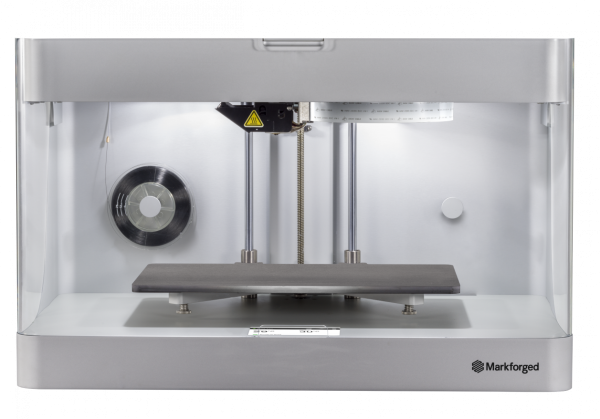

The Mark Two

Professional 3D printers for high-strength components with continuous carbon fiber

With the Markforged Mark Two 3D printer, you get a true all-rounder that allows you to produce highly stable components that you previously had to machine but didn't want to machine.

With the help of integrated continuous carbon fiber, you achieve the strength of aluminum while significantly reducing weight, offering design freedom, and at a fraction of the cost. This is manufacturing redefined!

The Markforged Mark Two was the world's first carbon fiber 3D printer and is the only printer in its industry that allows you to produce beautiful, high-end components for your manufacturing from digital CAD data.

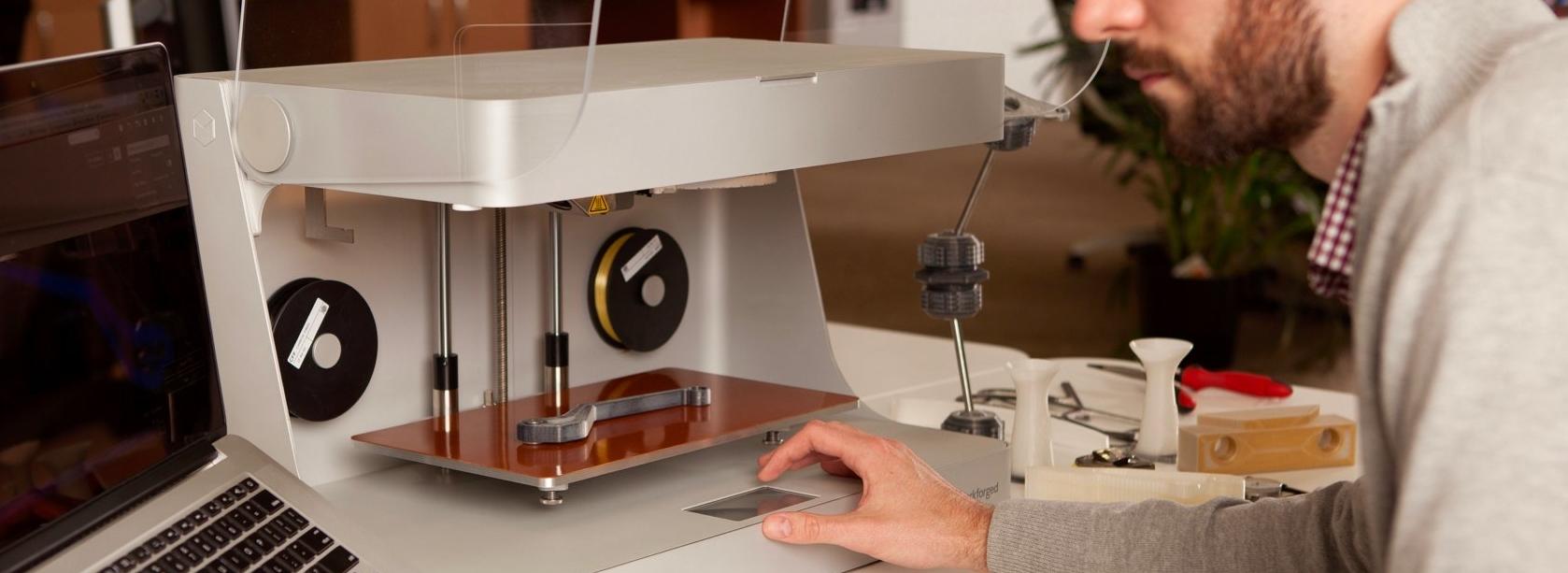

Small. But powerful.

Drive innovation. Right from your desk.

High-strength 3D printing

By reinforcing your components with composite fibers during 3D printing, the Mark Two achieves unparalleled strength, stiffness, and durability in its printed components.

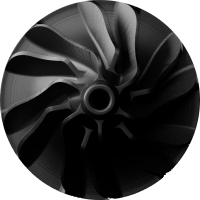

Precise and beautiful components

Print precise parts with premium surface finishes thanks to Onyx, the extremely versatile material. Onyx is a PA6 with short carbon fibers.

Easy to use

Markforged has developed its own 3D printing software, the EIGER software, which is included with every printer. Printing any part, whether flexible or rigid, is easy and intuitive.

Unparalleled versatility

The industrial 3D printers of the desktop series offer production-ready components as well as affordable prototypes – all on the same platform.

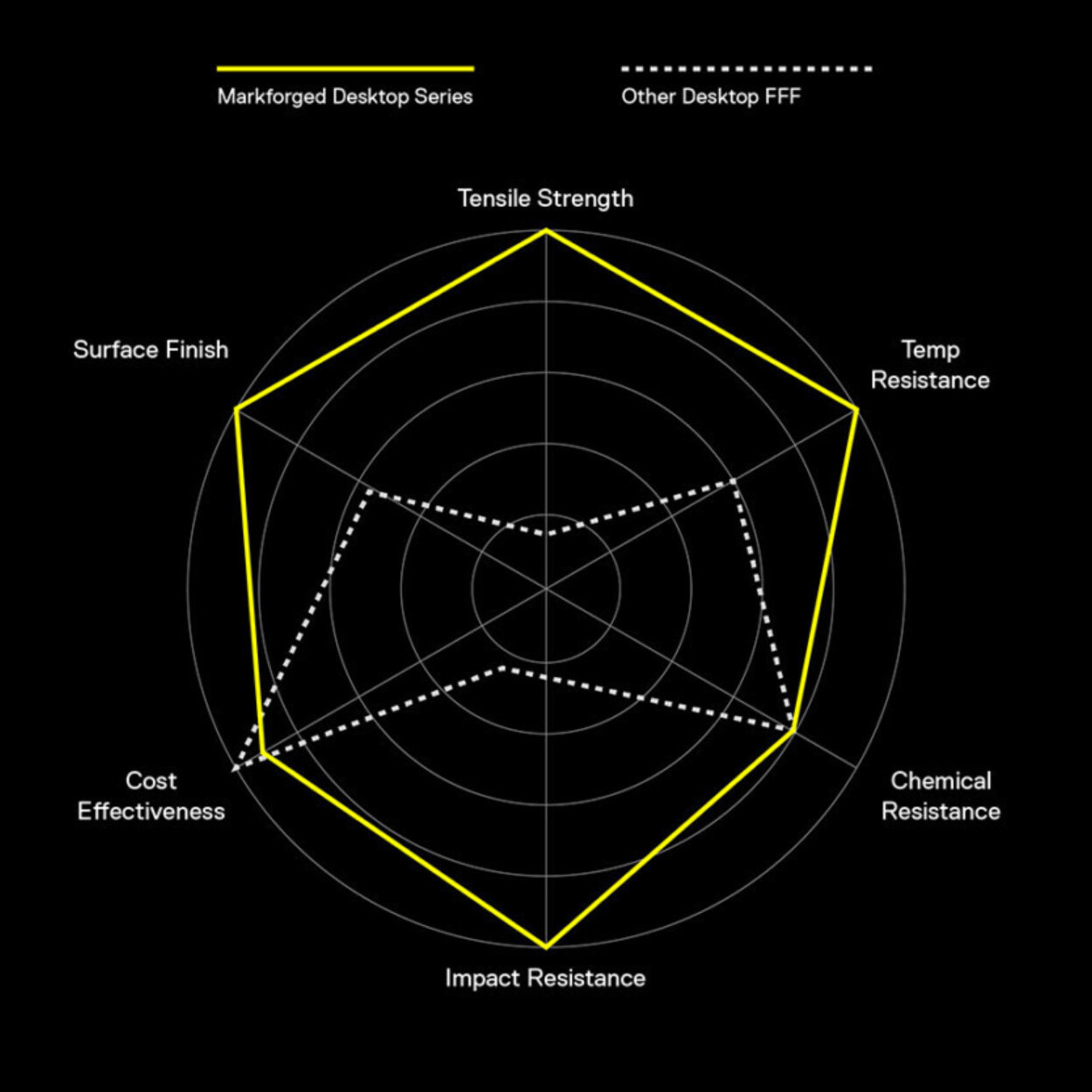

Our customers' favorite printing material is Onyx™. Onyx™ offers outstanding material properties and a superior surface finish. The unique selection of continuous fibers provides you with mechanically and thermally resilient components, far exceeding conventional FFF filaments.

While the Precise PLA delivers effective, reliable view samples and prototypes at an affordable price.

No matter what features you need for your applications, Markforged professional desktop printers have the right material for the job. The unibody aluminum housing and precision-engineered components ensure maximum reliability for thousands of printing hours.

Why continuous fibers?

Carbon fiber is only optimally designed to withstand tensile and compressive forces if the force acting on the component is applied in the direction of the fiber grain. If the carbon fiber is interrupted during the construction process, it can no longer absorb the optimal tensile and compressive forces. This is why the continuous fiber is so crucial for the stability of a component printed with carbon fiber, Kevlar®, or glass fiber. Continuous fiber-reinforced 3D printing thus ensures strength at a completely new level.

The technology: CFF

Continuous Filament Fabrication

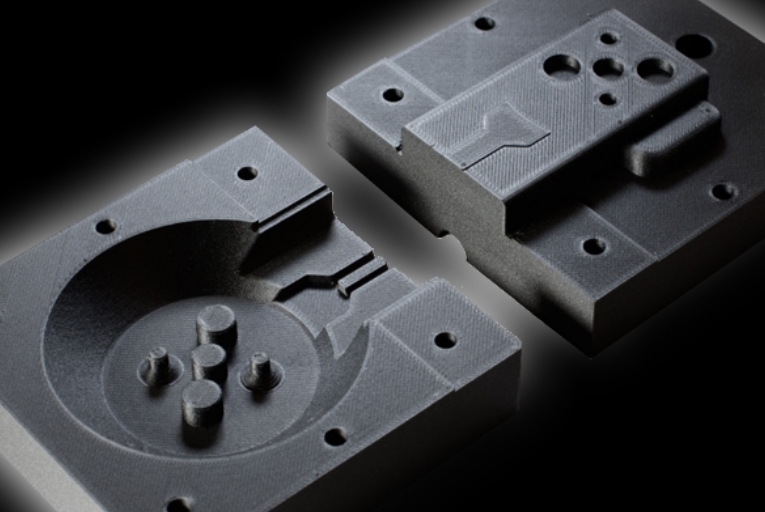

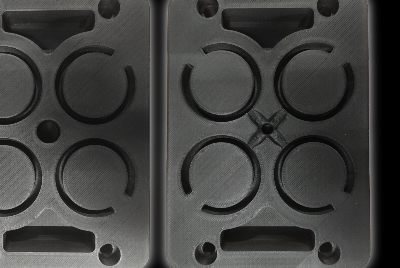

Fiber-reinforced components are made of two materials and are incredibly strong and versatile. Our unique manufacturing process allows you to print components that are much stiffer and stronger than typical 3D printed parts.

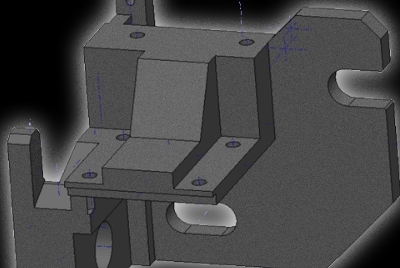

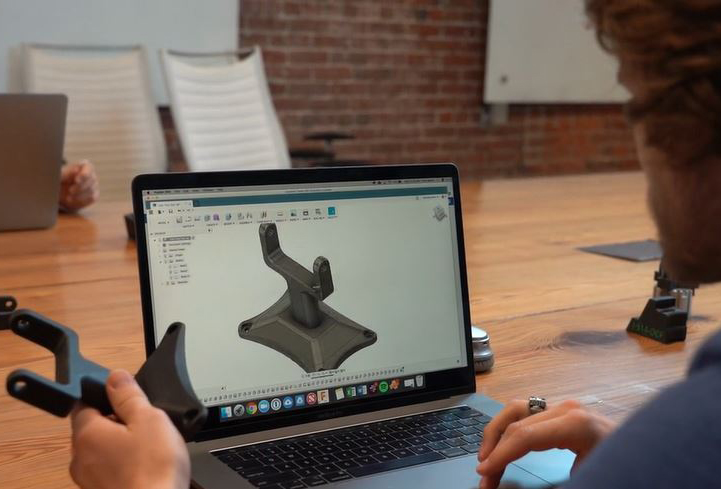

DESIGN

Create an STL file from your CAD model and load it into the EIGER software. Select the appropriate composite material, such as carbon, fiberglass, or Kevlar. The cloud-based software will do the rest, making it easy to print the right part.

STRENGTHEN

The dual material system produces the fiber-reinforced component layer by layer. The first nozzle forms the plastic matrix, and the second nozzle continuously deposits the composite fiber.

COMPONENT

Markforged CFF components are as strong as aircraft aluminum and over 40% lighter than machined metal tools, fixtures, and prototypes.

Touchscreen interface

The Mark Two features a built-in touchscreen that allows you to easily connect to Wi-Fi, start printing, and manage your printer.

Request a DEMO component now!

See for yourself how strong the components are.

Precision design

About the Mark Two

The Mark Two is the award-winning professional 3D printer for carbon fiber composites, based on the CFR (Continuous Fiber Reinforcement) process to produce reliably strong parts for you. It's built around an aluminum unibody frame, offering high accuracy and repeatability. A hardened extrusion system allows the Mark Two to reliably print Onyx—a polyamide filament filled with micro-carbon fibers (which, incidentally, destroys conventional extrusion systems)—for thousands of printing hours.

The machine is designed to be easy to operate and maintain – from easily accessible wear parts (such as nozzles and feed tubes) to user-friendly features such as the print bed, which can be replaced with a repeatability of 10 μm.

In addition to the standard FFF features, the Mark Two features a second-generation continuous fiber reinforcement system that allows you to insert continuous fibers into your parts. Only Markforged's industrial 3D printers, using composite technology, are capable of printing continuous fiber-reinforced parts with such high strength that they can replace machined aluminum components. This means you can print parts you previously had to machine but didn't want to. Are you still milling, or are you already printing?

Eiger Software

3D printing with composite fibers is as much about the software as it is the unique technology of the printers. The Markforged EIGER software is both powerful and easy to use in your browser. It imports your drawing and optimizes it for 3D printing.

Design your part, upload it to the browser-based Eiger software, choose from a wide range of composite or base materials, add a continuous fiber if needed, and click "Print." It's that simple.

Technical features

The most important information about the Markforged Mark Two carbon fiber 3D printer at a glance!

Designed to overcome the strength limitations of many 3D printing materials, the Mark Two 3D printer from Markforged is the world's first 3D printer to print composite materials. Now, functional parts, tools, and fixtures can be printed with a significantly improved strength-to-weight ratio.

| Construction volume | 320 mm x 152 mm x 154 mm* |

|---|---|

| Base material (filament) | onyx |

| Composite materials (filaments)

|

Carbon fiber Fiber optic Kevlar HSHT fiber optic |

| Z LAYER Resolution | 100 microns |

| Scope of delivery

|

Mark Two printer and cabinet with access to Cloud Eiger software 800 cc Onyx coil 100 cc carbon fiber spool 50 cc fiberglass spool 50 cc Kevlar coil 50 cc HSHT fiberglass spool 1 TrueBed print bed |

*When printing without continuous fiber, with continuous fiber the build volume is 320 x 132 x 154 mm

Would you like a demo, have questions or need a quote for a Marforged Mark Two desktop printer?

Contact us now!

Mark3D GmbH

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

To contact us, please fill out our secure form.