Automotive parts with metal 3D printing

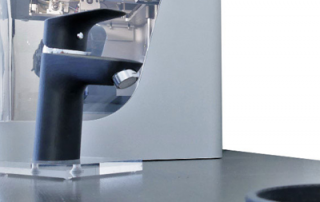

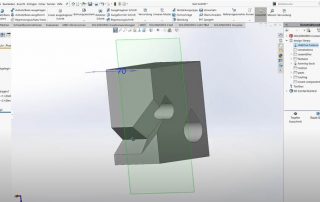

Components for classic cars from a modern 3D printer? 🤔RPG Industries, Inc. needed a new carburetor cover for an old classic car, but it was no longer available anywhere in the world! Conventional manufacturing was simply too expensive. While searching for options, the team came across Markforged 3D printers. With the help of a scan and reverse engineering, the component [...]