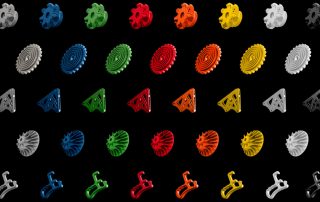

Individual gripping systems from the 3D printer

Custom gripping systems from the 3D printer. In the field of automation, gripping systems are often used to add, remove, or sort components. When we think about movement, we want to reduce weight. Therefore, the goal is to create a gripper that functions with the lowest possible weight, high stability, and longevity.