The company

MMB Maschinen, Montage & Betriebsmitteltechnik GmbH is breaking new ground in the field of additive manufacturing. Additively manufactured components are a common thread throughout the entire company. Their constant commitment to innovation and risk-taking has made them what they are today: a dynamic company with 40 employees and numerous renowned customers in almost all industries.

Project goals

Manufacturing of unique components

Almost every component is unique – due to the high level of customization, MMB designers face new challenges every day.

From development and initial designs to production and delivery, special machines are customized and designed to meet customer requirements. These include joining machines, machines for hood hinges, and door locks. A focus is also placed on operating equipment such as clamps, brackets, and clamping devices.

Until now, these components were manufactured using conventional methods (machining, casting, welding, etc.). However, low volumes, long lead times, complex geometries, and high costs limited this process.

The aim was to produce these individual components and small series more cost-effectively and to achieve significantly greater flexibility in design.

At a glance

Solution

Skeptics are quickly convinced

Components manufactured using new technologies must also be robust, ready for immediate use, and able to withstand endurance testing. Carsten Blucha has been working with conventional manufacturing methods for decades and appreciates their quality. At an event in Solingen, he discovered the stability and surface accuracy of Markforged 3D printers, something he had never experienced before in the field of additive manufacturing. Despite initial skepticism, he was impressed by the additively manufactured components. He was also able to convince his management with a customized sample component.

The beginning of a success story

Together with his colleague René Arndt, Carsten Blucha has been producing finished components and equipment around the clock on two Markforged 3D printers.

The Mark Two has been running for about four years, logging over 32,500 hours (7,210 hours per year)! The 3D printers produce complex machine components 24/7, overnight!

Customers were initially surprised by the additively manufactured components. However, the stability, strength, and design freedom quickly convinced them.

"You have to dare to break new ground. Many people stick with what has always worked well. But in doing so, they miss out on many new opportunities!"

– Carsten Blucha, 3D Application Engineer, MMB GmbH

Request a DEMO component now!

See for yourself how strong the components are.

Implementation

Manufacture complex machine components easily and overnight

The Markforged 3D printers impressed with their high-quality surface finish, strength, and speed, as well as the easy removal of the support material. This truly is plug & play at an industrial level.

The additive manufacturing fleet includes additional 3D printers for initial design checks and testing. They also have an SLM system for the additive manufacturing of complex metal components from tool steel. The print farm, comprising a total of six 3D printers, is clearly dominated in terms of utilization by the two Markforged machines, Mark Two and Basic One.

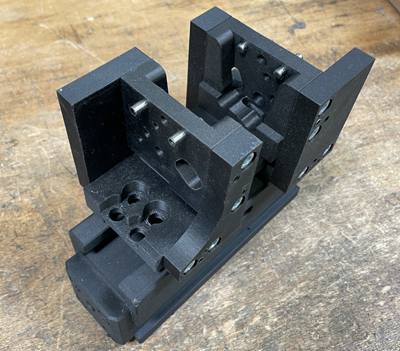

In addition to real functional prototypes, the most common applications now include component holders such as complex sensor mounts, component feeding systems or workpiece carriers, which are manufactured in small quantities and with complex geometries and thus improve the processes within the special machines or even make them possible in the first place.

Today, 3D printing with Markforged is a standard feature in almost every system. Thanks to additive manufacturing, production can now be carried out much faster and more independently.

Even after a machine has been delivered, we can respond quickly to customer component changes with appropriate fixtures, grippers, etc. This increases customer satisfaction and loyalty.

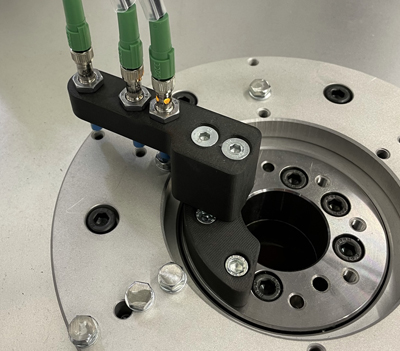

Test terminals

Test clamps are used to check the flow rate of a pipe using a sensor. These were originally made of metal, but even very light metals were too heavy to handle. Printed from Onyx, the test clamps are much lighter and significantly more ergonomic for 8-hour handling. The new geometry cannot be manufactured using conventional manufacturing methods.

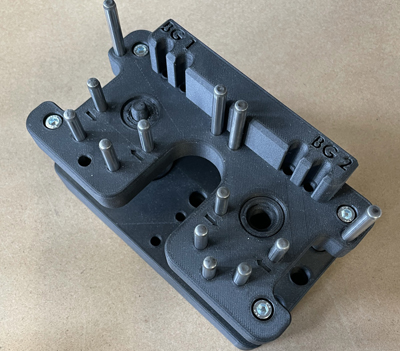

“Poka-Yoke” masks

Custom components are ideal for additive manufacturing. These component-specific fixtures help ensure the correct positioning of the component to be machined. Holes for the pins in the fixture were drilled and then secured with adhesive.

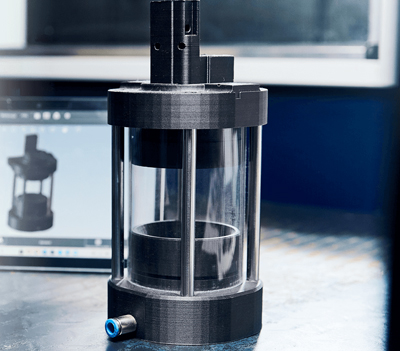

vibratory conveyor

MMB has brought particular expertise to a fully 3D-printed vibratory conveyor, which is used for separating and aligning small components. MMB often requires pre-sorting small components. This custom 3D-printed vibratory conveyor ensures that the parts are transported to further processing in the correct alignment. Misaligned parts are conveyed back into the bowl using air pressure. The bowl consists of two individually printed parts.

Additive manufacturing can save several days of production time and 50% of manufacturing costs for many components.

More and more, individual components could be manufactured overnight using 3D printers in complex machines. Initial skepticism turned into great enthusiasm for the new manufacturing technology, which delivers new added value to the company every day.

"Markforged offers a very good all-in-one package for producing professional components quickly and easily. In fact, you get ready-to-use components overnight!"

– René Arndt, 3D application technician, MMB GmbH

The future

Expansion of the print farm

Additive manufacturing will continue to be an integral part of MMB GmbH's future. The ability to design components in completely new ways offers MMB – and its customers – completely new possibilities.

With the savings already achieved, the printer park has been expanded and will continue to be expanded in the future as the focus shifts to contract manufacturing.

Novel materials such as Onyx ESD and copper could also complement the portfolio. The success story of additive manufacturing will certainly continue at MMB in the future.

Learn more about the applications with the MarkTwo!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Would you like a demo, have questions or need a quote for a Markforged 3D printer?

Contact us now!

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.