The company

Amari Austria develops and manufactures high-quality aluminum solutions for construction, industry, and mobility. Its headquarters in St. Johann, Autria is the central competence center for development, production, and sales.

With additional branches in Hungary and Romania, the company not only serves the European market, but also supplies customers worldwide.

The portfolio ranges from facade and window constructions to flood protection systems and components for special vehicles and rail transport.

Why it was time to introduce a new manufacturing process

Until 2015, new products at Amari were developed using traditional methods: based on aluminum profiles that were milled, drilled, or welded. Fixtures and prototypes were also manufactured mechanically from metal and often had to be laboriously adjusted.

In the course of this process, it became clear that there was growing potential for optimization, particularly in the following areas: Amari klassisch entwickelt: auf Basis von Aluminiumprofilen, die gefräst, gebohrt oder verschweißt wurden. Auch Vorrichtungen und Prototypen wurden aus Metall mechanisch gefertigt und mussten oft aufwendig angepasst werden.

Im Verlauf wurde deutlich, dass insbesondere in folgenden Bereichen ein wachsendes Optimierungspotenzial besteht:

That is why experiments with a simple 3D printer were first made in 2015 – originally primarily as an internal test object. However, it quickly became apparent that additive manufacturing can do more than just produce visual aids – it offers real advantages in development, production, and cost-effectiveness.

How industrial 3D printing perfectly complements and optimizes existing manufacturing processes

The goal: to shorten development times, reduce tooling costs, and make manufacturing significantly more flexible. The new technology was introduced centrally and used across departments—from design and manufacturing to sales. The necessary rethinking was also actively promoted: Sales acquired basic knowledge, trainees designed the first components, and management anchored additive manufacturing early on as a strategic topic for the future.

strategisches Zukunftsthema.

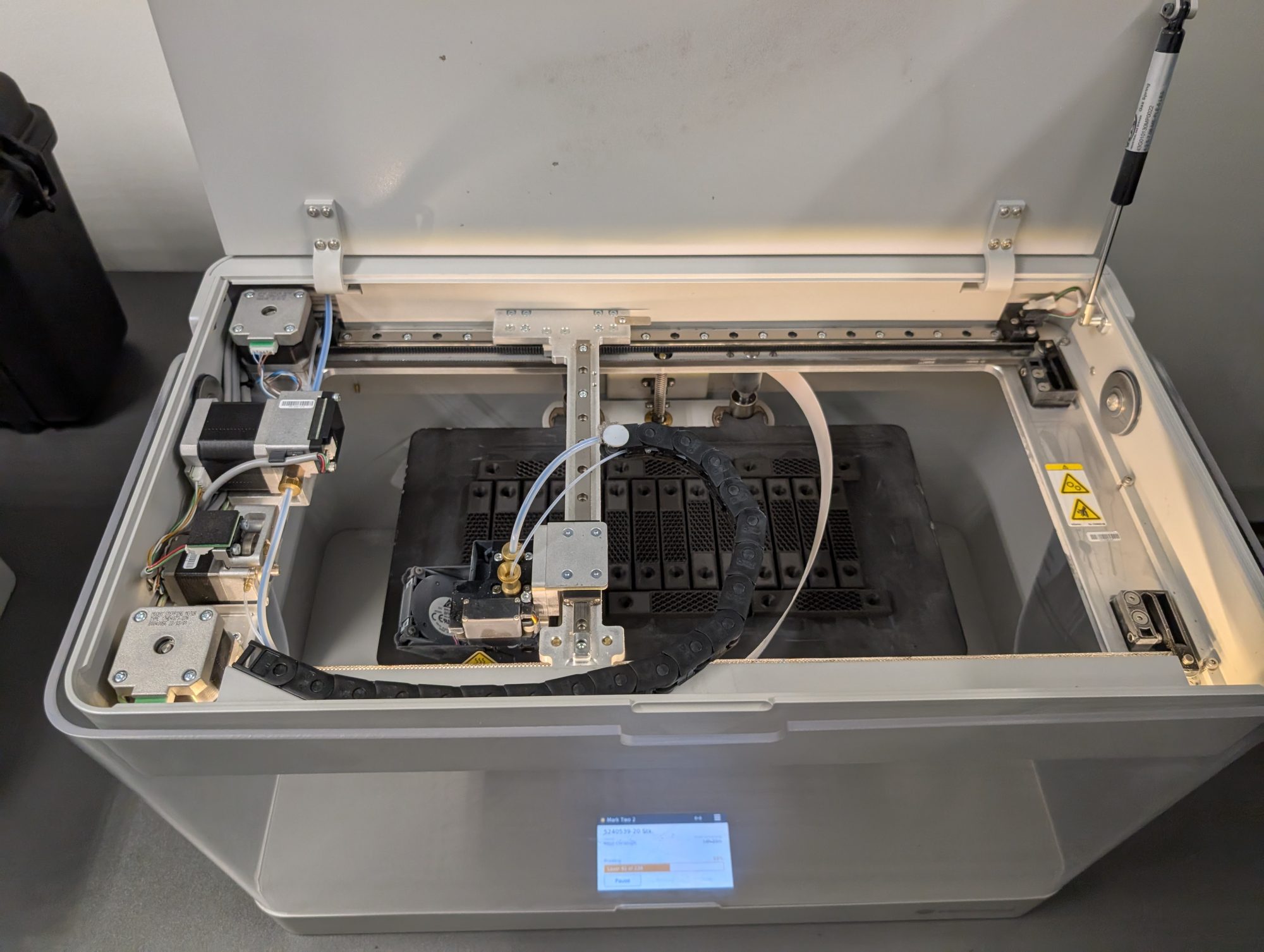

„Unser Ziel war nie, jemanden zu ersetzen. Wir wollten neue Möglichkeiten schaffen – schneller, wirtschaftlicher und kreativer.“ sagt Christoph Hölzl, Leiter Additive Fertigung. Heute ist der industrielle 3D-Druck fester Bestandteil der Entwicklungsprozesse und der Kleinserienproduktion. Seit 2023 nutzt Amari zusätzlich den FX20 von Markforged und erweitert die Kapazitäten damit deutlich Die Auslastung liegt bei bis zu 90 %, teils im 24/7-Betrieb. „Die Maschine arbeitet, während ich nach Hause fahre – das ist wie ein Kollege in der Nachtschicht.“

In 2017, Amari began searching specifically for an industrial-grade 3D printing solution. After testing sample parts and visiting Formnext, a Markforged machine was purchased.

The decisive factors were

• the high print quality

• the speed

• and the ability to produce stable components with continuous fiber reinforcement—even for demanding applications.

“The combination of print quality and speed that

we achieve with the FX20 is impressive.”

– Christoph Hölzl, Innovation & Additive Manufacturing

Technology meets culture – Change at Amari

The introduction of additive manufacturing at Amari was much more than a technical decision; it also changed structures and mindsets within the company. From the outset, industrial 3D printing was not assigned to a single department, but established as a cross-functional competence. Development, production, sales, and other teams use the technology together, contributing their specific requirements and ideas.

To embed this new way of working in everyday life, Amari focuses on targeted training and qualification:

• Product managers learn about the possible applications of the technology and components.

• Internal sales teams can provide targeted support to customers in identifying suitable applications.

• Trainees are introduced to additive thinking at an early stage—from the idea to the production-ready component.

The goal: to establish additive manufacturing not as an isolated solution, but as an integral part of a modern, flexible, and collaborative way of working. Openness to new technologies is firmly anchored in Amari's corporate culture – supported by management with a clear vision for the future and employees who actively shape change.

Additive manufacturing: A technology for all areas

Today, industrial 3D printing is an integral part of almost all business areas at Amari—from development and manufacturing to small-batch production.

The technology is used particularly intensively in the fields of architecture, mechanical engineering, and flood protection. Here, functional parts such as clamping systems, flood protection clips, and mechanical engineering devices are created—efficiently, precisely, and in line with requirements.

Classic fixtures and prototypes are also increasingly being replaced. Whether tool changes, identification systems, clamping systems, or test setups – the technology enables fast, economical solutions without long lead times.

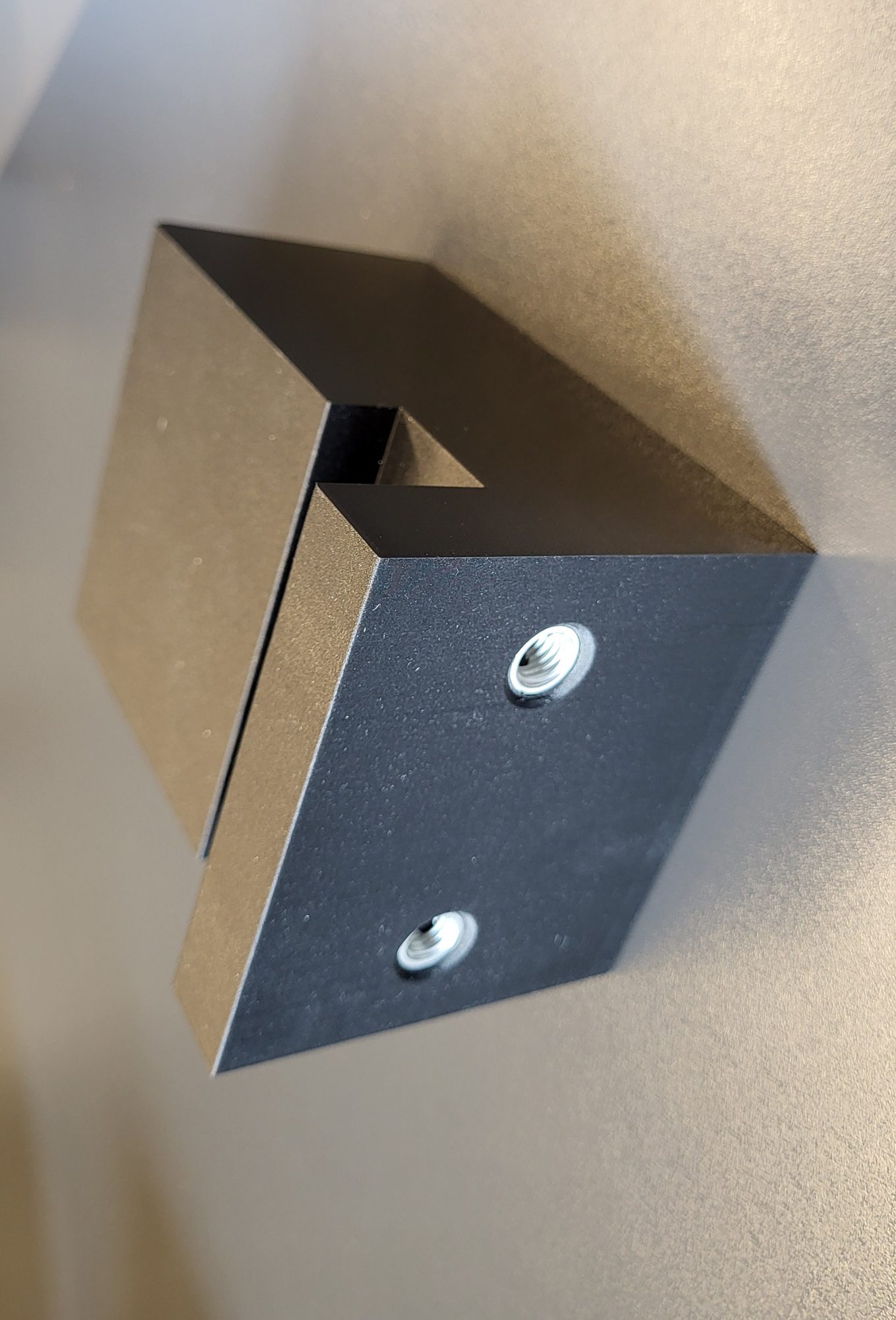

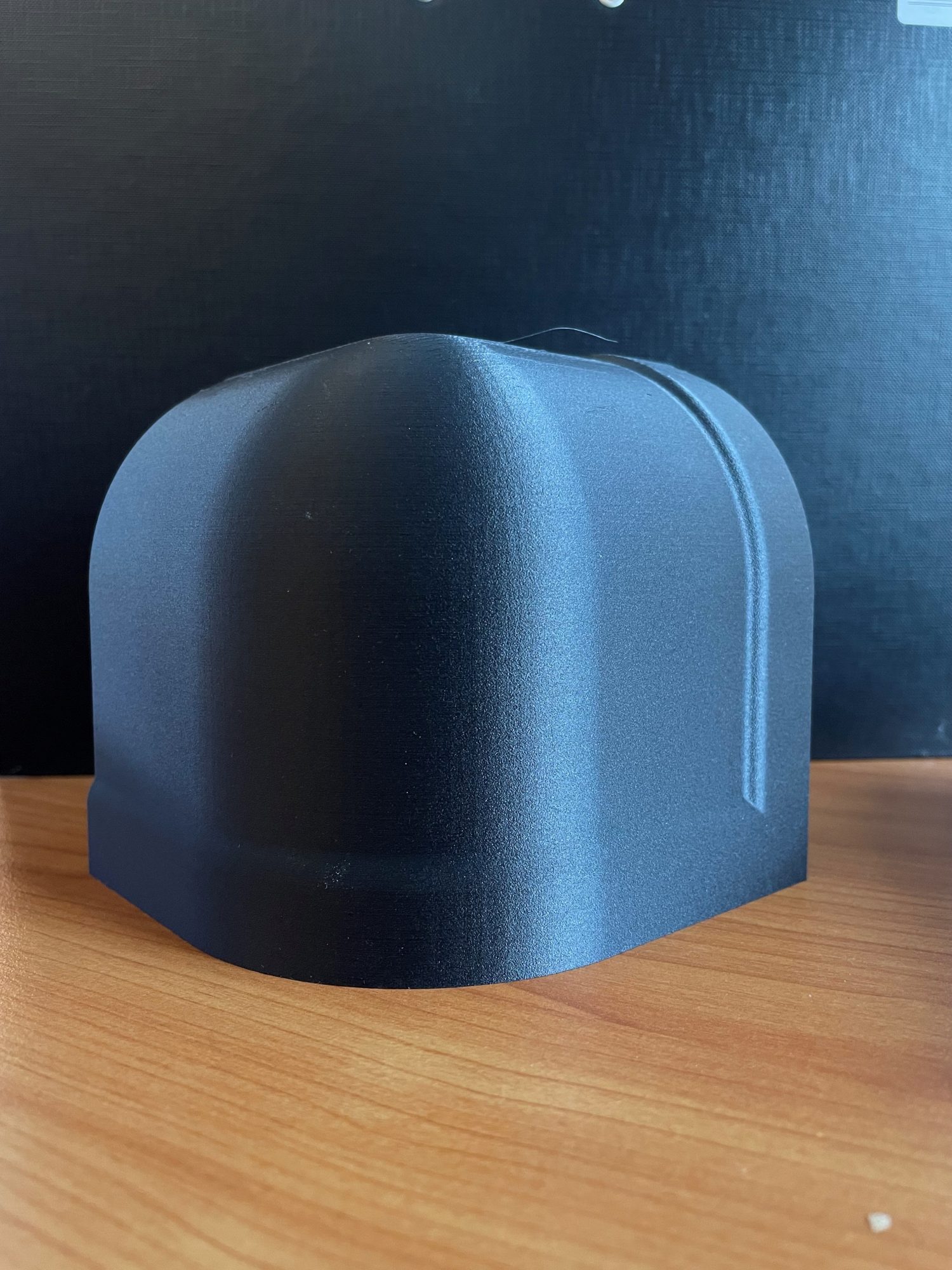

In commercial vehicle technology, individual components such as special housings, adapters, or camera mounts are now being produced that would conventionally only be possible with great effort.

In addition to internal projects, external demand is also growing. Customers from the medical technology, mechanical engineering, and supply logistics sectors are increasingly relying on additively manufactured components – individually produced, quickly available, and economically attractive.

Besonders intensiv genutzt wird die Technologie in den Bereichen Architektur, Maschinenbau und Hochwasserschutz. Hier entstehen Funktionsteile wie Spannsysteme, Hochwasserschutz-Clips und Maschinenbauvorrichtungen – effizient, präzise und bedarfsgerecht.

Auch klassische Vorrichtungen und Prototypen werden zunehmend ersetzt. Ob Werkzeugwechsel, Identifikationssystem, Spannsysteme oder Prüfaufbauten – die Technologie ermöglicht schnelle, wirtschaftliche Lösungen ohne lange Vorlaufzeiten.

In der Nutzfahrzeugtechnik entstehen heute individuelle Bauteile wie Sondergehäuse, Adapter oder Kamera-Halterungen, die konventionell nur mit hohem Aufwand umsetzbar wären.

Neben internen Projekten wächst auch die externe Nachfrage. Kunden aus der Medizintechnik, dem Maschinenbau und der Versorgungslogistik setzen verstärkt auf additiv gefertigte Bauteile – individuell gefertigt, schnell verfügbar und wirtschaftlich attraktiv.

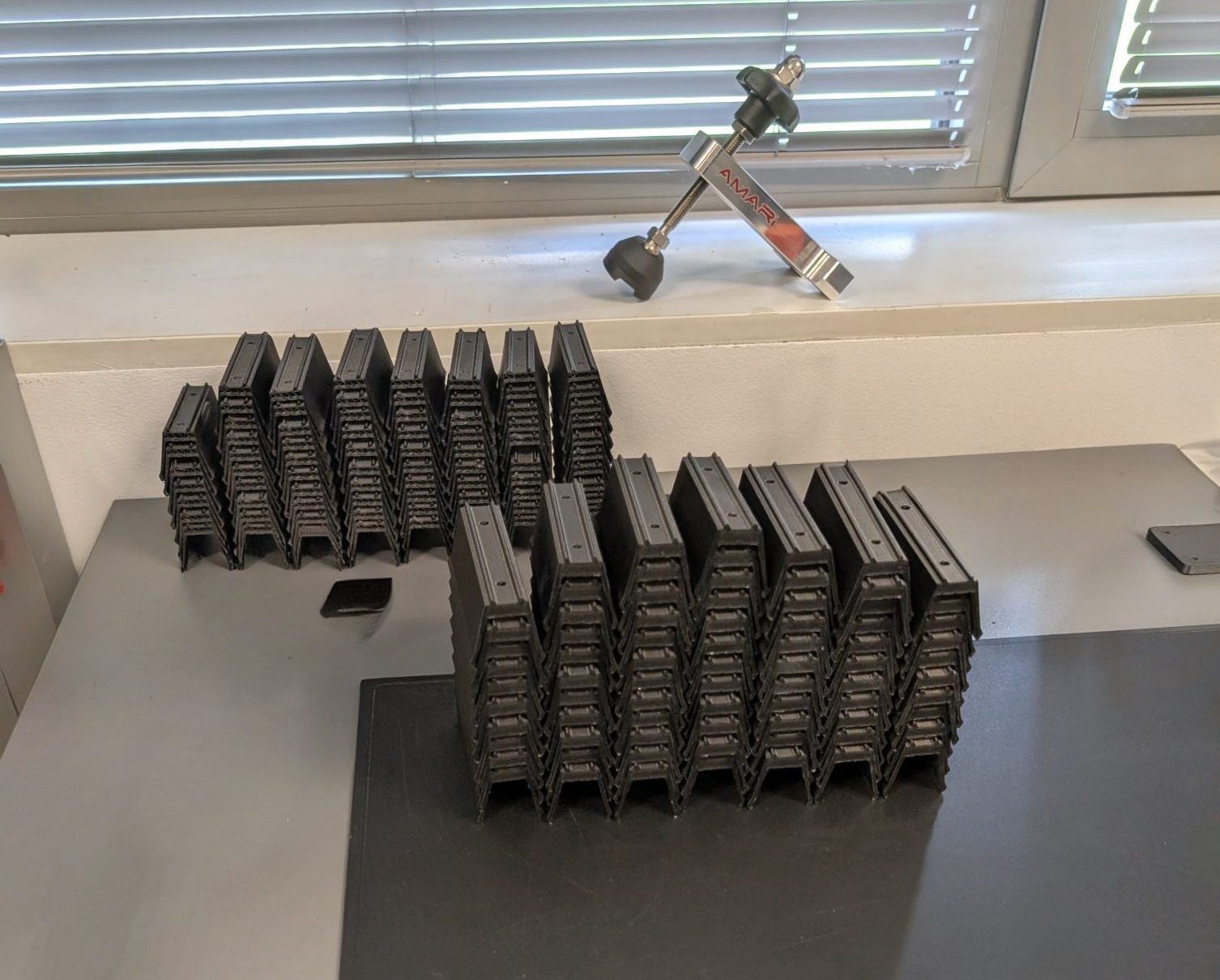

Case study: Flood protection clips

A clip element that would previously have been manufactured using an aluminum tool is now produced directly using additive manufacturing.

Previously:

• Tooling costs: €5,000–10,000

• Plus material, storage, and cutting

Today:

• Additively manufactured for only €7.50 per piece

• For 1,000 pieces: total cost approx.

€7,500 – and that's without any investment in tools

Advantages of industrial 3D printing at Amari

Acceptance and enthusiasm

Feedback from the team and the market

The introduction of additive manufacturing at Amari was initially met with reluctance, particularly in mechanical engineering and machining.

There were concerns above all regarding stability, dimensional accuracy, and possible effects on existing processes.

Doch die Praxis überzeugte: Funktionale Vorrichtungen, deutlich kürzere Entwicklungszeiten und spürbare Kosteneinsparungen bewiesen schnell das Potenzial der neuen Technologie.

The decisive factor was that industrial 3D printing was introduced not as a replacement, but as a useful addition—with the clear goal of working faster, more flexibly, and in a more customer-oriented manner.

Today, additive manufacturing is firmly established at Amari – in development, production, and sales.

Trainees also play an active role and implement their own projects – in a practical and future-oriented manner.

Customers enjoy clear advantages: Amari receives positive feedback, especially for customized solutions, fast availability, and complex geometries.

Many applications would not have been technically or economically possible with conventional methods.

Outlook: The future of additive manufacturing at Amari

In recent years, additive manufacturing at Amari has evolved from a supporting tool to an indispensable part of development and production.

The next big step is already on the horizon: Additive manufacturing is to be organized as an independent business unit in the future—with clear structures, its own identity, and defined responsibilities.

The goal is ambitious: additive manufacturing will not only support other departments, but will also independently enable new products, innovative solutions, and forward-looking business models.

At the same time, it will remain a connecting element that creates interfaces between development, production, sales, and external partners.

Planned focal points include:

• Surface finishing to improve quality

• Use of modern scanning technologies for reverse engineering

• Expansion of small-batch production and establishment of a standardized component catalog

• Expansion of production capacities, for example through additional machines

• Entry into metal 3D printing to further expand the range of applications

Would you like a live demo, have questions or need a quote for a Markforged 3D printer?

Contact us now!

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers