Fiber-reinforced 3D printing

[4 minutes reading time]

Why fiber-reinforced or composite 3D printing? What are continuous filament fibers (CFF)?

The strength of 3D printed components is often not sufficient. Initial samples or prototypes work, but beyond that the classic methods are used. If there are no metal shavings flying, it can't last - we hear this phrase again and again.

People are all the more surprised when they hold a component made of onyx with a continuous carbon fiber reinforcement in their hands.

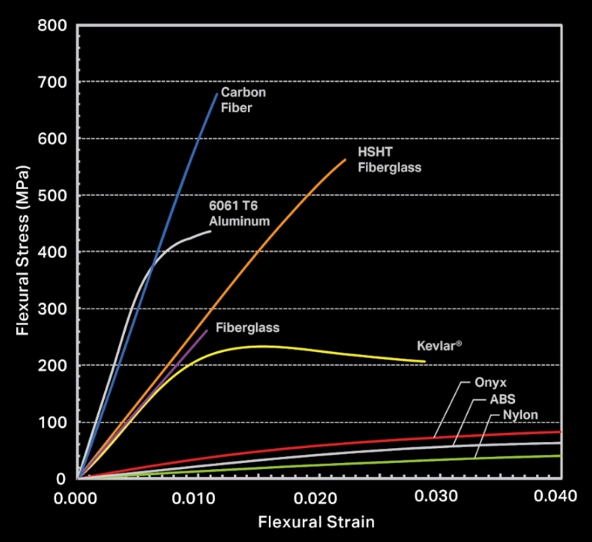

Even the base material Onyx is 1.4x as strong as ABS. The inserted continuous fibers even achieve strengths that are 23 times higher than ABS.

How does composite 3D printing work?

While short carbon fibers are remarkable for their ability to reinforce thermoplastics, continuous fibers can impart far greater strength to components. For composite fiber 3D printing, Markforged uses a combination of FFF printing and Continuous Fiber Fabrication (CFF) to deposit continuous fibers into conventionally printed thermoplastic parts. The continuous fiber is deposited into the part via a second nozzle in the print head. The fiber has only one starting point and one end point per layer.

Thanks to this fiber reinforcement, exorbitant strengths can now be achieved. Strengths higher than aluminum!

That's why we ask you directly: Are you still milling or are you already printing?

Shown here in the video is a Kevlar® continuous filament.

Request a DEMO component now!

See the strength of the continuous filaments for yourself.

In the video on the right, the huge added value of continuous filament is explained very simply and clearly using building blocks.

This technology is also based on extrusion and is "printed" via a second nozzle on the print head. However, instead of melting the entire filament, the heat from the nozzle is used to "iron" fibers into a thermoplastic layer. The actual fibers do not melt - instead they are captured by the thermoplastic matrix in a similar way to thermoset adhesives (e.g. epoxy fibers in conventional fiber manufacturing processes). This ensures maximum stability through optimal fiber design, because a firm bond is created between the continuous fiber and the matrix material.

The resulting parts are significantly stronger, stiffer and more durable than plastic (filled or unfilled) and retain the heat resistance, chemical resistance and print quality of their thermoplastic matrix material. With Markforged, you can print Onyx with continuous fiber reinforcement. Onyx is the base material consisting of Nylon/PA6 with 15 % micro carbon fiber content.

More and more companies are turning to carbon fiber composites to produce industrial-quality parts quickly and cost-effectively. For years, a compromise between strength, delivery time and cost had to be accepted. Conventional polymers could be produced quickly and cost-effectively, but the resulting components lacked considerable strength.

Onyx, nylon and fiber-reinforced plastics such as carbon fiber, Kevlar and glass fiber are available as printing materials for the Markforged 3D printers. These fiber reinforcements are printed into the component as continuous fibers. The diagram on the right shows the strength, robustness, rigidity and environmental resistance of the plastics in comparison with aluminum.

How to design your component optimally and how to optimize your Reinforce Z-axisyou will find here (Link).

Guide to 3D printing in industrial manufacturing

3D printing has become a powerful force in today's manufacturing industry, from prototyping to tooling and fixtures to low-volume final production. Many companies struggle to find the right additive manufacturing solutions that fit their exact needs and provide a return on investment (ROI). Choosing the right platform to prevent manufacturing blockages is critical to optimizing the productivity of your production line. Download this guide to assess the key considerations when choosing a 3D printer for manufacturing applications.

You will also find the following points in this 19-page guide:

To contact us, please fill out our secure form.

World-leading companies use Markforged 3D printers