KST Moschkau minimizes production costs to a sixth with the Markforged FX20

The company

When demand for a new product exceeded expectations, security systems manufacturer KST Moschkau chose the Markforged FX20 to bypass complex supply chains with scalable production.

The result? The FX20 reduced lead times from 3-4 weeks to 2 days. Production costs are one-sixth compared to using multiple aluminum components from external CNC shops.

The customer

KST Moschkau GmbH is a family-run company founded in 1985. As a project system house, KST develops complex system solutions in the main business areas of broadcast & ProAV, media technology and AV security systems.

Within KST Moschkau, the System Construction division manufactures an extensive product portfolio of components, articles and systems in-house using state-of-the-art production techniques and has begun to expand its product portfolio to include out-of-the-box solutions for individual requirements.

The challenge

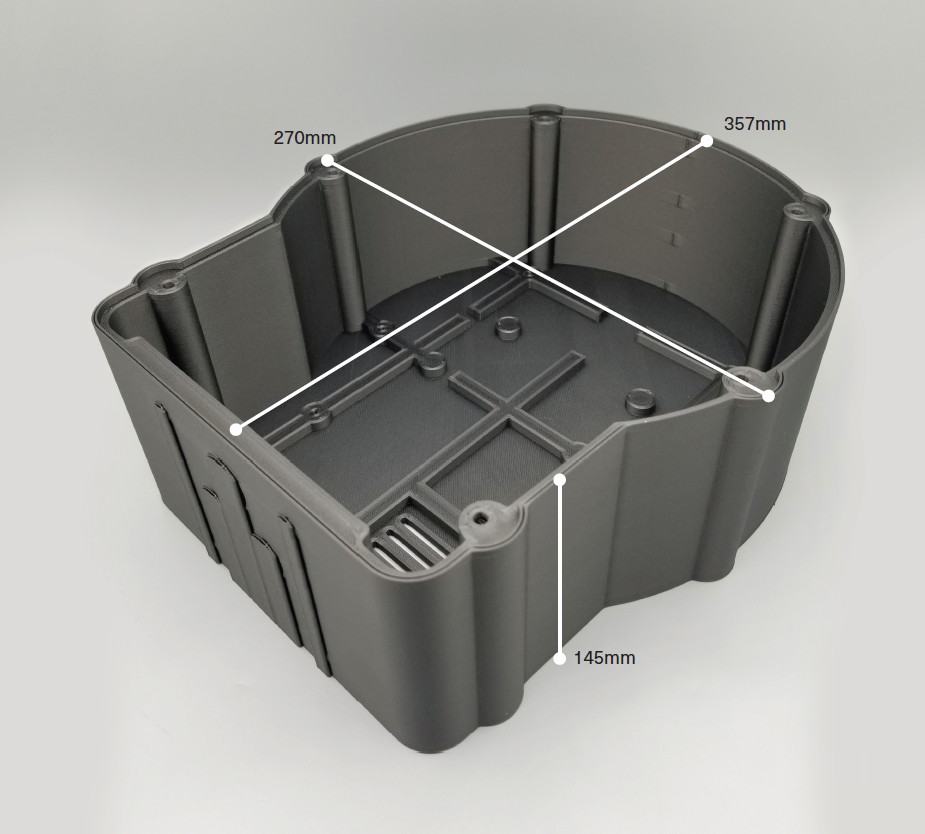

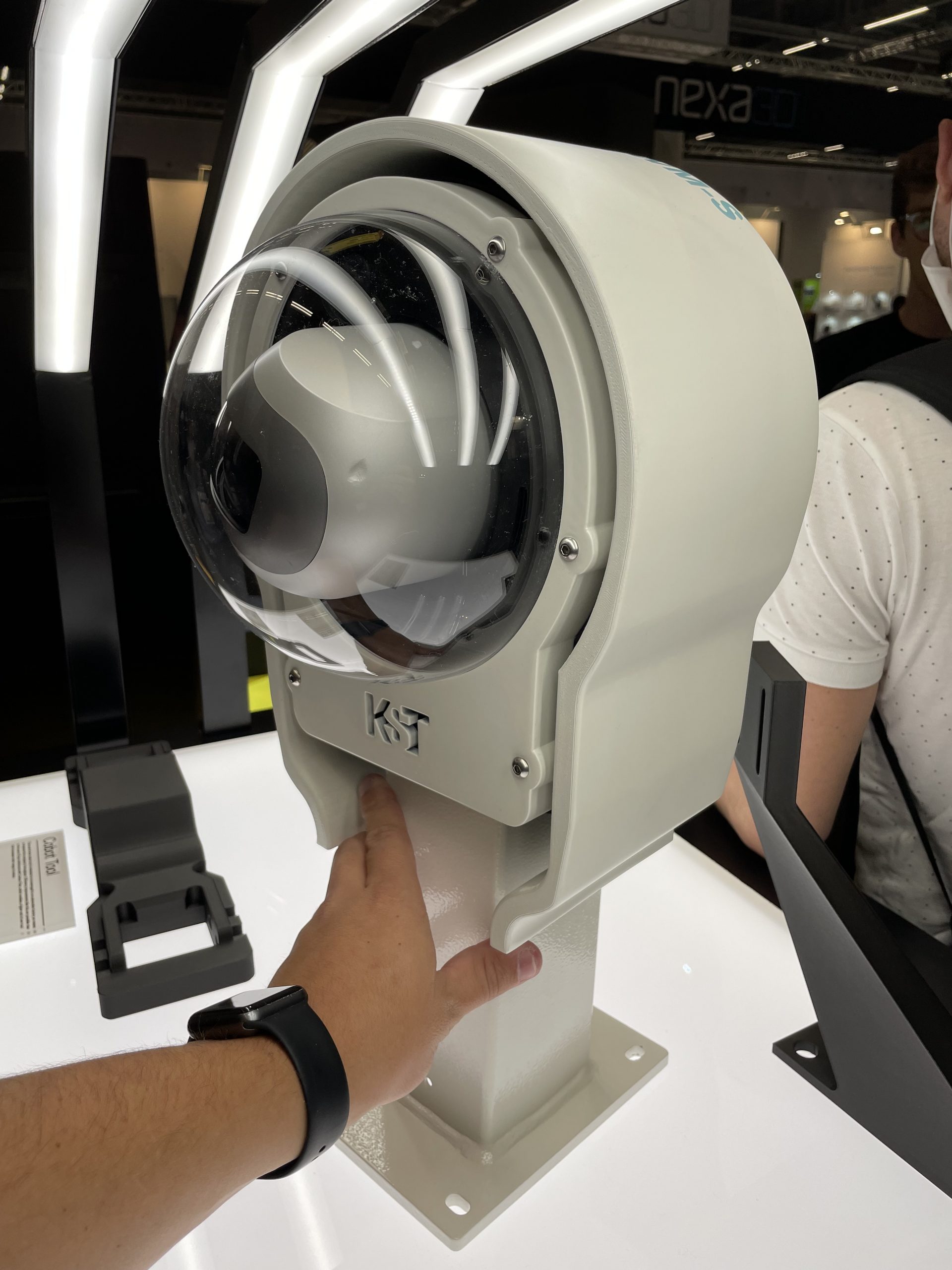

In early February 2020, KST began production of the KST-OH series, an outdoor housing for Panasonic's PTZ camera. Demand for the product exceeded the company's expectations, but it quickly became clear that the current manufacturing process was not scalable for low-volume production. Originally, the camera housing was designed in-house and the components were outsourced to specialist CNC companies for machining.

Since the housing is made up of multiple aluminum panels, the iterations to customize these small quantities quickly became expensive. The process became labor and time intensive - many steps were required to source and assemble the many components for a single product. In addition, the company had no control over delivery delays due to its reliance on third parties, further delaying projects for its customers.

Request a DEMO component now!

See for yourself how strong the components are.

"Switching to additive manufacturing immediately reduced costs and significantly accelerated production. We were given the flexibility to prototype and revise designs on our own terms before validation. The excellent surface finish and toughness of Onyx helped us meet the highest quality standards we set for our products."

- Felix Moschkau, KST Moschkau

At a glance

The solution

Instead of outsourcing the majority of their products to machine builders, the KST team took matters into their own hands. As a Markforged customer, the company immediately recognized the impact the FX20 could have on their supply chain. By using the FX20, KST was able to print 3 components on a single print bed - 525x400x400mm. On a smaller machine, they would have had to print fewer parts and split some of their larger designs into multiple parts.

Printing enclosures on the FX20 reduced costs and sped up production immensely, giving the company more flexibility to prototype and revise designs before shipping them to customers. The excellent surface finish and robustness of Onyx helped them to maintain the highest quality standard for their products. The housing was not visibly different from its aluminum counterpart after finishing. The only real difference was the slightly lower weight. This new manufacturing process ensures that the housing can withstand harsh outdoor weather conditions such as rain, UV rays and extreme temperature fluctuations.

Would you like a live demo, have questions or need a quote for a Markforged 3D printer?

Contact us now!

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

Global market leaders rely on Markforged 3D printers

To contact us, please fill out our secure form.