In the production of electronic components, FESTO relies on the

3D printing with Markforged

The company

With more than 20,000 employees in over 60 countries, the FESTO a leading global supplier of automation technology. The company stands for innovative products, excellent quality and the provision of solutions for complex automation technology and technical education. Technologiefabrik Scharnhausen is Festo's leading plant for valves, valve terminals and electronics.

High demand for individual operating resources

The FESTO technology factory in Scharnhausen, south of Stuttgart, has been a leading plant for the production of valves, valve terminals and electronic components since 2014. When you enter the production facility, you immediately notice the extensive scale of the production systems and the highly developed automation and process optimization.

The use of high-tech machines and systems requires a wide range of individual operating resources, such as spare parts, individual parts and devices, in order to minimize unplanned downtimes and maintain production efficiency. By using high-quality spare parts and equipment, FESTO can also guarantee high production quality and customer satisfaction.

At a glance

ESD requirements posed a challenge

Stefan Fent (Head of Equipment Design) and his team wanted a solution that went beyond simple 3D printing.

The aim was to minimize the high costs and the high expenditure for the various operating resources.

They were looking for a genuine manufacturing system that could produce mechanically resilient components with process reliability and repeatability.

The focus was particularly on the substitution of plastic and aluminum components, which previously had to be ordered with long lead times or manufactured mechanically.

In addition, the system had to be able to reliably manufacture applications for electronic component production with ESD-compliant materials.

An initial attempt to integrate 3D printing into workflows failed precisely because of the latter requirements. This is because there are many 3D printers, but only a few that reliably meet the requirements of the industry.

Industrial 3D printing from a single source

The team got to know Markforged's additive manufacturing machines at a regional trade fair. By using continuous fiber technology, the issue of mechanical strength was quickly resolved. With the continuous carbon fiber, the strengths of aluminum can even be surpassed.

At Markforged, software, hardware and materials go hand in hand. The eco-system is 100 % coordinated with each other and thus offers maximum reliability and process safety.

The Markforged material Onyx ESD also meets the antistatic requirements of the EMS industry.

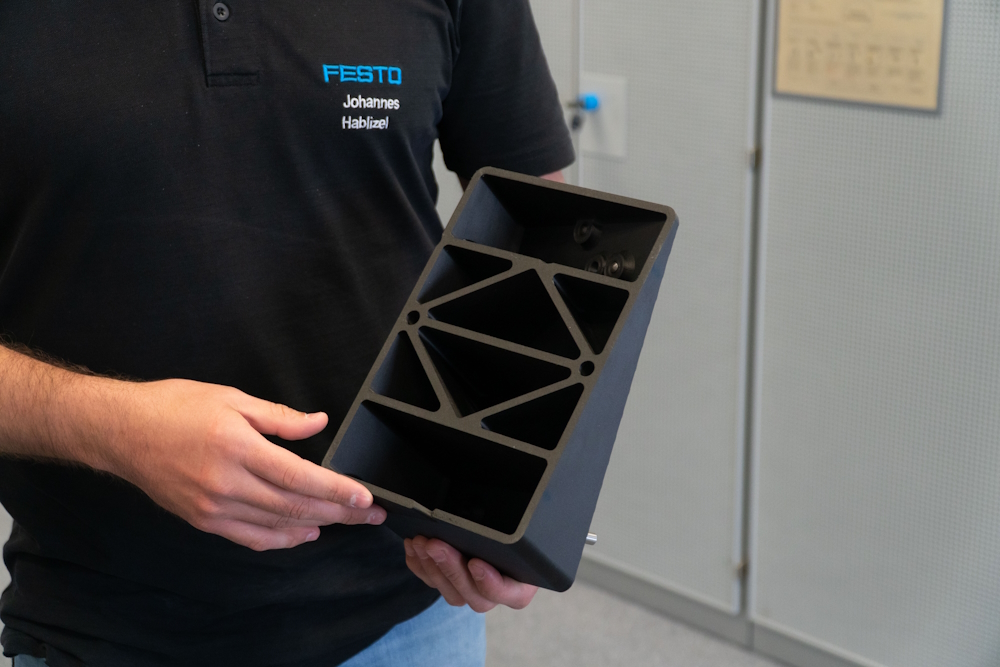

In spring 2022, Stefan Fent decided to integrate two production machines from Mark3D - Markforged into the production equipment department. Since then, a Markforged Onyx Pro and a Markforged X7 have been producing jigs and templates around the clock. The Onyx Pro is a desktop machine and all-rounder for the production of continuous fiberglass-reinforced components.

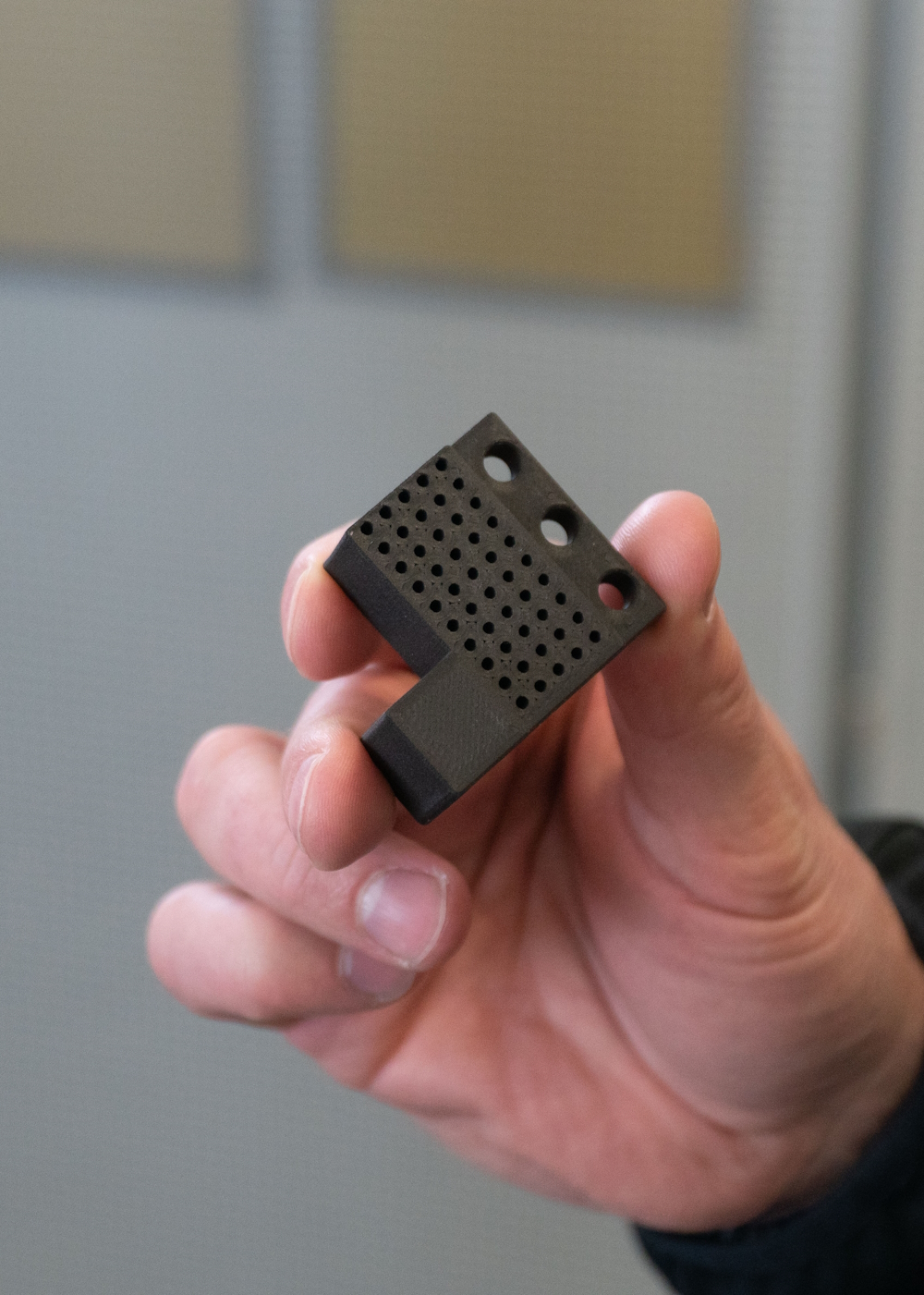

The Markforged X7 produces mechanically resilient components by inserting the continuous fibers carbon, glass fiber and Kevlar into the components. It can also be used to print components for electronics production in Onyx ESD material.

Request a DEMO component now!

See for yourself how strong the components are.

The learning curve in the team grows quickly

It took about 2-3 months for the designers to start integrating 3D printing into the production of equipment.

Today, nine months later, the printers are already booked for several weeks in advance. The learning curve in the team is growing exorbitantly.

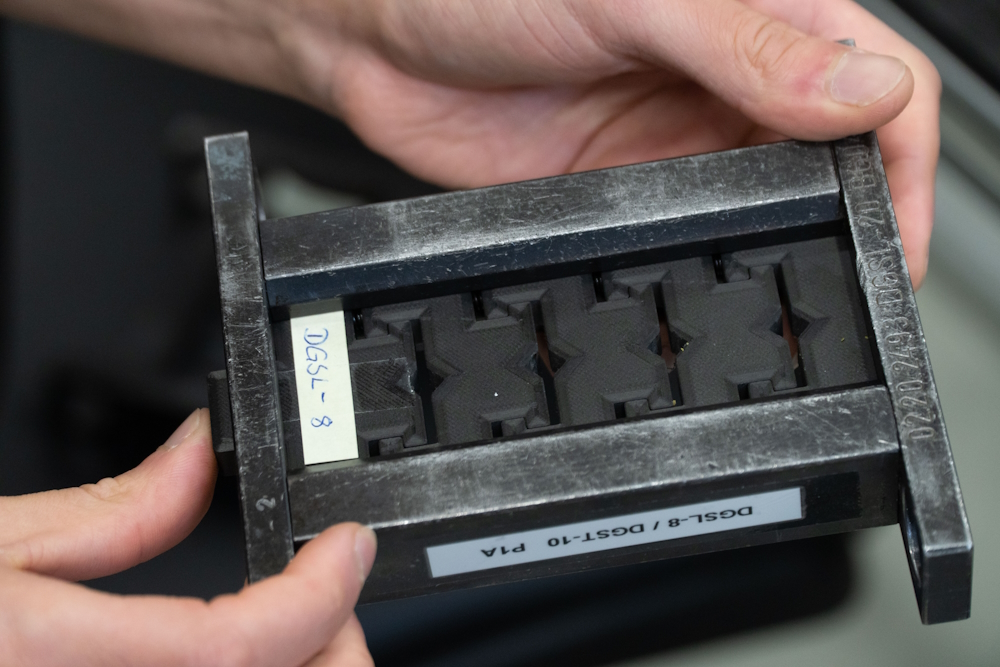

The production machines are operated by several employees in the company. The additively manufactured components, whether large or small, can be found in many places in production. These include sensor holders, housings, handles, clamping and holding devices, tools, templates and spare parts.

FESTO has already additively manufactured well over 200 different components that would otherwise have to be laboriously milled or ordered.

A shared database provides an overview of upcoming print jobs, costs and savings and helps to ensure that jobs are processed efficiently.

Additive manufacturing is now an established manufacturing technology for the FESTO team in Scharnhausen.

Over 80,000 euros saved in nine months

The order database also lists the savings made on all previously printed components.

Due to the strong growth in demand from various departments, the equipment design team managed to save around 80,000 euros in nine months.

"Markforged is a genuine manufacturing system. The quality and strength of the components as well as the reliability convinced us."

- Johannes Hablizel, Design Engineer Equipment Construction, FESTO SE & Co. KG

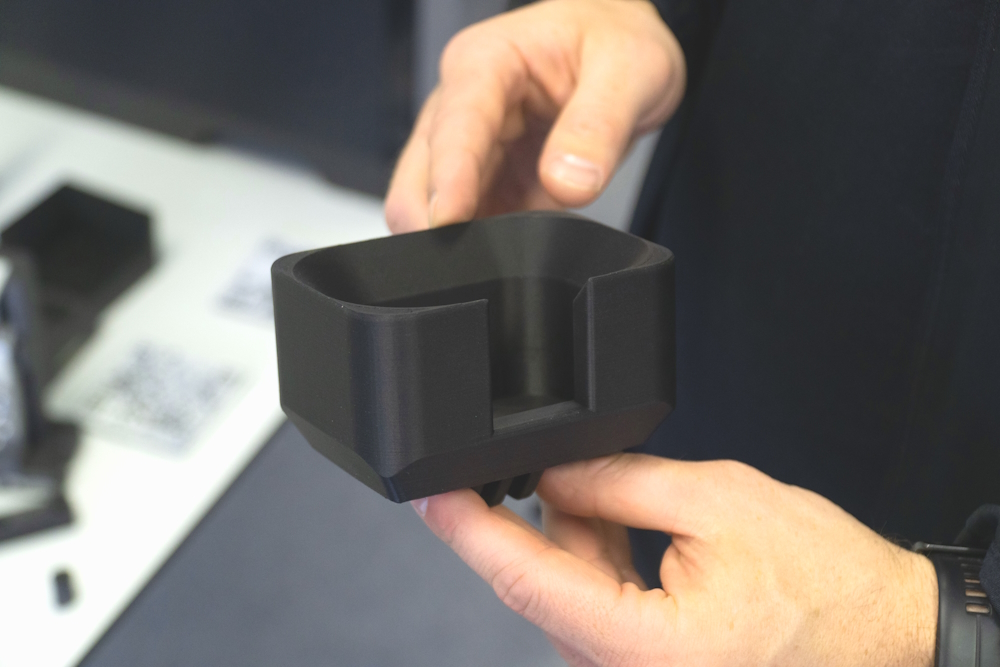

Practical example of holders for hand-held scanners made of ESD

One example that illustrates the cost reduction is a simple, three-part holder for a hand-held scanner.

With a planned mechanical production, the costs for 10 pieces were estimated at around 4,000 euros. Using 3D printing, the cost of the bracket made from the Onyx ESD material is just 385.88 euros plus 200 euros in labor costs. In total, a saving of 3,414.12 euros was achieved compared to mechanical production.

Used where it makes sense, 3D printing offers enormous added value for every company.

The Digital Forge

When you look at the printed components at FESTO, you quickly notice that each individual component has a serial number or component identifier.

If a component or part of an assembly is damaged or worn, a replacement part can be reprinted.

With the dynamic additive manufacturing software Eiger from Markforged, any part can be manufactured on-demand at any production site in the world.

Selected employees have access to the data and can dispose of it.

The future

Initially, the current capacity utilization of the 3D printers is to be maintained. If this increases further, the company will consider expanding its portfolio.

Furthermore, the potential of the new Markforged FX20 industrial 3D printer is currently being examined to decide whether it can be used in production. With its increased capacity and the ability to produce even larger components, the FX20 could be another success story for FESTO.

FESTO equipment designer Johannes Hablizel and project assistant Giuseppe Calì with the Markforged Onyx Pro and X7.

©Festo SE & Co. KG, all rights reserved

Would you like a live demo, have questions or need a quote for a Markforged 3D printer?

Contact us now!

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.