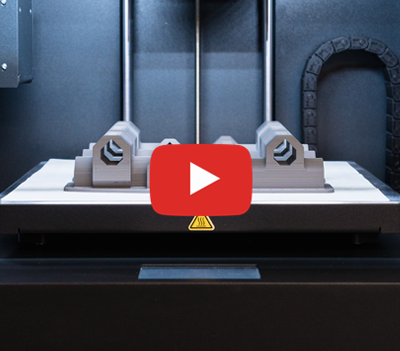

“3D printing pure copper with the Markforged Metal X system is faster and more cost-effective than purchasing complex machined components.”

A German automobile manufacturer operating worldwide prints customized welding electrodes for spot welding made of pure copper!

According to a maintenance manager at the company, component costs were reduced by 50% and lead times were reduced from 14 weeks to 3 days! Additionally, the honeycomb structure inside the component allows for a massive weight reduction!

Pure copper with very high electrical and thermal conductivities can now be printed layer by layer using the classic filament printing process.

What are the advantages of copper 3D printing?

✅ Very high conductivities

✅ Quick first prototypes

✅ Significant design freedom

What would you print in copper first? Write it in the comments ⤵

Request a DEMO component now!

See for yourself how strong the components are.

Learn more about metal printing applications!

What applications is the Metal X suitable for? How do I design correctly for metal 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Hinterlasse einen Kommentar