Development and Manufacturing

of Tools and Fixtures

Hockley Ltd specializes in the development and manufacture of composite tools, production tools, assembly tools, fixtures, and a wide range of similar products.

Founded in 1979, the company has in-depth expertise in the manufacture of composite materials and a dedicated tooling solutions department. Hockley Ltd is known for delivering customer solutions that truly meet customer needs.

Challenge

Keeping pace with modern technology is a full-time job:

The key is innovative solutions for a demanding market. Ian Eaves is responsible for new manufacturing technologies. Management is forward-thinking and has made strategic investments over the past 18 months. “We have a commitment to our customers to deliver the right solutions quickly and cost-effectively. We invested in 3D printing to see if the technology was ready for engineers,” explains Ian Eaves, adding: “We wanted to expand our design and production capabilities by introducing additive manufacturing technology. Our goal is to better serve existing markets and tap into new ones.”

Hockley Pattern has truly skilled engineers, which is why it’s essential that they have access to the necessary technologies to help them realize their ideas. 3D printing is a fast and cost-effective way to do this. We can now offer solutions to the technical challenges we face in a very short time – previously, we had to wait a long time for machine capacity to be made available to us. Furthermore, we wanted to use additive manufacturing technology to produce small batches faster and more efficiently. If we could find a machine that would allow us to print high-quality parts that are consistently durable and reliable, that would be a huge bonus!

"When we discovered the properties of Onyx combined with the added value of continuous carbon fiber, we immediately realized the positive impact this would have."

Solution

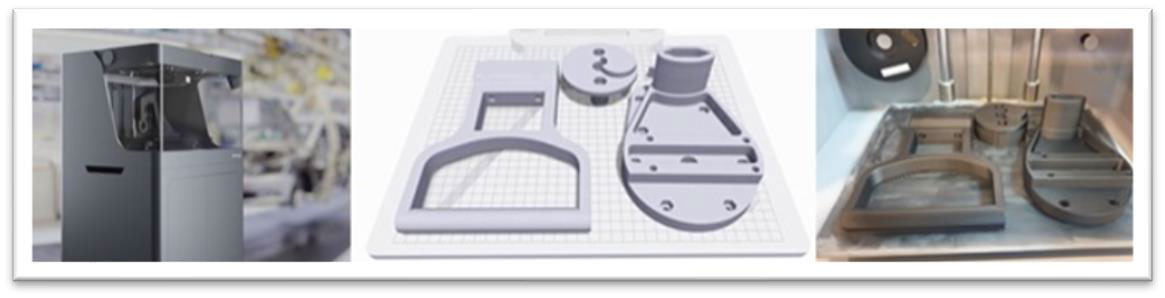

Markforged 3D printers from Mark3D:

Ian Eaves visited the Mark3D technology center and discovered the significant added value of the technology. “I had already explored 3D printing and was fascinated by the possibilities,” says Ian. “However, I wasn’t familiar with Markforged technology at all. I wanted to learn more.”

During his visit to Mark3D, Ian Eaves took the time to learn all about the various materials, continuous fibers, and other technologies, and to discover their benefits for Hockley Pattern. A subsequent demonstration of Markforged technology for other members of his team led to the decision to invest in a Markforged X-Series 3D printer, the “X7.”

At a glance

“Our recent investment in a large industrial 3D printer, with exceptional accuracy and reliability, has already yielded great results. This is all supported by the training and certification of our engineers to find further applications.”

– Ian Eaves, Group Technology Leader

“It was great working with Mark3D. They communicate clearly and helped us implement the technology quickly.”

– Lee Evans, Project Manager

“It’s great to work with a company that understands what we’re about and with whom you can have a collaborative discussion!”

– Lee Evans, Project Manager

Request a DEMO component now!

See for yourself how strong the components are.

Markforged University

The Hockley Pattern team invested not only in a 3D printer but also in the training and development of its employees.

Hockley's project manager, Lee Evans, visited Markforged's headquarters in Boston to participate in Markforged's training courses to maximize the benefits of the technology. Now a Markforged-certified AM user, Lee advises customers on the effective use of the technology.

"The Markforged University program opened my eyes to the opportunities that additive manufacturing technology offers," Lee explains enthusiastically. "I learned all about designing for AM, how to select the best materials for the application, and how to maintain our machine. I also saw the impressive Metal X Metal 3D printer in action."

Initial Work

Precise coolant delivery is essential to maintain the cutting edge's lifespan.

“One of our long-standing customers asked us to help with a component subject to repetitive stress. The challenge was to reduce the weight without compromising stability. We accepted the challenge and optimized the component's design. We were able to reduce the weight by 40%. The 3D-printed parts have an excellent surface finish and no loss of stability. The customer's sales team is thrilled with our working prototype.”

Next Steps

What's next for Hockley?

So far, Hockley has 3D printed a wide variety of components, such as fixtures, jigs, and tooling solutions. But they are ambitious to also offer 3D-printed solutions for integrated manufacturing processes. With the X7 3D printer, Hockley can tap into new markets. The machine can print the new Onyx FR material (fire-rated), which undoubtedly opens up new possibilities for defense, aerospace, automotive, and nuclear applications. Of course, there is also the option of 3D printing parts for electronic assemblies using Onyx ESD.

Furthermore, Hockley will be exploring coatings. Lee Evans emphasizes: "Onyx prints very well and has a great surface finish. It's so stable and strong that we've decided to find further applications. I'll be visiting one of our coating partners and conducting tests. We've already had relevant use cases in the past."

The plan is to further expand the additive manufacturing (AM) business. Management has already signaled its intention to invest further. To quote Ian Eaves: “Standing still is falling behind. At Hockley, we are constantly working to improve. New technologies are a key factor in helping us do that.”

Learn more about 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.