"The components made from the base material Onyx have proven to be highly wear-resistant and fracture-proof, even under extreme loads. This means they can also be used safely in sandblasting applications. Compared to milled components, a weight reduction of over 601 t/3t was achieved. The lead time for production is now just a few hours." – Marc Krause of BMF GmbH

The Smart Surface Control technology, specially developed by Chemnitz-based BMF GmbH, requires a multitude of different components, some of which require complex manufacturing processes. This previously required a long production lead time and complex warehousing.

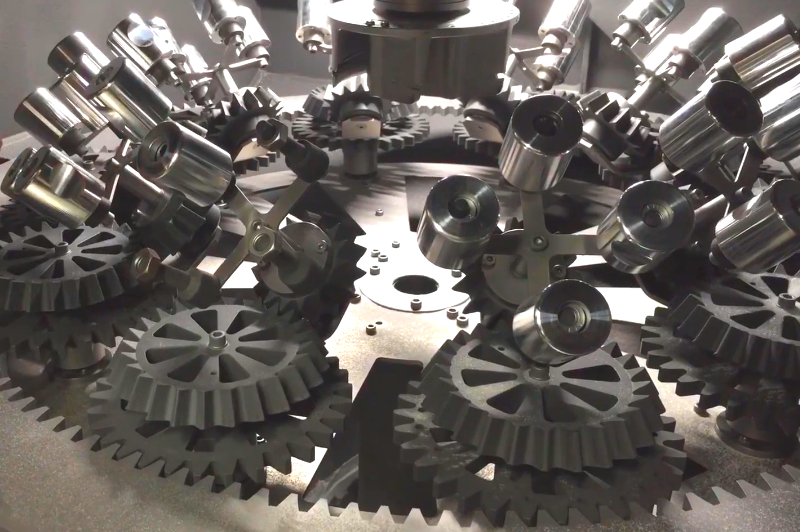

A variety of different parts for the Twister and Tornado are now manufactured on several Markforged 3D printers, as needed.

Request a DEMO component now!

See for yourself how strong the components are.

Leave A Comment