Our customer Primetall requires custom fixtures for some components to clamp them onto a TRUMPF laser welding machine. These fixtures were previously made of aluminum and were very heavy and expensive to manufacture.

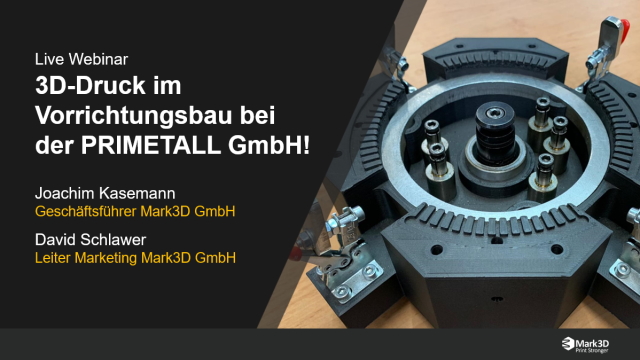

After some consideration, this fixture was optimized using additive manufacturing with a Markforged 3D printer. The fixture was reinforced with continuous carbon fiber. Furthermore, a zero-point clamping system was installed and channels were integrated inside the fixture. Now, forming gas can be directed wherever it's needed – with just one gas connection! It's practically "drilled around the corner." This is manufacturing redefined.

The figures in comparison speak a clear language:

Aluminum fixture: 1200€

3D printing fixture: 140€

Savings: 1060€ per device

12 devices are needed for one test series!

Webinar “3D printing in fixture construction at PRIMETALL GmbH”

In this live webinar, Joachim Kasemann, Managing Director of Mark3D GmbH, will use a concrete application example to explain the advantages of 3D printing for PRIMETALL GmbH and how the problem could be solved with customized fixtures.

Request a DEMO component now!

See for yourself how strong the components are.

Hinterlasse einen Kommentar