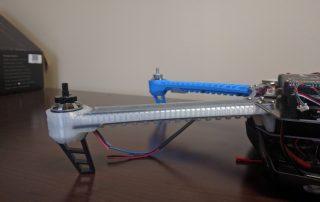

Embedding nuts in 3D printing

Markforged Mechanical Features Most 3D printing plastics aren't strong enough for printing threads. Their yield strength is significantly lower than that of metals. Even fiber reinforcements don't protect against high wear. Precision and high connection strength can only be guaranteed with metal threads. We've already explained how [...]