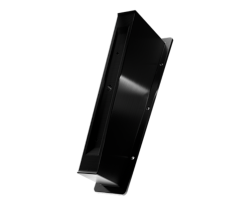

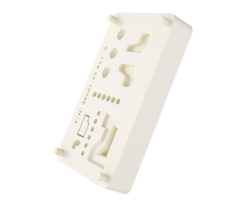

Base materials (plastic matrix)

With Fused Filament Fabrication (FFF), the printer heats the thermoplastic fiber until it almost reaches its melting point. The material is then applied layer by layer through nozzles, creating a plastic matrix. Markforged 3D printers print all thermoplastics using this method.

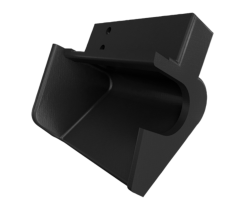

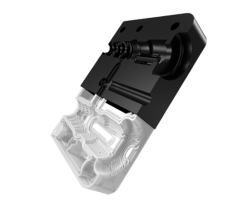

Composite materials (continuous fiber)

Continuous Filament Fabrication (CFF) is our unique and patented technology that significantly strengthens 3D-printed components using a continuous filament. Continuous fiber strands are laid within the thermoplastic matrix. The user decides which layers are reinforced. They also specify the amount of reinforcement needed, the direction in which the fibers should be arranged, and the type of material used. The goal of fiber-reinforced 3D printing is to produce components stronger than aluminum!

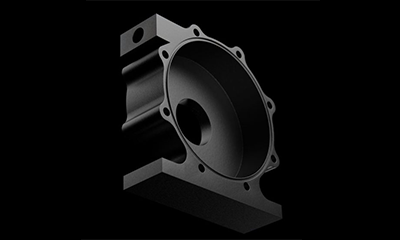

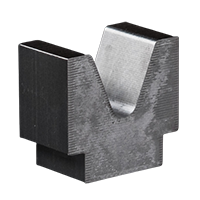

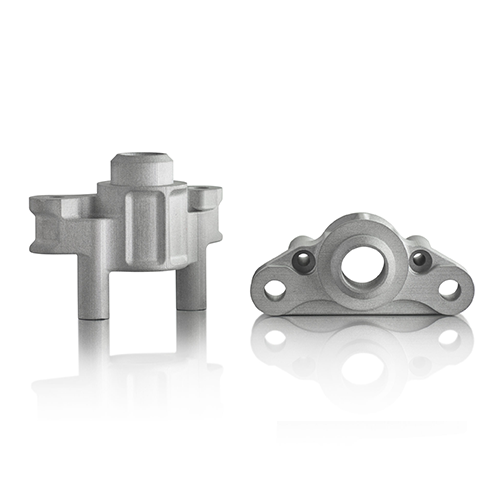

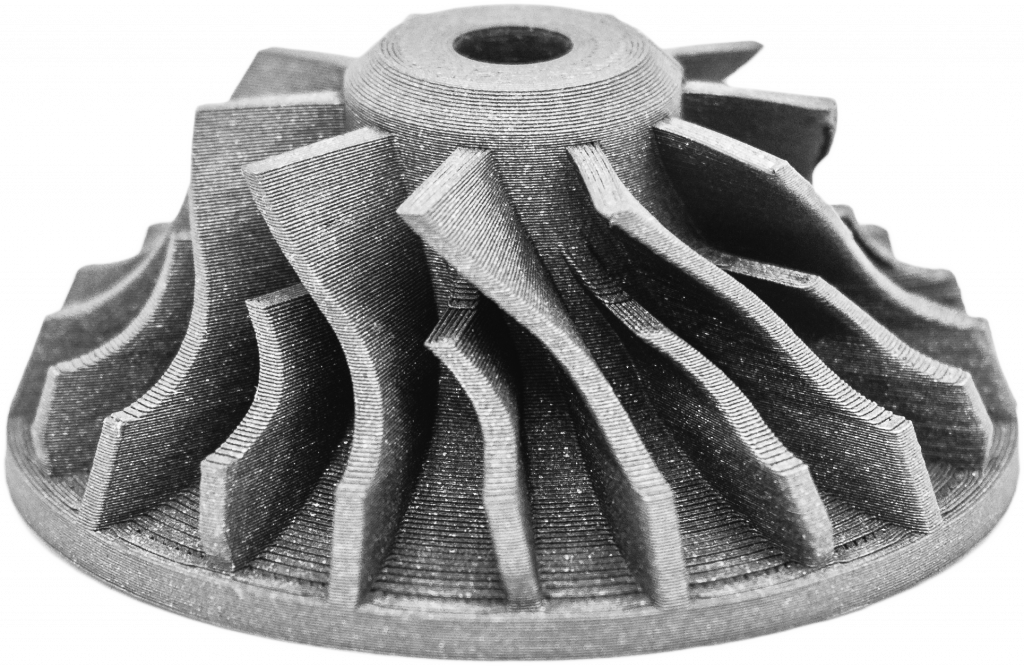

Metal X Metals

The combination of proven MIM (Metal Injection Molding) technology and our unique 3D printing platform ranges from prototyping to production using the same materials and processes.

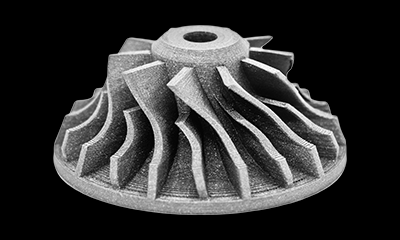

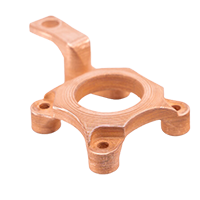

PX100 Metals

The binder jetting system enables the series production of everything from industrial components to medical and consumer goods.

Alloy 625

625 is a nickel-based superalloy. They are weldable superalloys suitable for high-temperature applications in aerospace, for example.

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Learn more about metal printing applications!

What applications is the Metal X suitable for? How do I design correctly for metal 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.