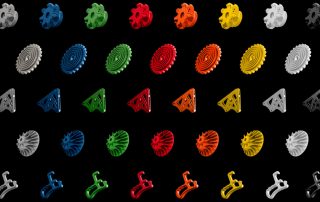

Step by step from CAD design to additively manufactured component

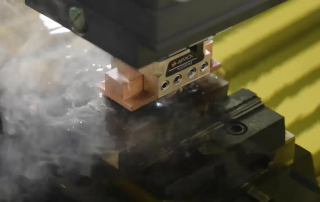

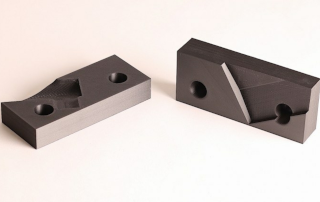

In our last live training, our Project Engineer Jan Geese presented the entire process from design to the finished component. What steps are necessary? What do you need to consider? Which data format is required? Jan answered these questions and much more in detail. We've never presented the process so transparently before. [...]