The EIGER software offline

Keep 3D printing software up to date in offline mode

The ability to access the latest software features is one of the primary reasons customers choose cloud-based applications. Because software vendors are able to push updates to the cloud as soon as new code is available, cloud users can immediately benefit from new and improved features.

When cloud connectivity isn't possible, users often have to rely on locally installed software that may not have been updated in years. When on-premises software is frozen in time, the benefits for users of the software are also lost.

So what does a user have to do?

Software updates close this gap between cloud and on-premises software. Regularly installing new software versions allows offline users to easily keep up with the cloud.

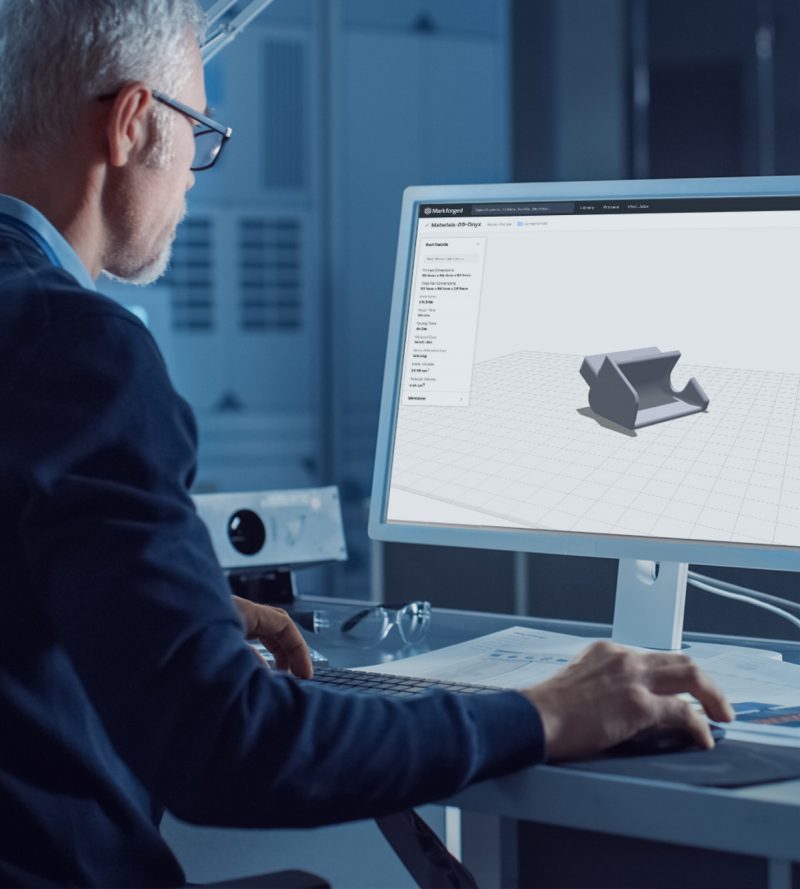

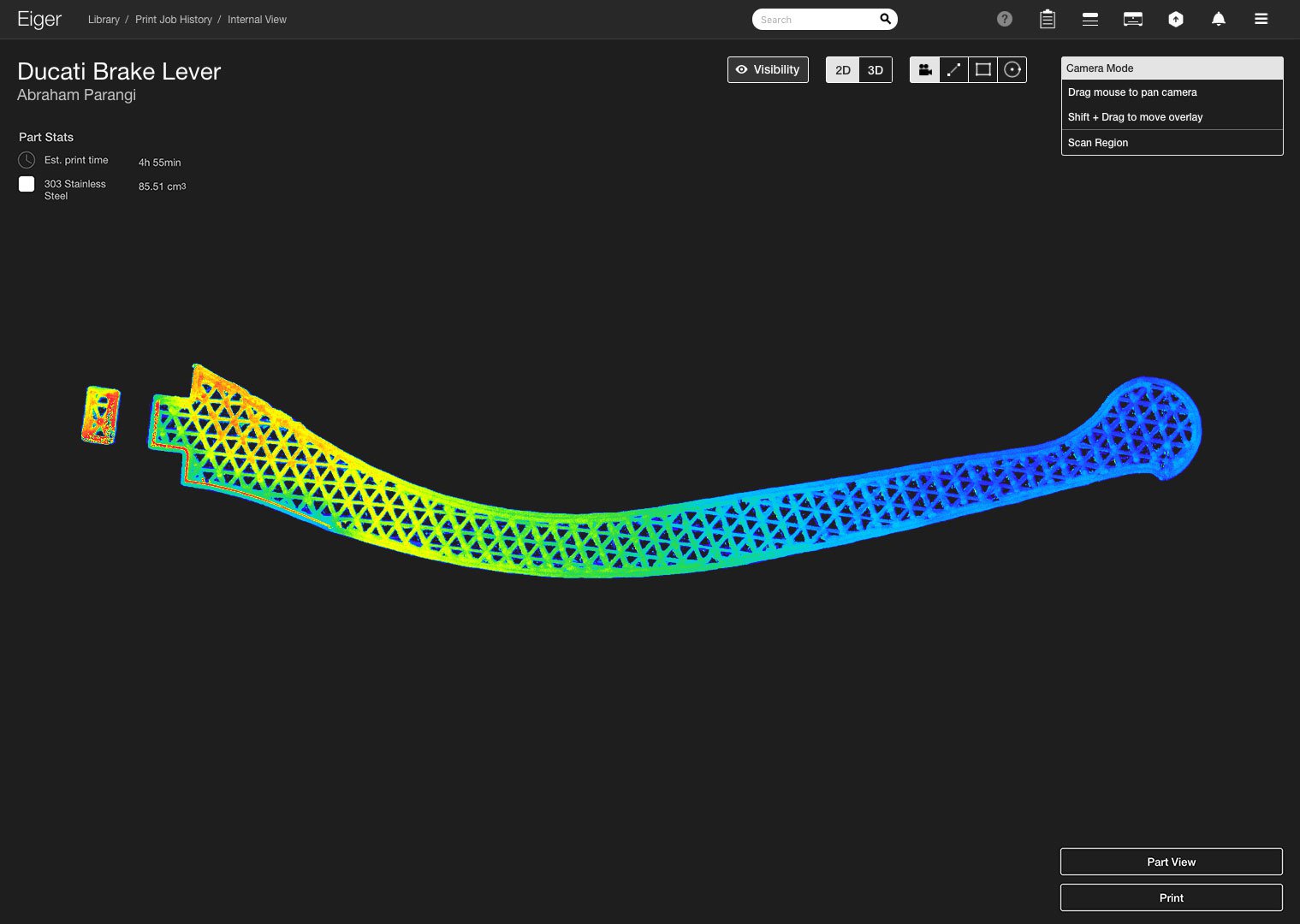

At Markforged, most of our customers use Eiger for 3D slicing and printing in the cloud. For companies that need to store their or their customers' part information on local systems, we offer Offline Eiger, which operates 100% offline. For the past year, Offline Eiger has been available as a subscription to help our customers bridge the gap between cloud and on-premises software with quarterly updates that provide the latest features and material support.

Below are examples of new features for offline Eiger users that take advantage of the seven software updates released so far:

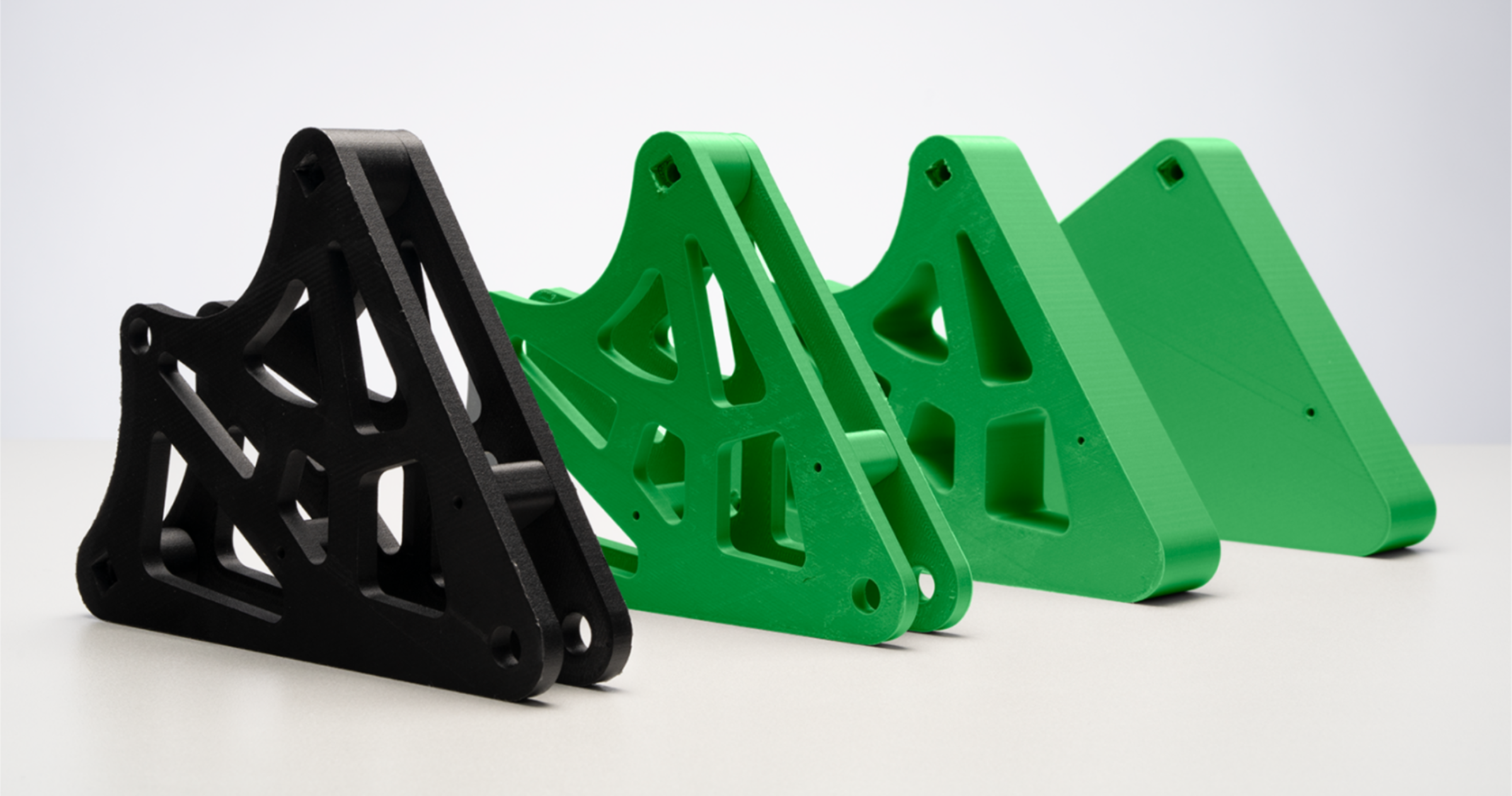

Precise PLA

17-4 PH stainless steel v2

Gyroid infill (40%ige density)

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Would you like a demo, have questions or need a quote for a Markforged 3D printer and the EIGER software?

Contact us now!

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396-00

E-mail: markforged@mark3d.de

To contact us, please fill out our secure form.