Components for special machine construction

The Berger Group has been building grinding and polishing machines in Wuppertal-Cronenberg since 1957. It is a leader in CNC and robotics technology.

As a specialist in grinding and polishing technology for the production of workpieces for a wide variety of industries, such as cutlery, hand tools, surgery, and woodworking, the Berger Group has made a name for itself.

Project goals

Lightweight and Stable Components with Complex Geometries

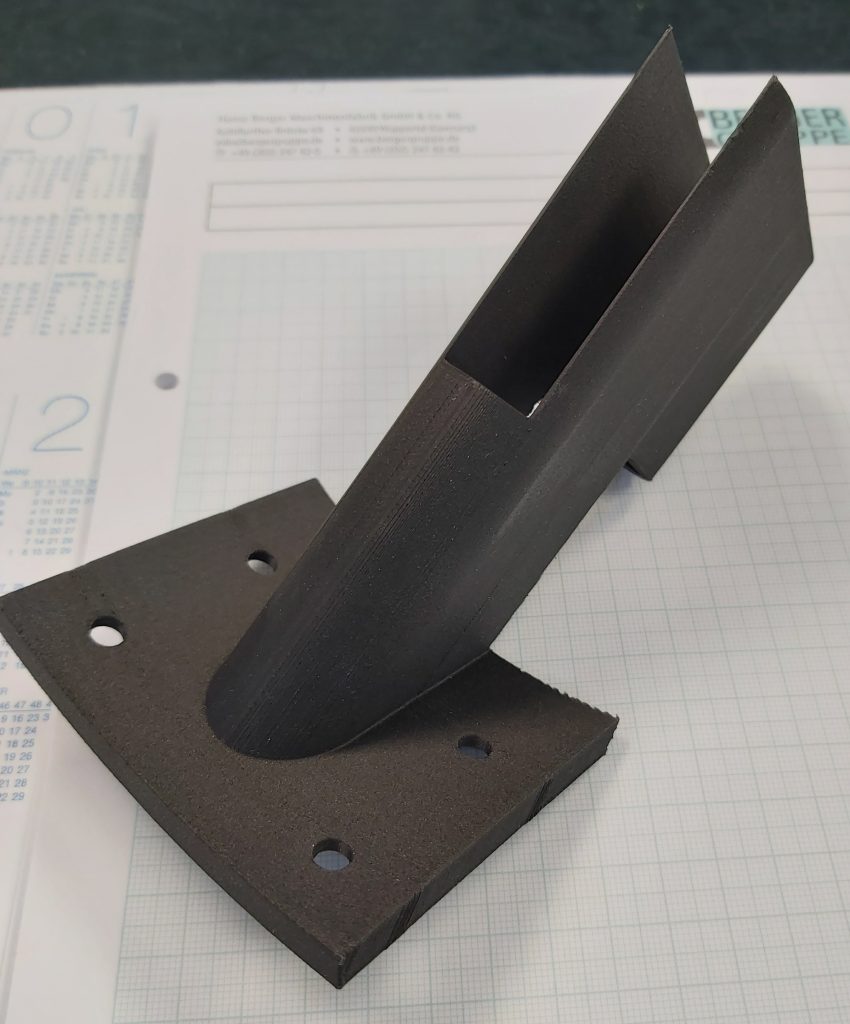

A fixture was needed for a laser marking system that was both lightweight and stable. "We saw 3D printing as the only viable option for manufacturing the base angle," says Frank Ohliger, Head of Assembly and Process Engineering.

Previously, the parts were conventionally manufactured from aluminum using CNC milling machines. Thanks to the continuous carbon fiber, the printed components are just as good as their conventionally manufactured counterparts!

Sensor Holder

50% cheaper than with conventional methods

In this application, a holder for a distance sensor was designed. Conventional manufacturing would have been very complex. 3D printing reduced manufacturing time and costs by 50%.

Laser Goniometer

3D Printing Complex Geometries Easily

A goniometer was developed using a standard laser pointer. A goniometer is used to check the cutting angles of knives or industrial blades. The laser beam is directed onto the sharpened cutting edge and projected onto the scale at two angles. This allows for quick and easy angle checks.

Here, too, conventional manufacturing methods would have been too expensive due to the complex geometry.

At a glance

Request a DEMO component now!

See for yourself how strong the components are.

Implementation

The Berger Group chose a Markforged 3D printer because of its ability to reinforce components with continuous carbon, Kevlar, or fiberglass fibers. Furthermore, other components, such as nuts, can be inserted during the printing process. The Markforged Mark Two is now used to manufacture robot grippers, initiator holders, molded parts, and much more.

The 3D printer also impressed with its simple plug-and-play operation and low error rate. Thanks to the excellent surface finish, the printed components look like they were purchased from a specialist retailer.

The future

With a team of highly qualified employees, increasingly advanced solutions have been and continue to be found through constant, consistent innovation and further development, with the implementation of user-specific machining tasks being a particular strength.

“We are extremely satisfied with the Markforged 3D printer!” – Frank Ohliger, Head of Process Engineering & Assembly

“How would I summarize the Mark Two in a nutshell? Easy to use – precise results!” – Timo Peters, Process Engineering & Special Design

Learn more about the applications with the MarkTwo!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.