Parts from the 3D printer – the endurance test at Spühl GmbH

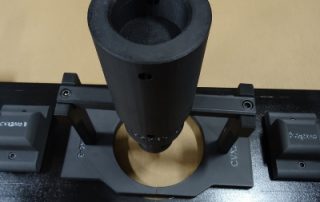

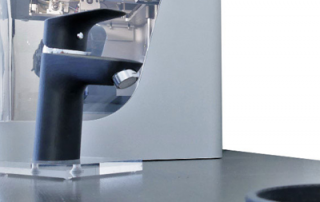

3D-printed parts - the endurance test at Spühl GmbH "With this test, we wanted to demonstrate our confidence in a mature technology, both for ourselves and for the company." – Markus Widmer In the endurance test, the components printed on a Markforged 3D printer withstood a load capacity of over [...]