Bringing tomorrow's production into today

Automation at erler GmbH

erler GmbH's passion: automation technology and robotics.

Based in Dormettingen on the Swabian Alb, erler GmbH builds robot cells for handling technology to position customer-specific workpieces from A to B, subject to certain cycle time and quality requirements. The supply and removal of parts is also an issue.

erler GmbH therefore manufactures semi-automatic and fully automatic machines that are used in assembly, machine loading and unloading or test automation.

Project goals

More flexibility and efficiency through in-house production

The challenge for erler GmbH was that a lot of time and money had to be spent on special machine construction as well as individual and development parts.

Previously, the workpieces were outsourced to various suppliers for external production. The goal was to bring the added value in-house to achieve greater flexibility, independence, and cost-effectiveness.

Now we can react much faster, as Managing Director Michael Müller explains: "When we have a part to grip, we briefly consider 'is it even possible to manufacture a gripper for it? We print a prototype overnight and can test it straight away in the morning. We no longer have to spend money ordering from a third-party supplier!"

At a glance

Implementation

Excellent tensile strength and quality for mechanical engineering thanks to fiber composites

At the SolidWorks Experience Day, Michael Müller, one of the three managing directors of erler GmbH, got to know the Markforged 3D printers.

"We evaluated two different options: One was to purchase a CNC milling machine for aluminum and POM, and the other was to get into additive manufacturing. Costs, quality, production times, flexibility, innovation and personnel were compared."

If they had gone into the machining sector, they would have had to hire an additional industrial mechanic and start from scratch.

The main reasons for additive manufacturing were that erler GmbH has found a very good tensile strength and quality for mechanical engineering with the printing process using fiber composites from Markforged and can now manufacture parts flexibly - without additional personnel.

"For example, we manufacture workpiece holders, gripper fingers, sensor and cylinder holders and even possible assemblies for conveyor belts with the Markforged 3D printers," says Michael Müller, who is responsible for mechanical engineering and technical sales.

Request a DEMO component now!

See for yourself how strong the components are.

Solution

Newfound flexibility and independence

When it was announced that a 3D printer was to be brought into the company, employees reacted partly critically, partly with fascination. But even the first tests on the tensile strength of the components convinced the critics. "It's great for the designers to work with it, they're really happy!"

The Mark Two is used exclusively by the mechanical design department, which in turn develops machines for various industries such as medicine, automotive, plastics processing and machining.

Customers' opinions still differ. For example, when it comes to the high demands of medical technology, customers do not yet trust a 3D printed part to perform as well as a machined, surface-treated part can. Here, a fibre composite material is in competition with an anodized aluminium part. This is still viewed skeptically and we still have a lot of convincing to do. Plastic parts are even used in the medical technology cleanroom.

In the medical sector, for example, a stainless steel workpiece is screwed to the point where the gripper touches the product. This enables erler GmbH to meet the FDA requirements for surfaces that come into contact with the product. The same is also applied to parts for abrasion, so that the stressed areas are made of wear-resistant materials.

Various suppliers also supply 3D printed parts, but 95% are milled because the tensile strength cannot be achieved with their printers. The image of 3D printed components is often still that they are brittle, have beautiful surfaces, but are not suitable for mechanical engineering. This is different with the Markforged machines.

The greatest added value is the newly gained flexibility, but also the independence from suppliers. Prototypes and feasibility studies for the sales phase, in which the mechanical solutions are presented to customers, can now be printed unmanned overnight.

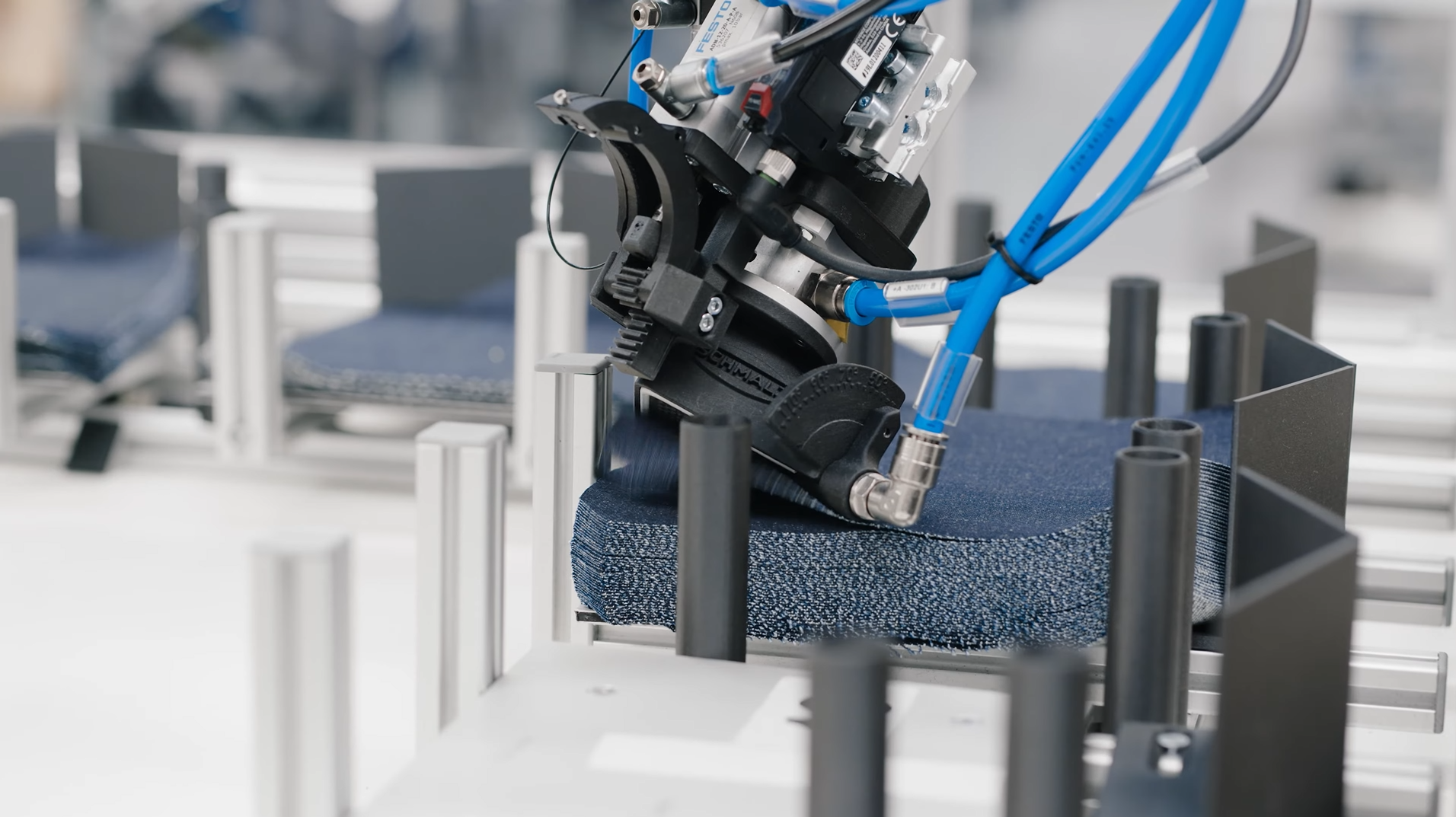

For example, the robot flange and the grippers themselves are now printed, as these are very workpiece-specific. Whether a medical technology assembly or an automotive bent part is to be gripped - the gripper must be individually designed for the environmental conditions.

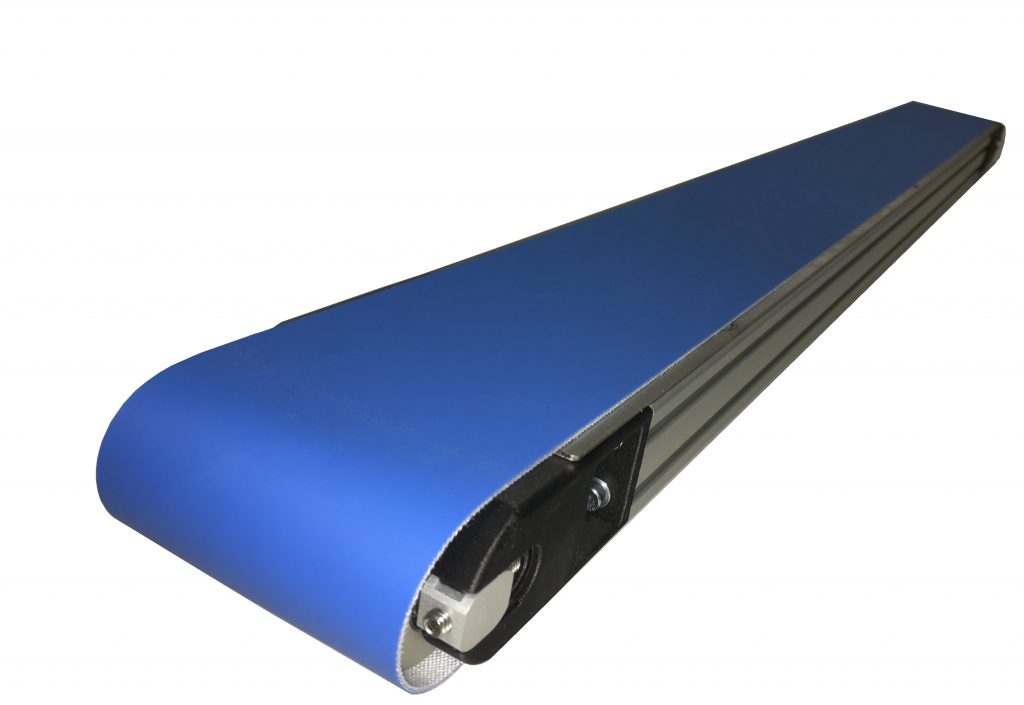

There are also various accessories for feeding and removing parts to and from the robot: Brackets for conveyor belts, brackets for flexible feeders, parts for the conveyor belts themselves or sensor brackets.

The future

Learn new techniques and build up knowledge

The design engineers learn something new every day and are happy to have such a reliable and process-safe production machine at their disposal.

"The aim is to offer our customers added value with additive manufacturing. This means we can also support our customers with additional assemblies for automation technology, such as printed grippers or printed conveyor belts.

In the next step, we want to focus on components and integrated inserts in additive manufacturing as well as Metal X," says Michael Müller.

“With the Markforged Mark Two, we have a process-safe, reliable, and innovative production machine – without additional personnel costs!”

– Michael Müller, Managing Director of erler GmbH

© Zollern Alb Kurier - The picture shows the three managing directors of erler from left: Michael Müller, Holger Erler, Jochen Erler

Practical report:

In a current project, erler GmbH is working with Robotextile to support C&A Fit in bringing parts of the jeans production back to Germany in order to restore stability to the supply chains.

In addition, the products in particular should be produced sustainably and highly productively, explains Jürgen Mohs in the video.

The black Markforged Onyx components are clearly visible in the video.

Learn more about the applications with the MarkTwo!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Would you like a demo, have questions or need a quote for a Markforged 3D printer?

Contact us now!

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.