By using 3D printing, Garry Rogers Motorsport was able to save $300,000.

The customer

Garry Rogers Motorsport is Australia's oldest motorsport team, with victories in the National Supercars Championship, the Dunlop Super2 Series and the Bathurst 1000. The company has a team of almost 40 employees and focuses on the development, construction and maintenance of its own vehicles.

The challenge

While the in-house workshop can do some manual machining and composite fabrication, it does not have CNC machining capabilities. Instead, the team turned to third parties every time they needed multiple complex parts in small batches, but the turnaround time wasn't fast enough and the cost was too high. The more time spent outsourcing parts, the slower the research and development process became - which meant the team had less time to focus on improving the performance of its cars, both on the track and in the pits during pit stops.

The engineers and designers at Garry Rogers Motorsport use CFD (Computational Fluid Dynamics) software to test the airflow of their parts. The software often recommends changes to a part's design to increase speed and improve overall performance, which can result in extremely complex parts - something the team can't produce using any other method. This challenge, combined with the high costs and long lead times associated with adding additional details to a part's design, made engineers and designers reluctant to iterate on parts that require complex designs.

Request a DEMO component now!

See for yourself how strong the components are.

"3D printing offers us another way to produce parts that would normally be too expensive."

- Stefan Millard, Team Manager, Gary Rogers Motorsport

At a glance

The solution

In 2013, Stefan Millard, Team Principal at Garry Rogers Motorsport, made the decision to add a 3D printer to the workshop to provide engineers and designers with a new and complementary way to produce prototypes and production parts. During his research, he learned of a new machine capable of 3D printing parts from carbon fiber, a material the team was familiar with. "It seemed like Markforged was the only company that focused on making strong end-use parts, not just prototypes," he recalls. The team needed carbon fiber to make strong parts for their race cars - and these needed to withstand heavy use. Stefan ordered a Markforged 3D printer a few months later, making Garry Rogers Motorsport one of the first companies in Australia to invest in Markforged technology.

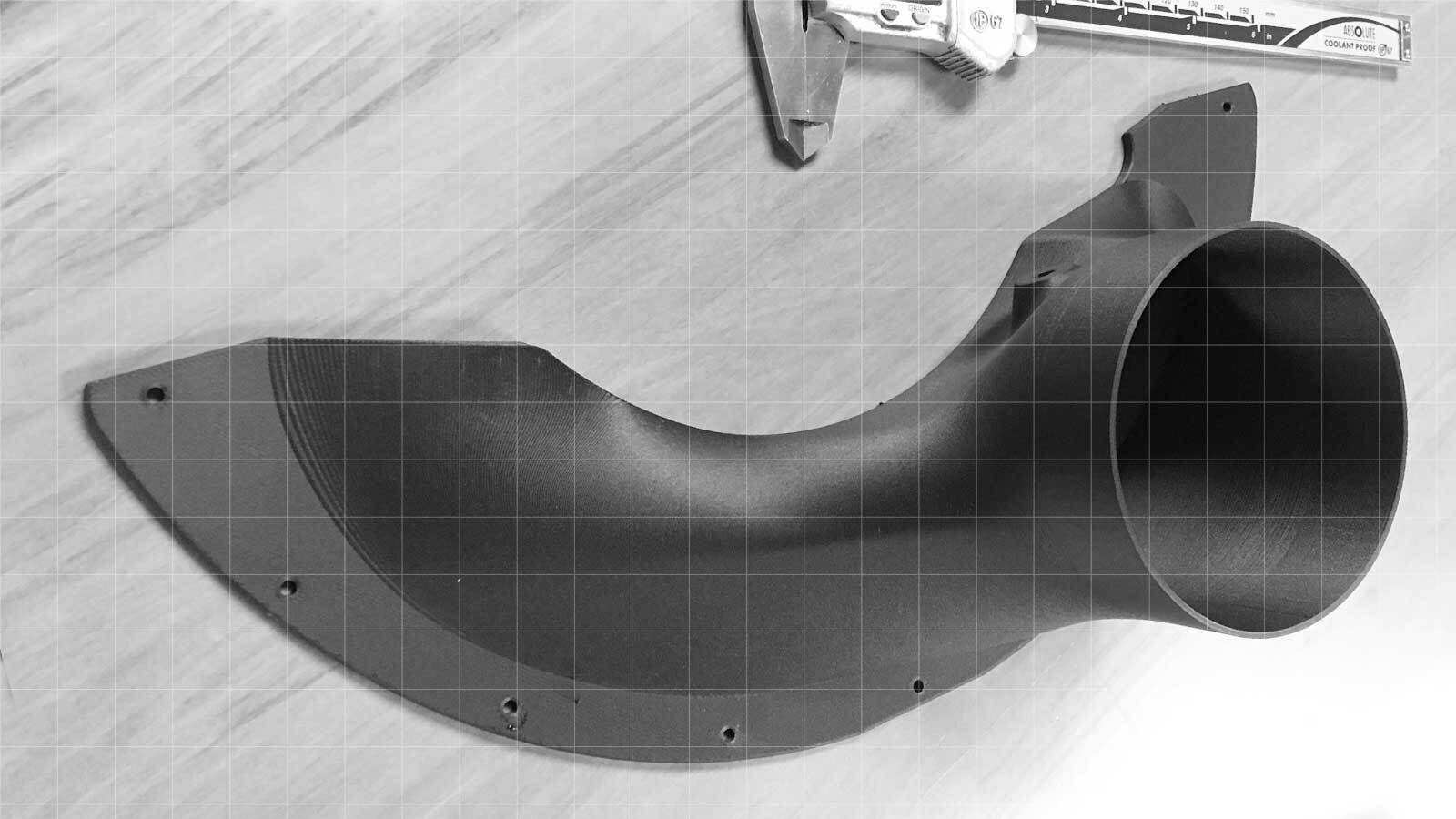

Today, the Garry Rogers Motorsport team mainly uses its 3D printer to print complex parts - from jigs and fixtures to final parts for race cars. According to Stefan, about half or more of the parts produced are for end-use, based on suggestions from the CFD software. End-use parts include covers for door locks, gearbox housings, steering wheel handles and camera mounts for the drivers. "We tried to print everything possible," says Stefan. However, the team has had the most success printing patterns for molded fiberglass parts. A recent example of this was a pattern for a brake duct - a part used to make a mold for the final brake duct - which used to cost AUD 1,000 (~USD 670) and took two weeks to produce. The team printed the same part in-house for 75 AUD (~50 USD) and reduced the turnaround time to 24 hours. The brake duct sample also includes details in its design that cannot be easily produced using subtractive methods - and unlike a CNC machine, a 3D printer does not charge extra cost or time due to details in a design.

"The ability to print stable parts for the end application is the biggest selling point for me. It's a really reliable printer."

- Stefan Millard, Team Manager, Garry Rogers Motorsport

The future

According to Stefan, the two biggest benefits of the investment are the flexibility of the design and the reduction in lead time. This in turn has helped the team to increase the performance of their cars. Since purchasing the carbon fiber 3D printer, the focus has been on reducing assembly time by printing parts that previously had to be assembled as one part. The time saved by using Markforged technology is reinvested in research and development. "The extra time we gain by using our Markforged printer goes directly into designing or manufacturing more parts or looking at other areas to make Garry Rogers Motorsport cars faster - that's our main goal," says Stefan.

Would you like a live demo, have questions or need a quote for a Markforged 3D printer?

Contact us now!

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.