Strength, precision and beauty

Markforged doesn't just offer strong materials. While our CFF (Continuous Fiber Fabrication) materials are engineered for high-strength applications, Markforged also takes care of the exterior of your parts. The resulting parts look, feel, and behave like the finished product, eliminating numerous barriers between design and final product.

"Someone once asked me why we cared so much about what the printer looked like and how it was built, and my response was, 'If we don't care about what our product looks like, why would you think we'll care about what your part looks like?'" - VP of Product Jon Reilley

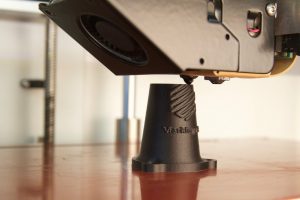

Onyx brought us a big step closer to this goal. Its smooth, matte black finish has enabled users to print parts that can be sent directly to customers. Furthermore, the material is tough and strong enough to survive almost anything—from robotics to industrial automation. Onyx can be printed on its own or combined with one of our CFF composite fibers for additional reinforcement for high-strength, high-quality parts.

Onyx parts come ready-made from the build plate and can be used directly in production.

3D printing for end applications

Alan Rencher, CEO of Media Blackout, uses Onyx: "We can manufacture anything our customer needs. We can help them design something to make their workflow more efficient. Since we get a lot of orders for small quantities or individual parts, 3D printing is a good way to produce cost-effectively... it's fairly fast and not as expensive as other manufacturing methods."

Camera equipment is often bulky and heavy, so many of its parts need to be strong, slim, and lightweight. "We make a lot of parts that need to be lightweight and very rigid... we have parts where we need to eliminate vibration or support a certain amount of weight," explains Rencher. "We saw that Markforged offered carbon fiber printing, and we thought that would be a good option."

The BreakerBatt, an electronics connector and housing for film cameras, is one of many pieces of equipment that Media Blackout manufactures.

With Onyx's surface texture and the strength of its carbon fiber reinforcement, custom production for Media Blackout is easy. Other manufacturing methods are time-consuming and costly. "The new material looks exactly like a finished product," he explains. "This helps us create parts that go straight to market." Onyx comes ready-to-print from the print bed and can be shipped directly to the customer.

This article was originally published on the Markforged blog. Here go to the original article.

Translated by Antje Kasemann

Hinterlasse einen Kommentar