Bridging interrupted supply chains with 3D printing

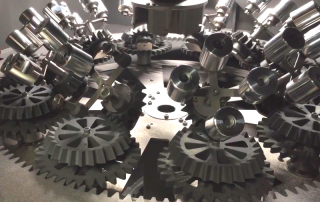

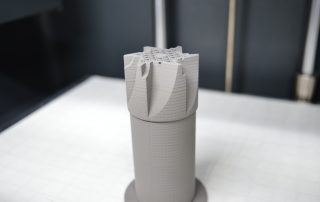

How 3D printing can help in the fight against the coronavirus. 3D printing can help shorten the supply chain, but it's not a panacea. We are waging war against the coronavirus – COVID-19. In times of war, logistics and supply chains are critical to success – and ours are so tight that they're beginning to break. 3D printing – from [...]