Learn how students at Oklahoma State University and Purdue University are using 3D printers.

We often report on the various tools, fixtures and production parts that so many companies around the world are making with markforged technology. But it's not just companies that benefit from additive manufacturing.

Universities are beginning to educate students about 3D printers to learn where they can best be integrated into the manufacturing process. From concept to design to production, 3D printers support all necessary steps in the manufacturing of functional parts. Here's how two universities are using Markforged technology to help students understand the value of additive manufacturing.

Request a DEMO component now!

See for yourself how strong the continuous fibers are.

Oklahoma State University

"What you can achieve with additive manufacturing - you can't achieve with subtractive manufacturing. The ease of use of additive manufacturing accelerates students' ability to go from concept to part. However, our job is to teach students about both additive and subtractive manufacturing and the strengths, weaknesses and connection between the two technologies. I don't want to brag, but we do this throughout the College of Engineering Architecture and Technology (CEAT) from the very first semester!"

At Oklahoma State University's College of Engineering, Architecture and Technology (CEAT), students have access to the ENDEAVOR facility. ENDEAVOR is a 72,000-foot facility with 12 labs, five MakerSpace locations and five design labs - as well as offices and other non-lab space. In total, the facility is used by 1,500-2,000 students annually and supports 38 courses from eight technical departments.

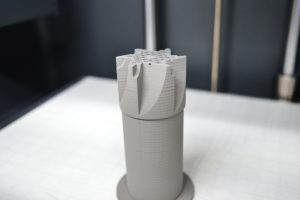

The industrial equipment used to train future engineers at ENDEAVOR includes two Onyx Pros, two Mark Twos, an X7 and a Metal X. "Markforged came on our radar because of its Onyx and continuous fiber reinforcement printers. "That really interested us," says Dr. Brad Rowland, ENDEAVOR operations manager at Oklahoma State University.

Rowland explains that he hopes the Metal X will help elevate OSU students over others. "The ability for students to print with metal would be a huge win for student design projects," Rowland says.

The students are currently using the composite printers for various projects, ranging from remote-controlled cars to specific projects involving unmanned aerial vehicles. "We already have two student-developed products under review for patenting. One of them will use the Markforged Mark Two printers in its manufacture," says Rowland.

ENDEAVOR offers students the opportunity to go from idea to part in hand, often producing parts that cannot be made using conventional manufacturing - or parts that combine subtractive, additive and other techniques such as casting.

Purdue University

"We use the analogy that we are like a gym. We offer training and we have the equipment, but you have to come in and bring the commitment and determination."

Purdue University established the Bechtel Innovation Design Center - a forward-thinking prototyping facility and manufacturing hub built by students for students. "Students can pretty much make anything they want," says David McMillin, associate director of the facility.

The center offers students 3D printers for everything from electric skateboards to electric race cars. The technology available is free to all students - and there are 400,000 of them. Students have the opportunity to use 20 cloud-enabled 3D printers, including two Markforged Metal Xs and two Mark Twos, as well as traditional manufacturing equipment such as CNC mills, CNC lathes and a full woodworking shop. The idea behind the center is that students come in, try to develop something, and drive a product from idea to implementation.

"3D printing is a really good way to introduce and excite people about manufacturing with low effort and low risk," says McMillin. The center has more than 20 student mentors to assist anyone who wants to use additive manufacturing for their project. According to McMillin, the Mark Two's level control is something that students like best. "The resolution, accuracy of fit and surface finish you get from it is unparalleled. They print reliably and the surface finish is beautiful coming straight off the machine."

The students have found several uses for the Metal X printer, which can currently print in 17-4 stainless steel and H13 tool steel. The Metal X has been used to print joint mounts for race cars to hold rod ends in a race car as well as a Mach 2 wind tunnel test target. "It's obvious that the industry is working very hard to develop and perfect metal 3D printing technology and that this is something people are interested in. Our students, professors, the university and the world are expecting this technology."

Hinterlasse einen Kommentar