Dixon Valve & Coupling uses the MarkTwo to print clamping jaws for industrial robots in production.

| Cost | Time | |

| CNC manufacturing service | $290,35 | 72 hours + shipping |

| Markforged 3D printed | $9,06 | 9 hours, 20 minutes |

Everything under control

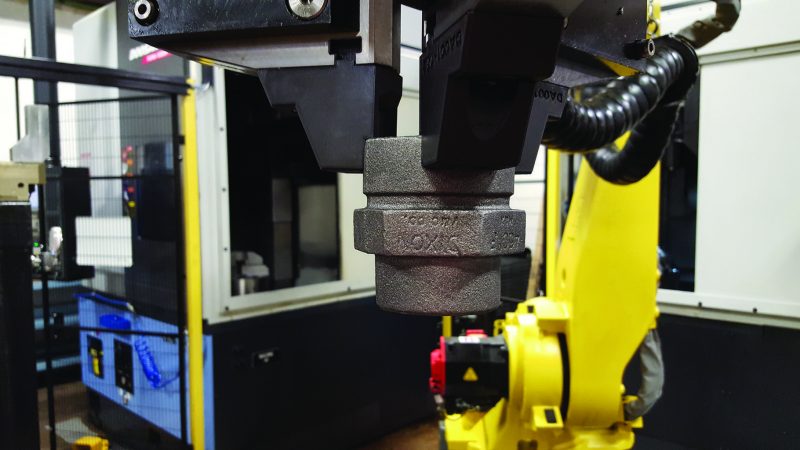

The arm of a FANUS industrial robot swings gracefully from one machine to another. Its precision-fitted clamping jaws securely clamp a pipe fitting. At Dixon Valve's manufacturing facility in Chestertown, Maryland (USA), these robots are typically used to transport parts. Strength, safety, and chemical resistance are key components in Dixon Valve's efficient work environment. That's why each robot arm is equipped with a set of Onyx clamping jaws, manufactured using the MarkTwo 3D printer.

A gripper with two clamping jaws fits onto a pipe fitting.

Manufacturing engineer Max de Arriz explains that a large robotic arm transports parts between two vertical turning centers. With thousands of different valves, fittings, and measuring devices manufactured here, each product line requires specialized equipment, such as special tools, fixtures, and clamping jaws.

Within reach

Before Dixon Valve 3D printed its clamping jaws, they were custom-made by machine. Some gripping tools had to be manufactured externally. This was always expected to be time-consuming and costly. The parts must be precise, stable, and chemically and wear-resistant. 3D-printed components meet all of these criteria.

Dixon Valves pipe fittings aligned with the 3D printed bracket.

Immediately after unpacking, the Markforged 3D printer was tested and the first parts were printed. A robot arm was equipped with new tools within 24 hours. Embedded reinforcing fibers gave the 3D-printed parts greater stability.

"Onyx is one of my favorite materials because it combines a very strong composite with the chemical resistance of nylon. The stability and chemical resistance are just right for us." JR Everett

hand in hand

A robotic arm with 3D-printed grippers is at work in Dixon Valve's manufacturing facility. A new set of clamping jaws can be manufactured in less than a day with the MarkTwo.

As a powerful new tool, the MarkTwo enables new production solutions with unprecedented time and cost savings. The way things work at Dixon Valve is no longer the same. Everett explains that processes and plans have been changed to accommodate this "groundbreaking product." By incorporating the 3D printer into the company's workflow, Dixon Valve has been able to continue to grow and improve. Being able to produce strong, stable, high-quality parts at low cost is Dixon's key to success. Everett believes that with the 3D printer, anything imaginable is possible.

“If you can imagine it, you can create it!”

Hinterlasse einen Kommentar