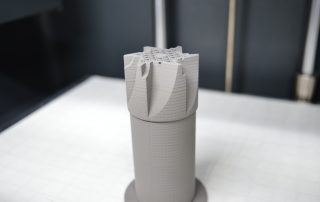

Wärtsilä produces the world's first 3D-printed CE-certified lifting tool

Here you can see the world's first CE-certified, 3D-printed lifting tool, manufactured by Wärtsilä using a Markforged 3D printer! The lifting tool assists in the maintenance of engines on assembly lines worldwide and can lift a whopping 960 kg (with a safety factor of 4)! This is manufacturing redefined. 100,000 EUROS SAVED WITHIN 8 MONTHS 75% WEIGHT SAVINGS 960 kg [...]