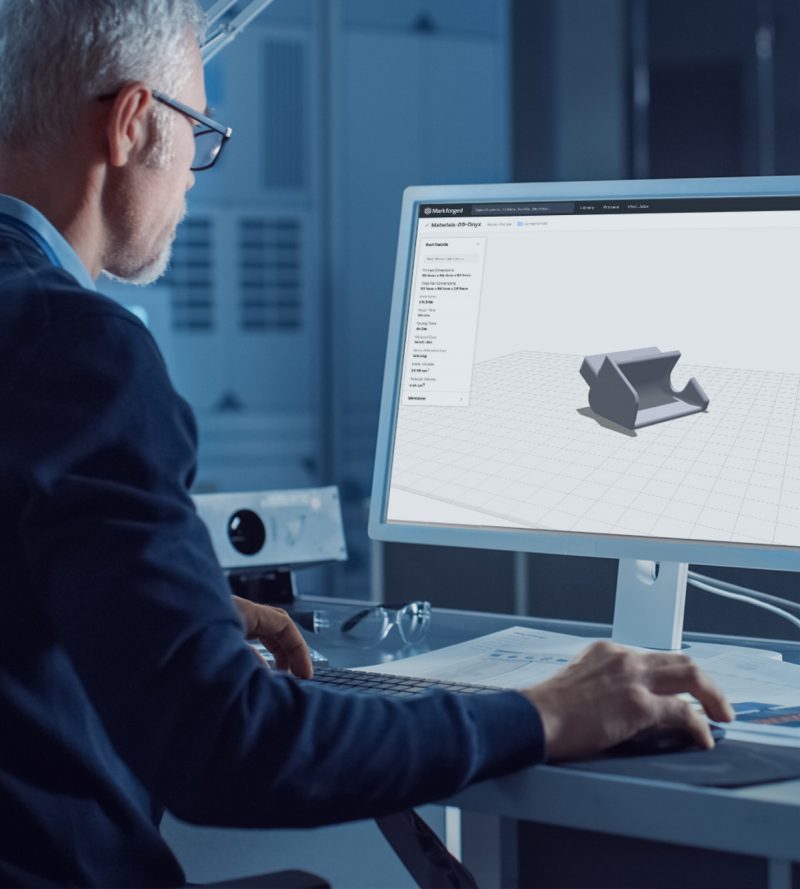

The EIGER software

3D printing with high-end printing materials and continuous fibers

The dynamic additive manufacturing software that allows you to print any part on demand, exactly where it is needed.

Preparation. Printing. Management. Scaling.

Meet EIGER. With Markforged's dynamic additive manufacturing software, you can print any part on demand from anywhere in the world.

From design to component – easier than ever before!

Eiger is an integrated, connected platform that quickly takes you from CAD model to functional component. The browser-based workflow is secure, fast, and intuitive.

The Markforged EIGER software is powerful and very easy to use. Your parts can be quickly optimized with the right settings and fiber orientations to optimally design your part for your application.

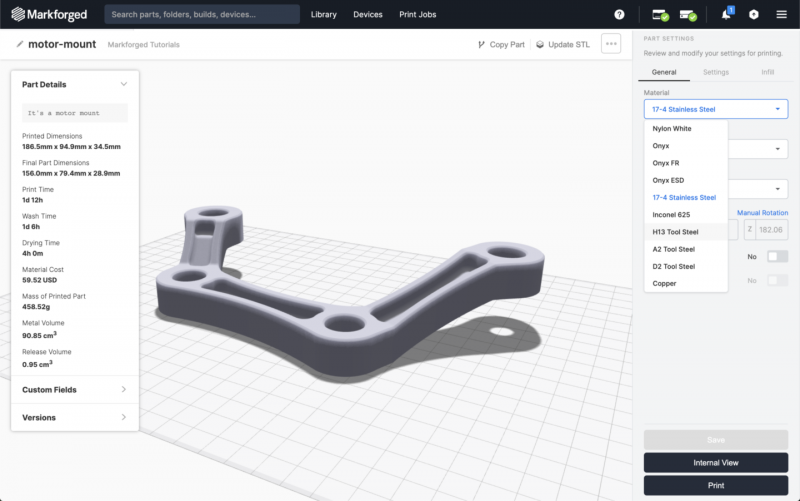

Print with continuous fibers, composites and metals

With Eiger, you can print metal or composite parts reinforced with continuous fibers. You can prepare parts for printing with a single click or drill down into part settings to optimize your final product.

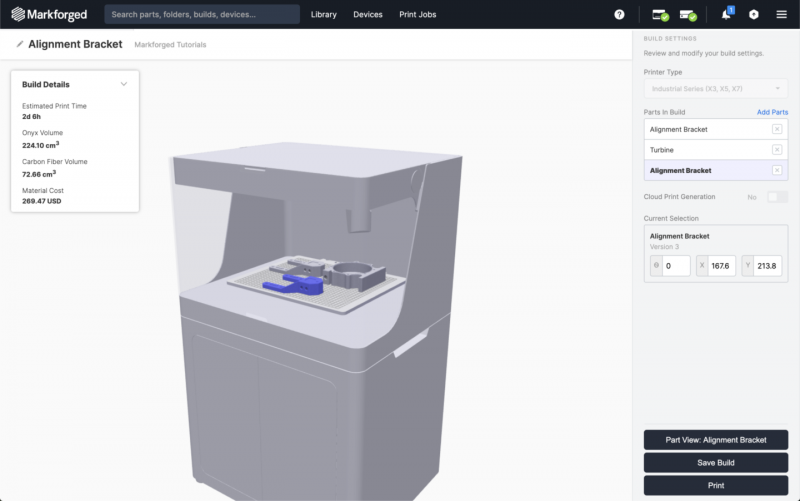

Seamless interaction with printers

Eiger is fully integrated with all Markforged 3D printers, allowing you to design parts, print parts, and monitor the printing process in one seamless workflow.

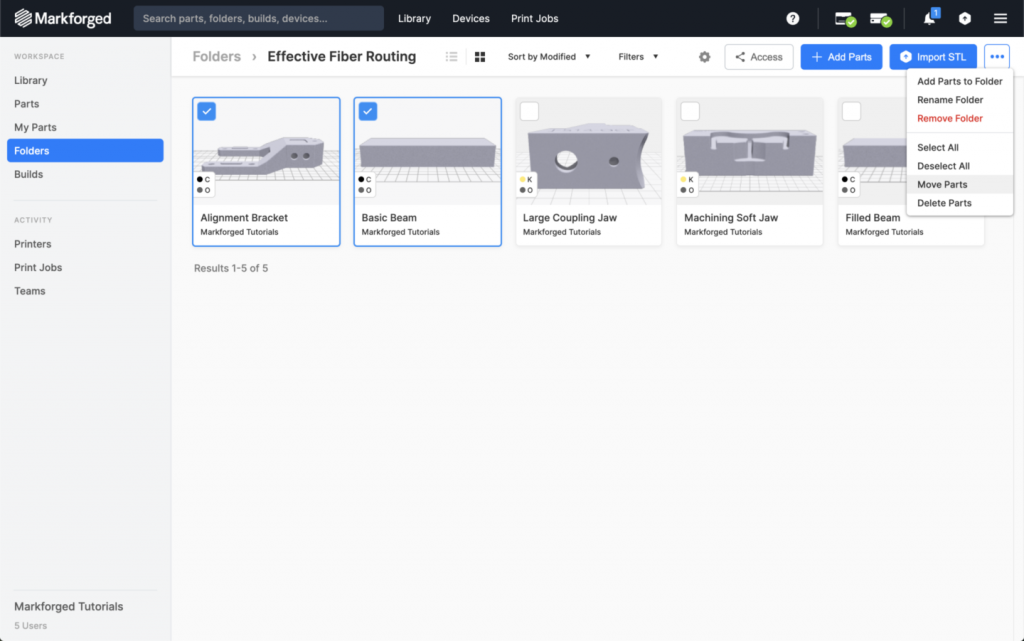

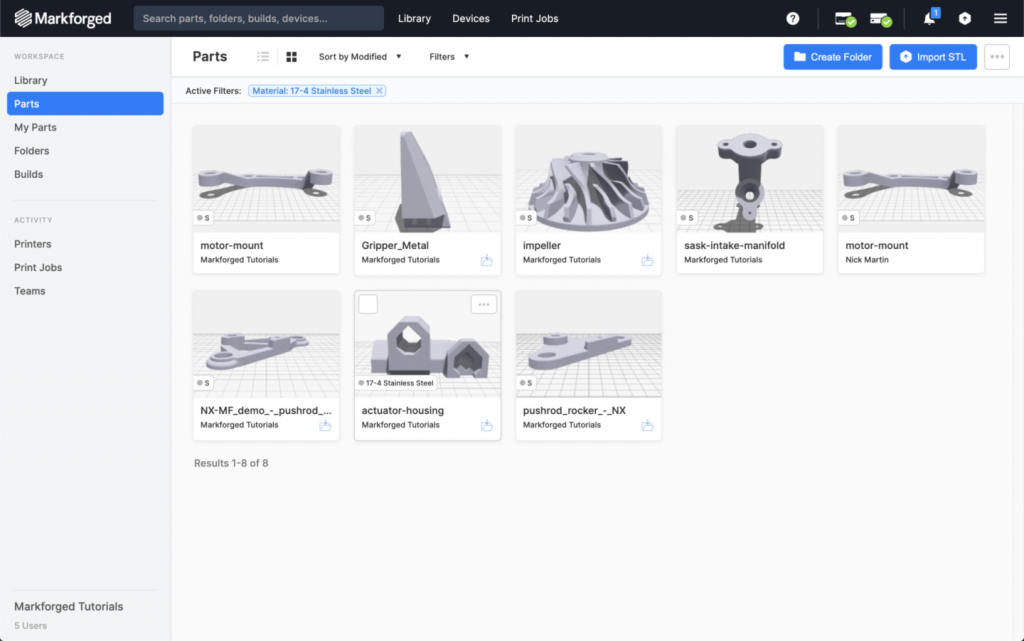

Conveniently store and retrieve components

You can easily upload the component created in the CAD program (e.g., SOLIDWORKS) as an STL file via your browser (Google Chrome) to the cloud-based Eiger software for Markforged 3D printers. There, you can manage and catalog your files.

After uploading the STL file, you can optimize it for your application with just a few clicks. For example, increase wall thickness, scale, adjust fill density, select honeycomb structure, adjust support structure, etc.

In the next step, you insert the fiber into the component. You can freely choose the layers in which the fiber should be inserted. There are three adjustable fiber placement methods to choose from. This allows you to perfectly design your component for the force application.

The printing process can be paused to embed components into the print. This allows you to print RFID chips, nuts, razor blades, or magnets into your component.

Manage projects with simple organizational features

Organize and organize your components intuitively and easily with folders. Sort components and projects alphabetically, by creation date, or by modification date.

Find the right component every time

Easy-to-use filters sort components by name, material or user – so you can always quickly find the component you need.

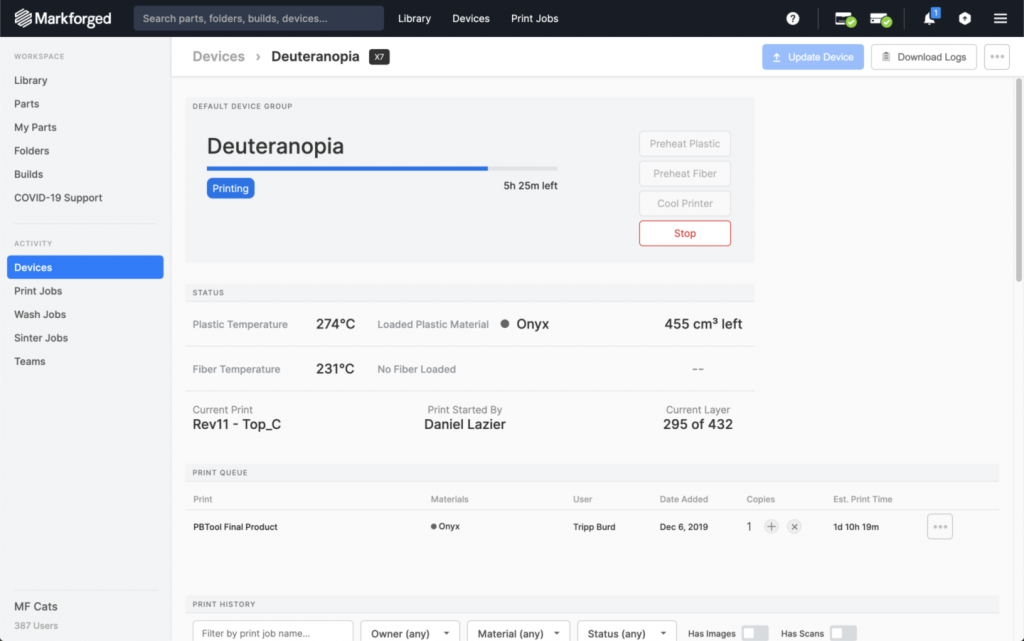

Monitor your systems in real time

With Eiger, you can monitor every connected device in your organization from anywhere in the world. Receive real-time updates on critical project progress as it's being executed.

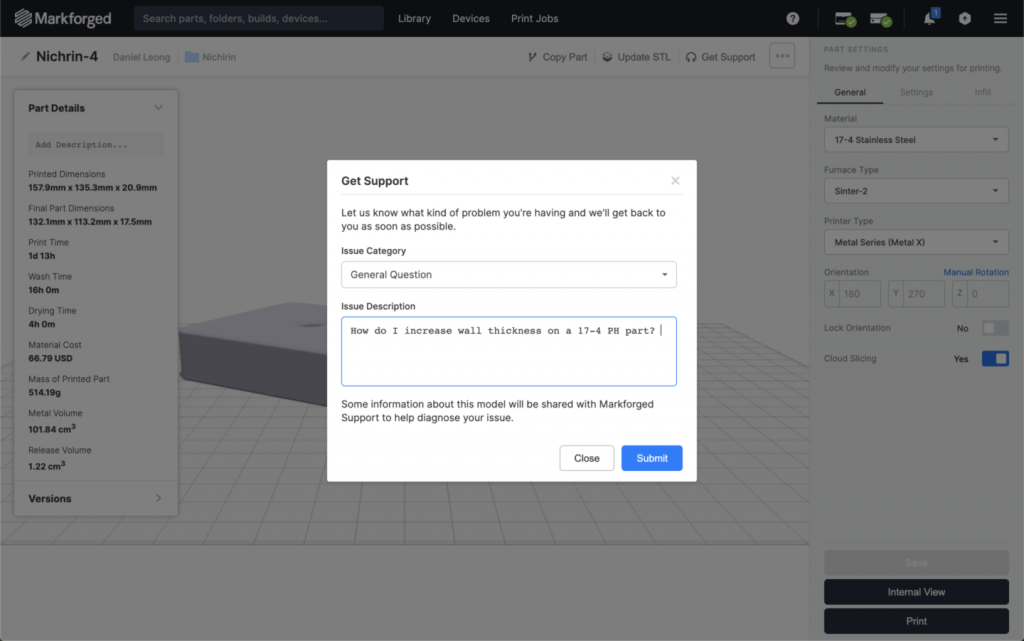

Integrated customer service

Eiger software updates are automatically delivered to your company, unlocking new features and continuously improving printer performance. Support is fully integrated into the software and accessible directly from the parts and printer pages.

Scaling your additive manufacturing – Eiger Fleet

Manage decentralized manufacturing operations at the enterprise and global levels with greater efficiency and better visibility.

Advantages of the Eiger Fleet

- Simple user management

- Connect, simplify and automate workflows

- Track, analyze, and share key performance indicators

Advantages of EIGER software

- Intelligent and very user-friendly software (plug & play principle)

- Manage and catalog components by projects and users

- Add additional users for free

- Integrated support with detailed help and video tutorials

- No updates or unnecessary storage space required as it is cloud-based

- Anytime access and login, as cloud-based with Google Chrome browser

Settings for optimizing the component

- name

- Scaling

- Placement of the component

- Selecting the fiber type (carbon, Kevlar, fiberglass)

- Selectable fiber fill type (Concentric, Isotropic)

- Presettable number of fiber-coated layers

- Adjustable number of fiber rings on the surface of the component

- Automatically generated support material for overhangs

- Brim option for better grip on the building site shape

- Metric or inch

- Printable layer height

- Component fill type (Hexagonal, Triangular, Rectangular, Full Fill)

- Adjustable filling density

- Adjustable floor and ceiling layer of the component

- Adjustable number of wall layers

- Adding notes and keywords for cataloging

Settings for inserting the continuous fiber into the component

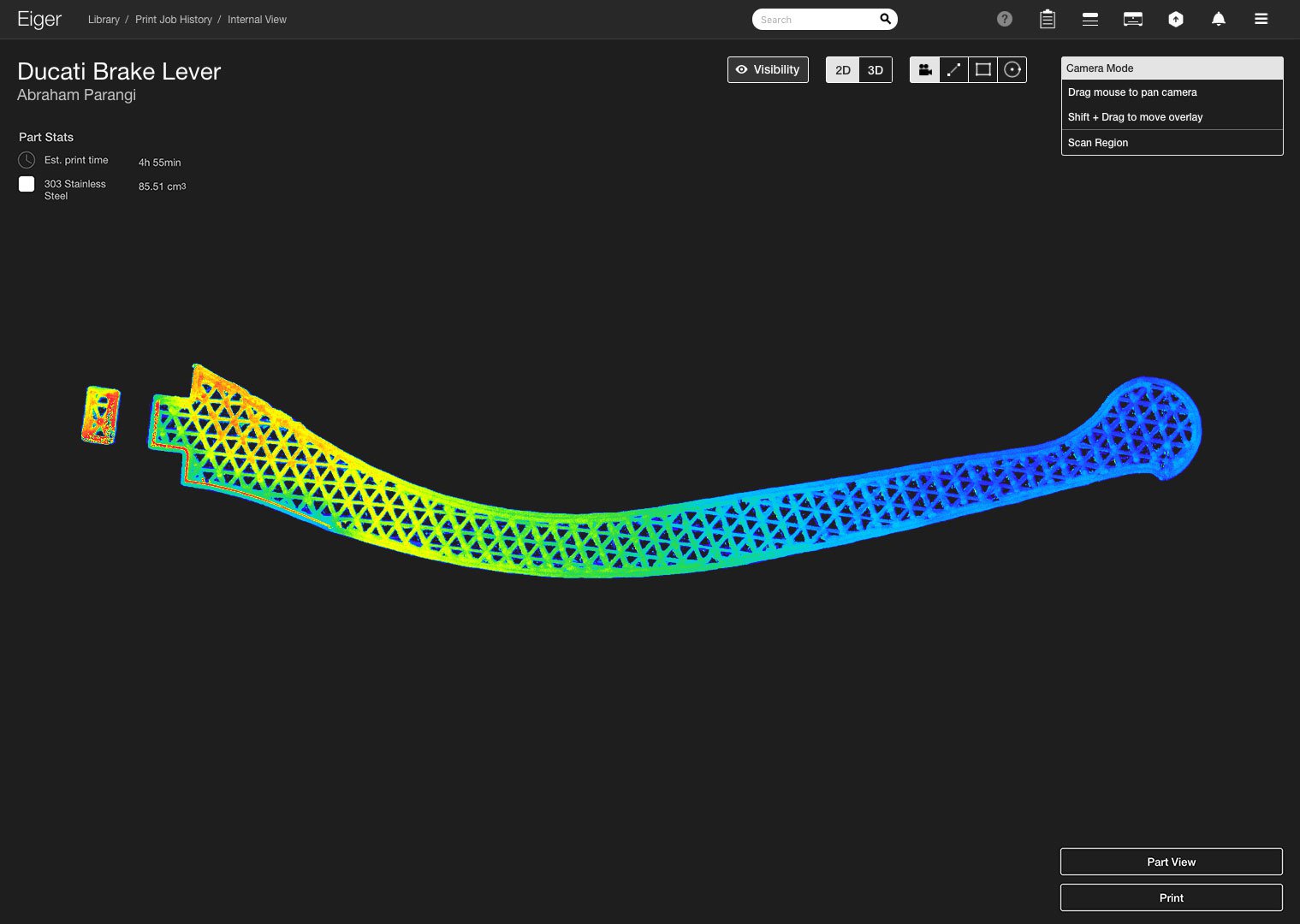

- View in 2D and 3D

- Freely selectable in which layers a fiber should be inserted

- Freely selectable fiber type (Concentric, Isotropic)

- Freely selectable how many fiber rings should be inserted onto the surface of the component

- With Isotropic Fill, an angle of the inserted fiber can be specified

- The printing process can be paused (e.g. for inserts such as RFID, magnets, nuts)

- Display of printing time and material consumption of Onyx and continuous fiber

- Hiding individual component sections

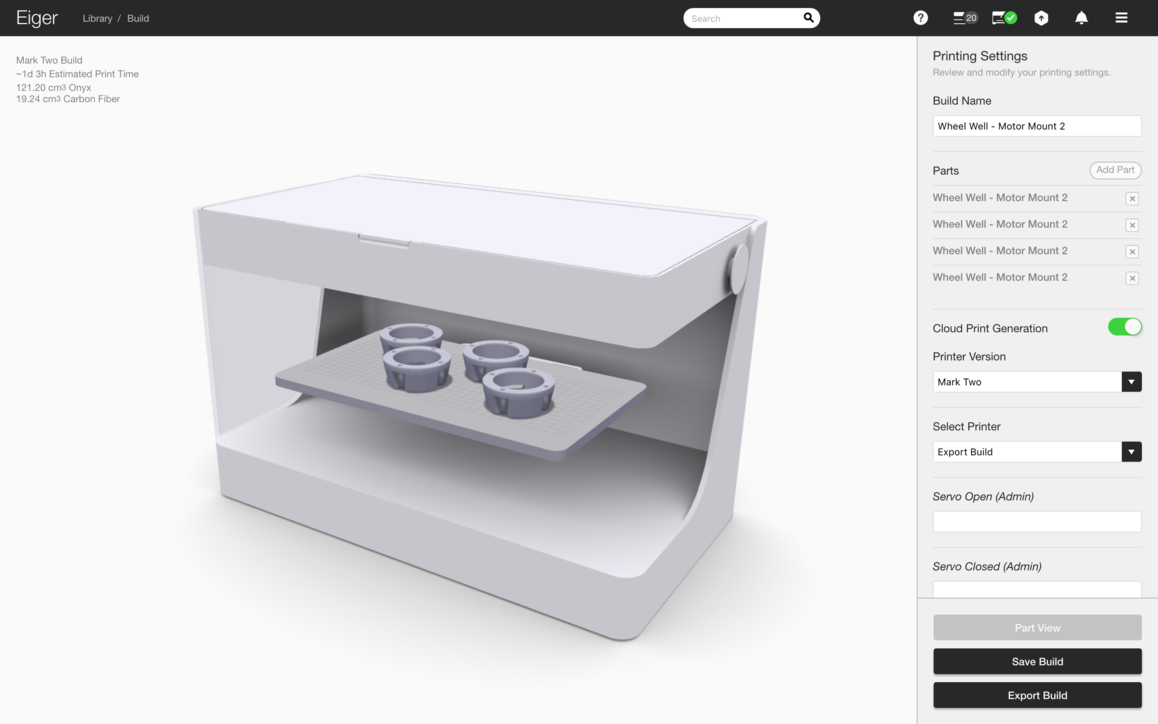

Print mode

- Positioning the component on the build platform

- Adding additional components

- Saving print configuration

- Download components and print configurations

- Monitor print progress online

Scaling your additive manufacturing – EIGER Fleet

As the latest addition to the Markforged Eiger software portfolio, Eiger Fleet was developed to help manufacturers integrate revolutionary additive manufacturing technologies into their conventional workflows.

Production-ready printer management

Eiger adds selective fiber reinforcement to your part for 3D printing on a Markforged machine. Thanks to its powerful fiber routing and slicing intelligence, the software is easy to use for any technician and allows for intervention when needed. Eiger's free, cloud-based platform is suitable for any size printer network, whether you use one or one hundred Markforged 3D printers.

Markforged takes the security and privacy of your data very seriously.

ISO 27001 – Security Certification

- Markforged is the only certified manufacturer in the additive sector.

- The certification was issued by an external testing body.

- Your data is safe in the EIGER software!

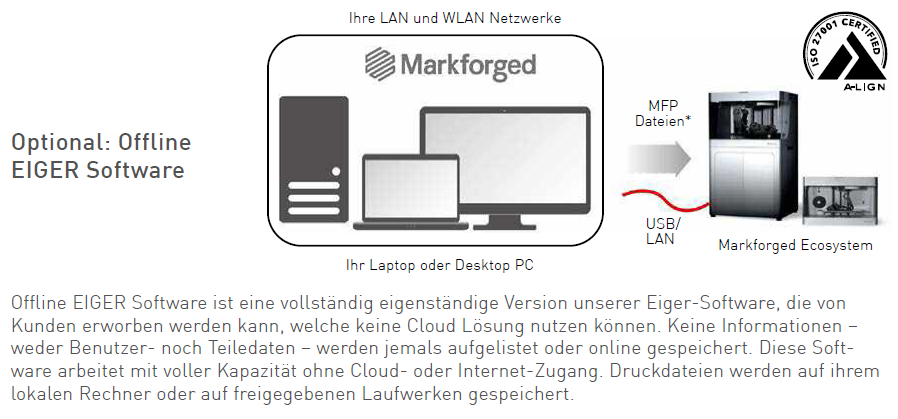

* MFP files (Markforged Print) are the unprocessed output data of the EIGER software, which the Markforged printers use to print the component.

** Application data includes account information for the license server, folder structures, printer settings and used material quantities/print volumes.

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Would you like a demo, have questions or need a quote for a Markforged 3D printer and the EIGER software?

Contact us now!

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396-00

E-mail: markforged@mark3d.de

To contact us, please fill out our secure form.