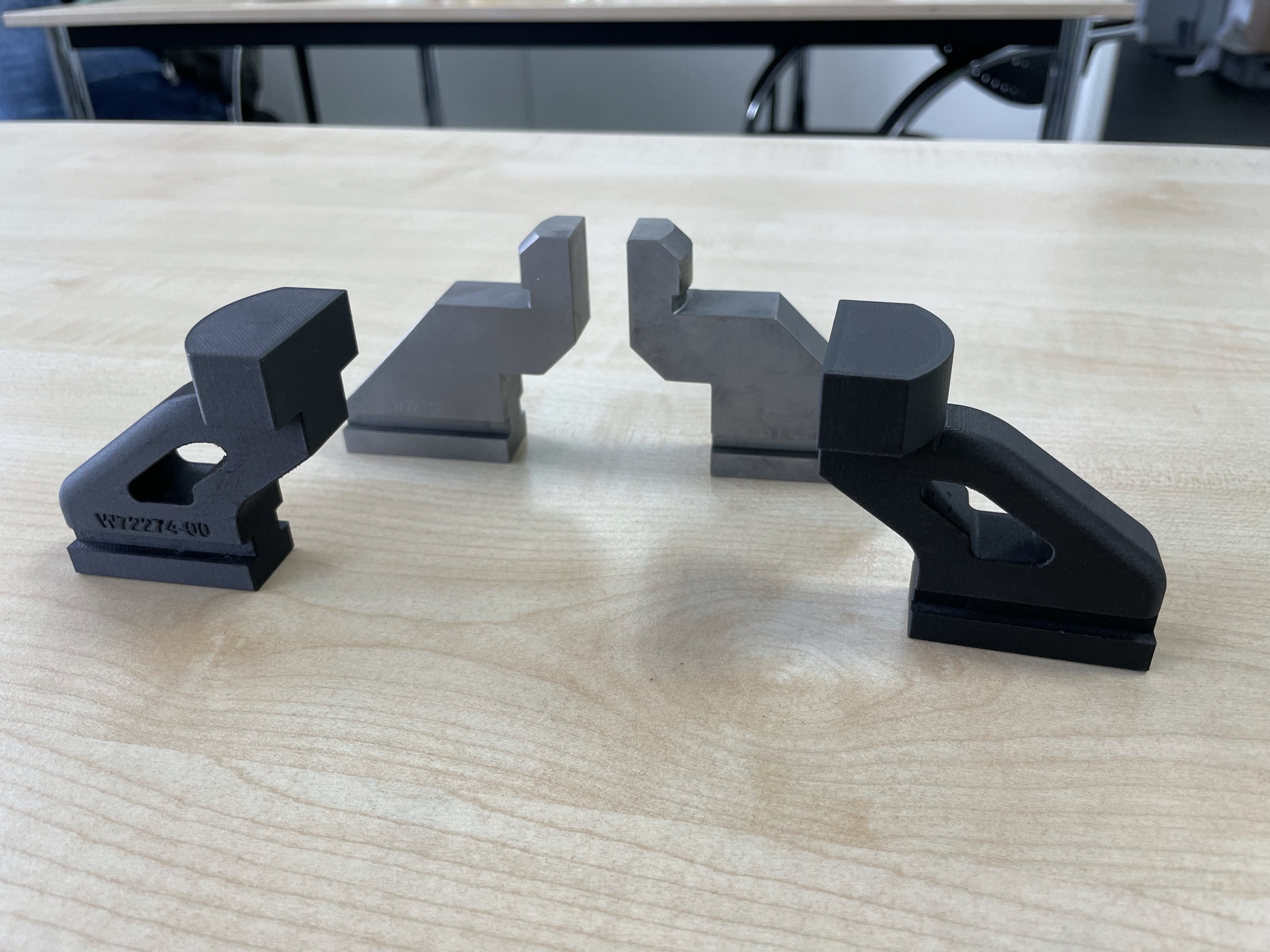

A first sample component from Mark3D GmbH was quickly able to impress with the results of the first tests on its own test bench. Initial wear tests were carried out on this test bench and experience was gained. Among other things, a separate concept for connecting the gripper to the robot was developed after a rethink in the design had taken place.

The grippers have already been optimized for additive manufacturing during the design phase.

"In 1 1/2 years, the 3D printer ran for 6500 hours. That corresponds to a workload of around 70 % in three-shift operation. We are delighted with the hardware. The software is sufficient for "normal" applications. Service and support from Mark3D have always been exemplary!"

- Lutz Schopen, Technical Management, BEULCO GmbH & Co. KG

Request a DEMO component now!

See for yourself how strong the components are.

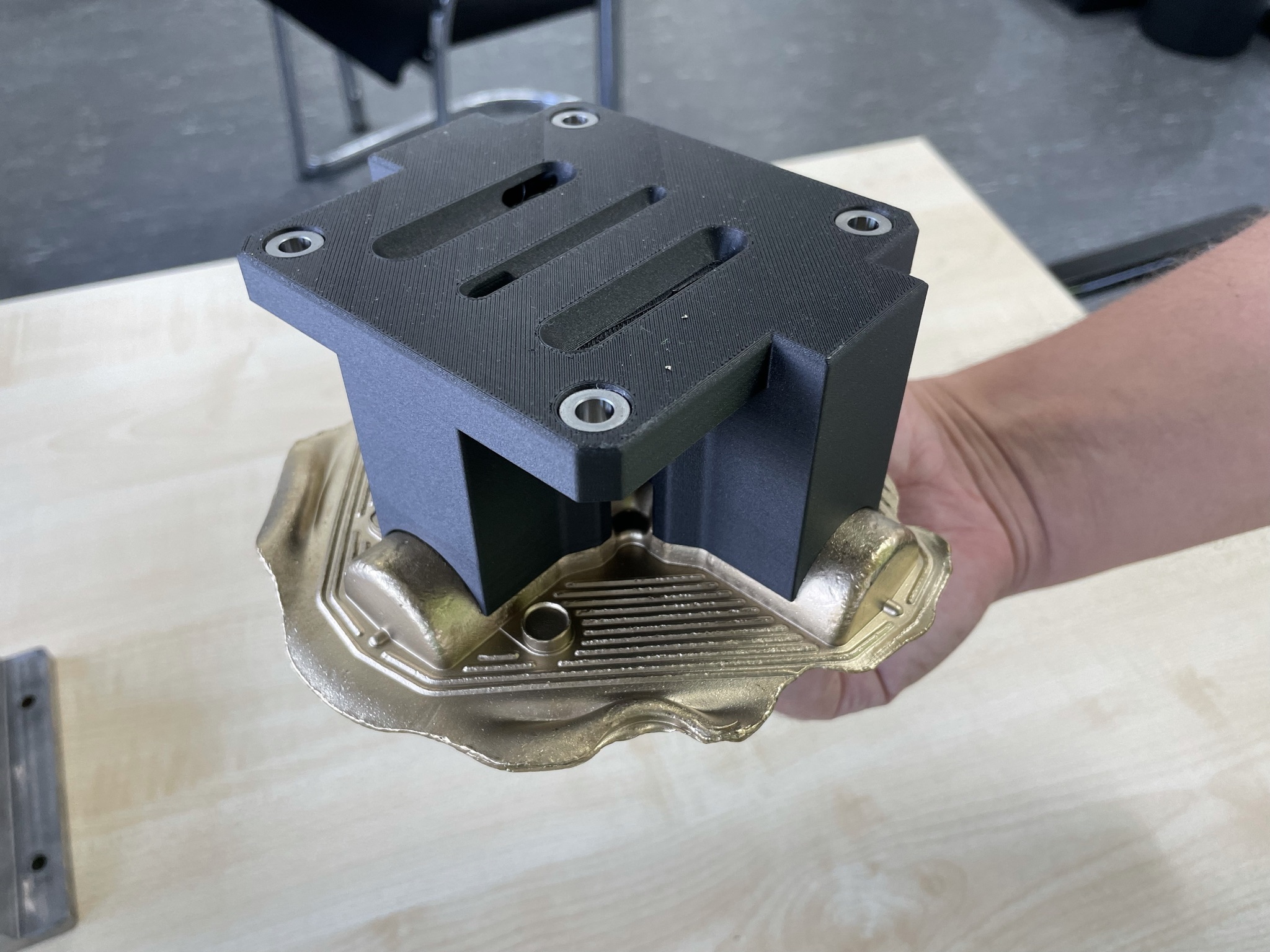

Implementation

In the course of this, the connection of the grippers was changed from a force fit to a form fit. The groove of the gripper is pushed into a C-slot of the robot, clamped with a plate and screwed in place. This eliminated the weak points of the attachment. Thanks to the modular design, it is now possible to use the grippers in both processing steps on the robot systems.

Additive manufactured grippers exceed expectations:

No detectable wear on suction pads!

"Not a gimmick, but real means of production at BEULCO GmbH & Co. KG!", emphasizes Lutz Schopen. The new additively manufactured grippers meet the requirements in 99 % of the applications. Some of the suction pads have already been used for over 200,000 cycles and show no measurable signs of wear.

wear. The high loads resulting from fast movements do not affect the durability, nor do the cooling lubricants with which the components come into contact.

Furthermore, procurement times (external procurement) have been significantly reduced from 4-6 weeks to 1-2 days, ideally to 24 hours. Added to this are huge savings. A total of €200,000 has already been saved on over 330 pairs of printed grippers and suction pads.

The Mark Two 3D printer thus paid for itself in less than two months!

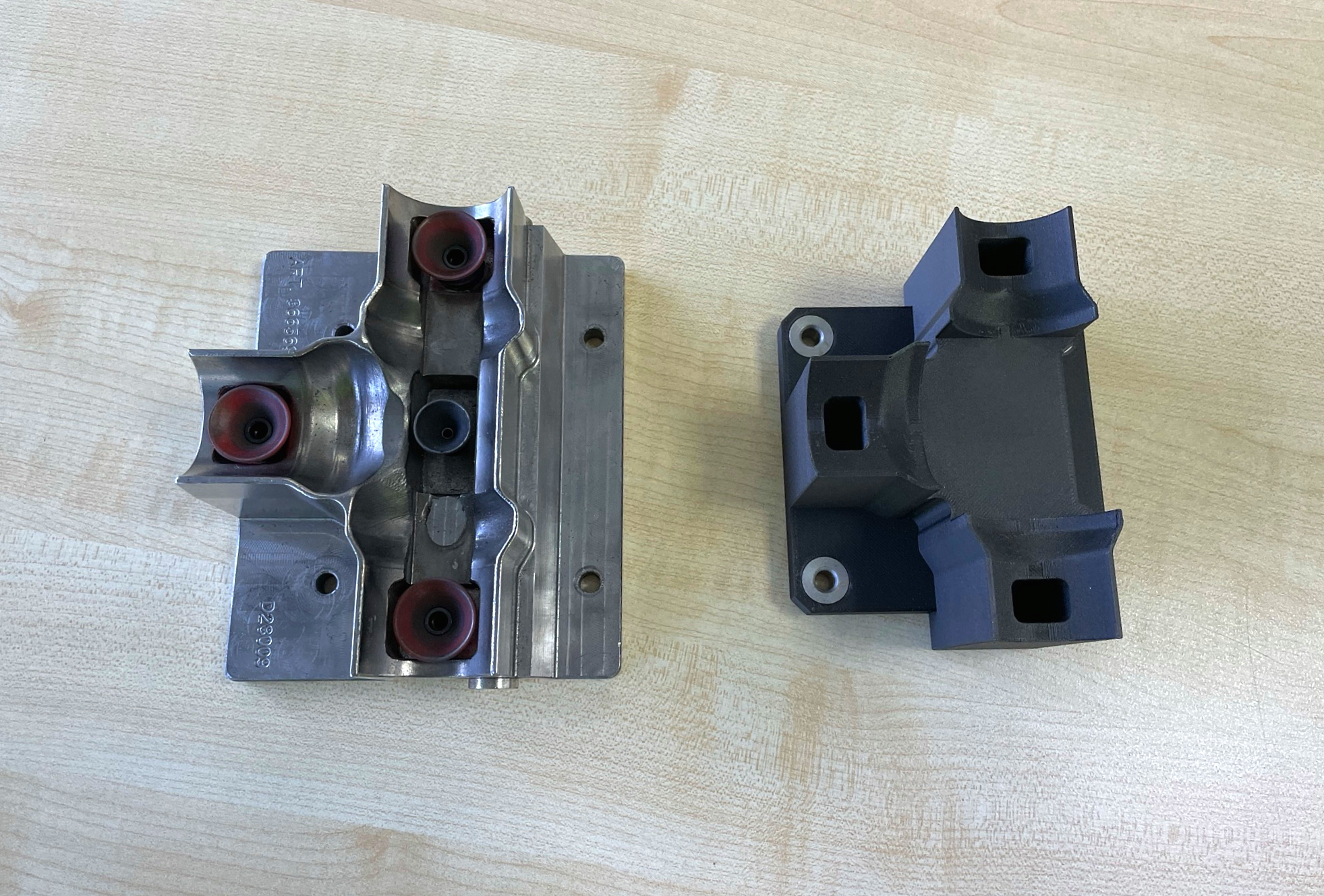

Suction pads in detail

Milled steel

Weight: 3194 g

Costs: 1.145,00 €

Delivery time: 4-6 weeks

Additive manufactured

Weight: 189g

Cost: 100 €

Delivery time: 24 hours

The future

Additively manufactured clamping jaws

Replacement grippers and grippers in new designs are still planned for the future. There is still a regular need for them.

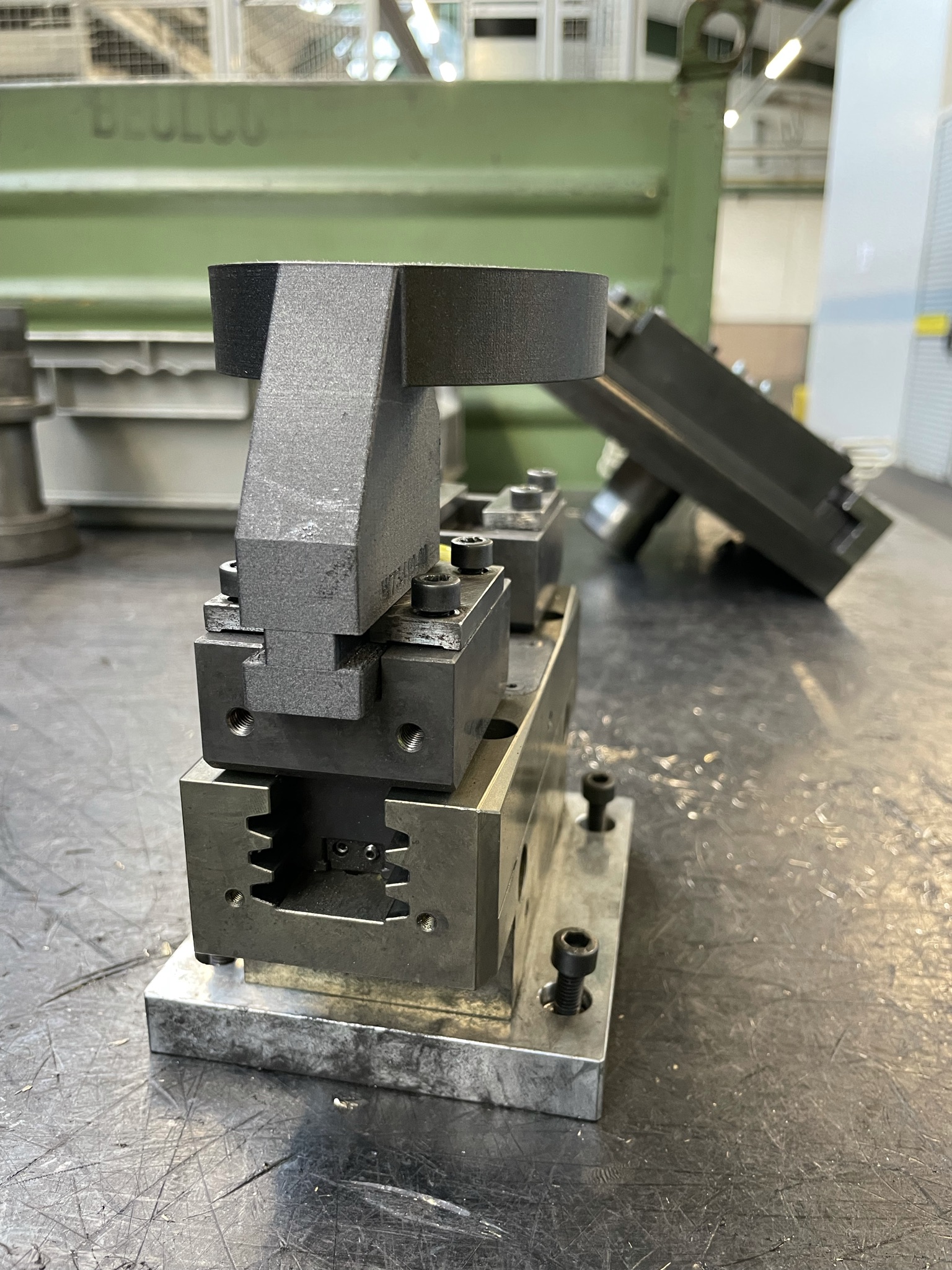

BEULCO GmbH & Co. KG sees additively manufactured clamping fixture jaws for the series production of workpieces on automatic lathes and machining centers as another field of application. Here, BEULCO faces challenges such as strong forces and high heat generation. A solution is being worked on together with Mark3D GmbH.

Learn more about the applications with the MarkTwo!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Would you like a demo, have questions or need a quote for a Markforged 3D printer?

Contact us now!

![]() Mark3D GmbH

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.