“When we started supplying smaller quantities of special tools to customers, this became a problem,” explains Alan Pearce, Head of PCD Production at Guhring UK.

Every piece of special tooling that Guhring produces must first be approved by the customer. Depending on the size and complexity of the component, special tools can take up to eight weeks to develop, test, and manufacture in-house. Work on the tool cannot begin until the design is approved. Smaller manufacturers with lower volumes cannot justify the cost or lead time for special tools.

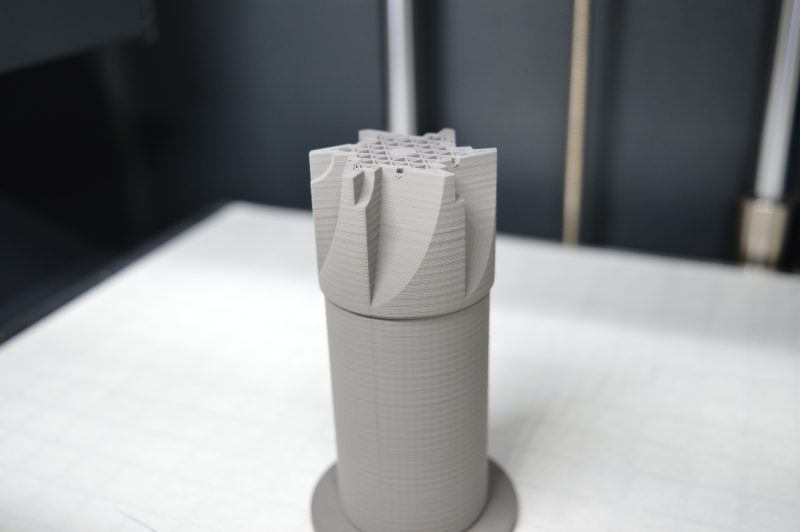

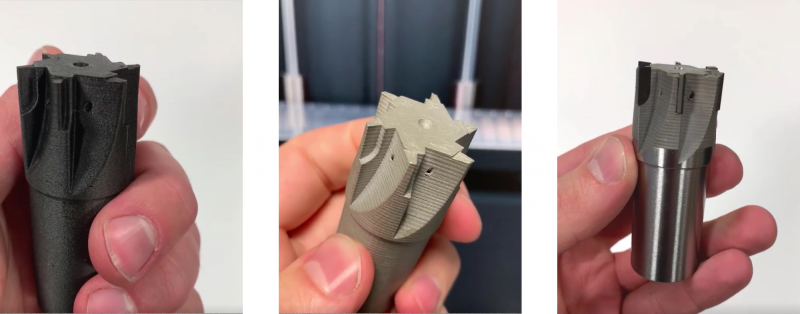

Thanks to the Markforged 3D printers, Gühring can present a 3D-printed Onyx prototype at the first customer meeting just a few days later. Based on this, the final cutting tool is then printed on the Markforged Metal X 3D printer using H13 tool steel.

Additive manufacturing in a subtractive world

The Guhring Group is a leading global manufacturer of precision cutting tools and related tools for the mechanical engineering and manufacturing industries. With more than 8,000 employees worldwide and a product range of 1,620 products (in 44,000 sizes), Guhring is recognized as a leader in its field.

Leave A Comment