How 3D-printed spare parts are revolutionizing a print shop

The company

Founded in 1891, Vogel Druck und Medienservice GmbH is one of the leading web offset and media service providers in Germany with 350 employees and sees itself as an innovative system supplier with a high level of vertical integration. The company is part of the Bertelsmann Marketing Services and specializes in the production of magazines and catalogs.

High costs for spare parts lead to research

Like many other sectors, the printing industry is also facing major challenges. Digitization and rising prices for paper and materials require ever more cost-efficient working methods.

Jörg Kuchenmeister, Managing Director of Vogel Druck und Medienservice, has witnessed numerous developments in the industry over the past 20 years. The company has always responded to these changes with innovations. For example, the company has been completely climate-neutral since last year.

One negative development is the enormous cost of spare parts for older machines. Exorbitant prices for simple wear parts that quickly run into hundreds of thousands of euros. To counteract the enormous costs, Jörg Kuchenmeister saw a possible solution in 3D printing.

At a glance

Getting started in additive manufacturing with a 3D printing service provider

It all started with a collaboration with a 3D printing service provider.

The first components were printed by this service provider on a Markforged 3D printer and the tests were promising.

However, the process was not dynamic enough for Jörg Kuchenmeister. He wanted to move from planning to doing and build up the expertise in his own company.

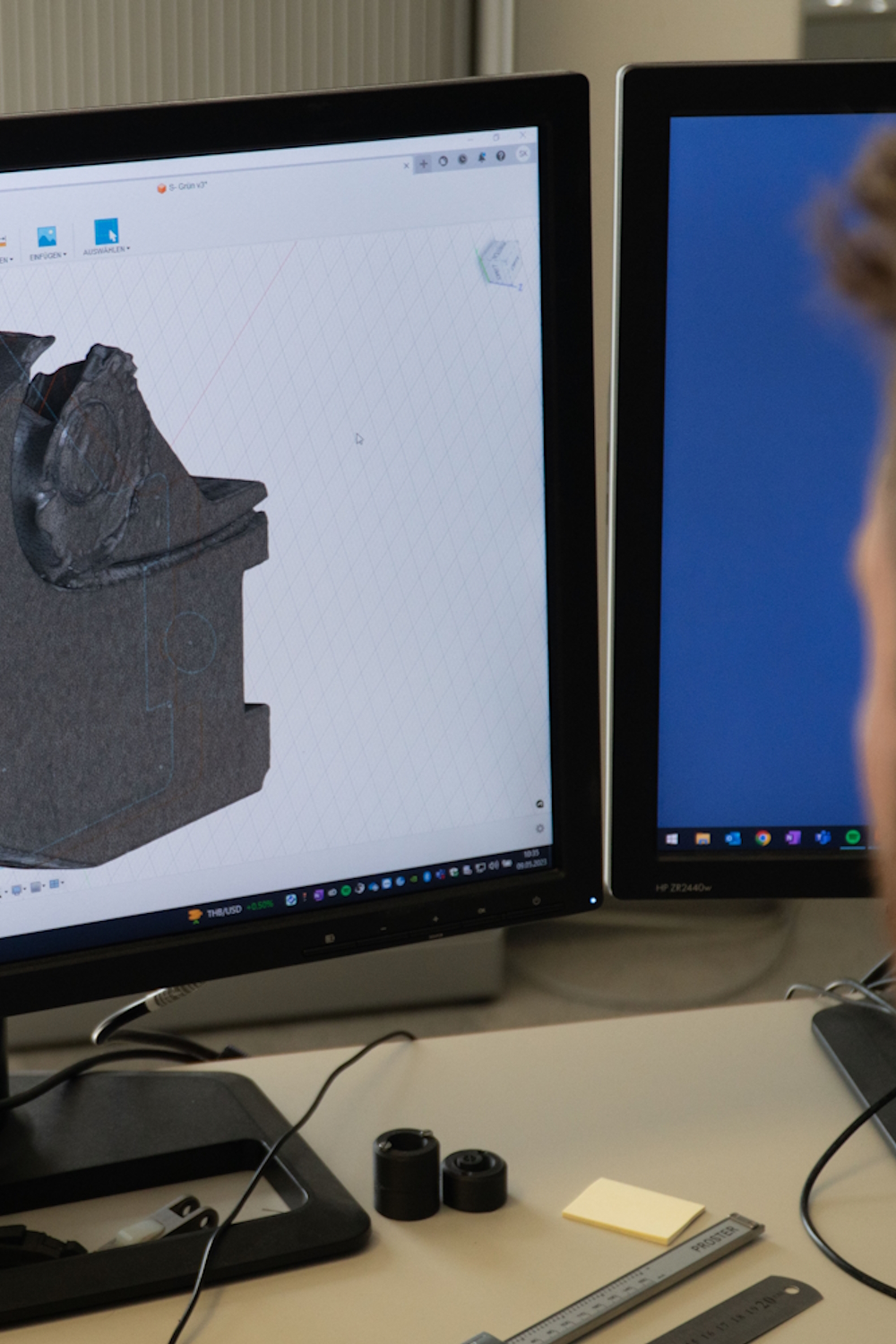

As part of Formnext 2021, a Markforged Mark Two is purchased and Stefan Kemmer, responsible for quality assurance, also becomes a 3D printing officer. He learns how to design in CAD automatically and starts a success story together with the entire team.

Initial successes inspire confidence in the new technology

The coherent system of material, software and hardware made it easier to get started with the new technology. However, the operating technicians at Vogel Druck und Medienservice were initially somewhat skeptical about the new technology, but quickly came to appreciate its added value.

Around three weeks after purchasing the Markforged Mark Two 3D printer, the first acute case arose in production that prompted a rethink. Shortly after the start of the shift, a part broke in a machine. Production came to a standstill. The delivery time for the replacement part from the supplier was six to eight weeks. The operating technician sought help from Stefan Kemmer. He saw the solution in the new Markforged 3D printer. Without further ado, he designed the component in Fusion 360 and sent it to the printer. After just four hours, the plant technician had the freshly 3D-printed spare part in his hands. The spare part was installed in the same shift and the machine was up and running again.

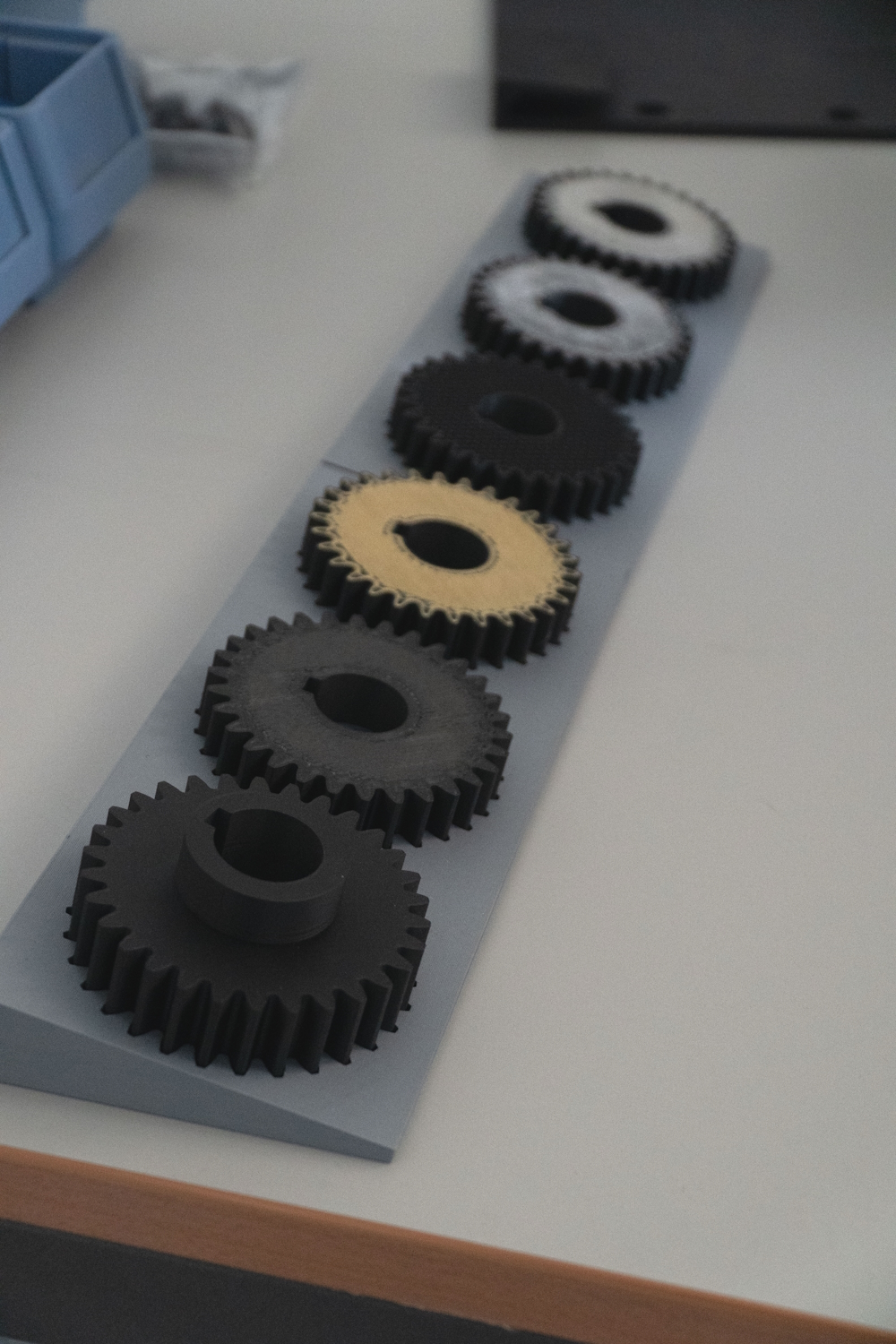

This was followed by other parts on the machines and units that could be replaced quickly without having to dismantle the machine. Machine parts made of POM material are particularly suitable, but in some cases aluminum or steel parts are also suitable. The components were designed and printed in a very short time. The utilization of the 3D printer continued to increase.

Two areas are covered by industrial 3D printing:

- Machine spare parts

- Improvements such as fixtures or brackets

A spare part amortizes the 3D printer

Utilization of the Markforged 3D printer continues to increase. Numerous machine parts are being replaced. A "finger" in a machine often breaks off. Costs around EUR 450, depending on the daily rate. The printed "finger" costs EUR 3.50. With around 30 to 40 of these "fingers" per year, around EUR 20,000 was saved in a very short time.

As a result of the high capacity utilization, the company quickly invested in another Markforged Mark Two.

Savings of over EUR 80,000 after nine months

All savings are documented in a list. Jörg Kuchenmeister proudly calls it the "celebration list". This list proves that industrial 3D printing is not only an exciting technology, but also delivers real added value for the company. After nine months, both printers have achieved savings of around EUR 82,000. Small parts - big parts. And there is no end in sight.

Another side effect is the possibility of using hard-to-find and discontinued spare parts. This means that machine running times can be extended or units can be put back into operation more quickly.

Thanks to the additive manufacturing of spare parts and auxiliary materials, it was possible to increase running performance by up to 20 %, depending on the product, by using the machine optimizations. Savings of more than 90% on spare parts and faster makeready times are an additional major added value for Vogel Druck und Medienservice.

"There is no way around Mark3D - Markforged. It is the most coherent system on the market. We have received a complete solution in the field of 3D printing. We can fully focus on our core business and utilize the added value of the technology."

- Jörg Kuchenmeister, Managing Director, Vogel Druck und Medienservice GmbH

The future

The current status is to be maintained for the time being. Further components will be substituted and costs will continue to be saved. Depending on capacity utilization, an investment in another Markforged 3D printer is not ruled out.

A partner company from the USA has also already decided to invest in a Markforged 3D printer. This means that the possibilities of Markforged technology can also be used profitably in the USA and experience can be shared across locations. Jörg Kuchenmeister is confident about the future.

Would you like a live demo, have questions or need a quote for a Markforged 3D printer?

Contact us now!

![]() Mark3D GmbH

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.