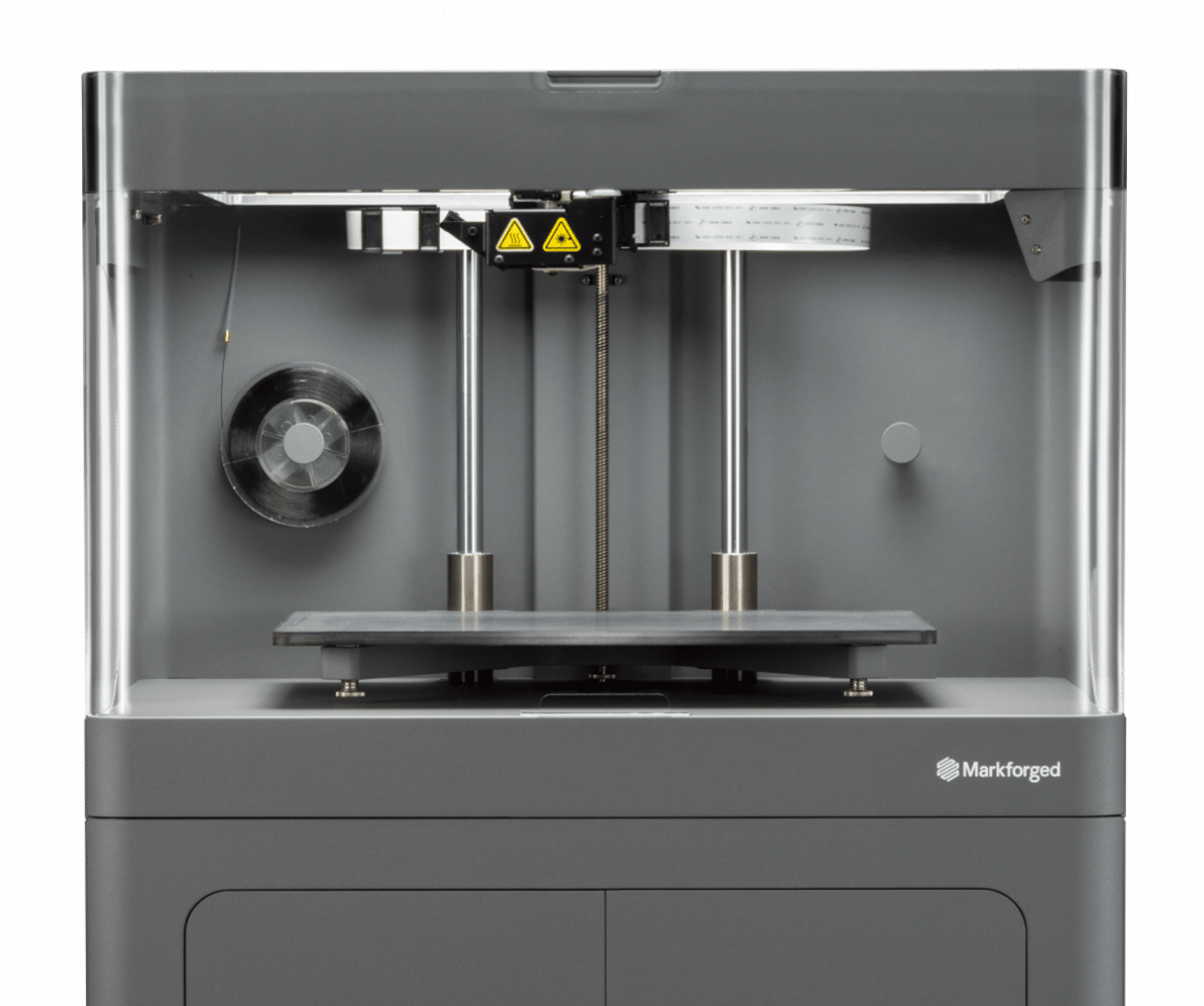

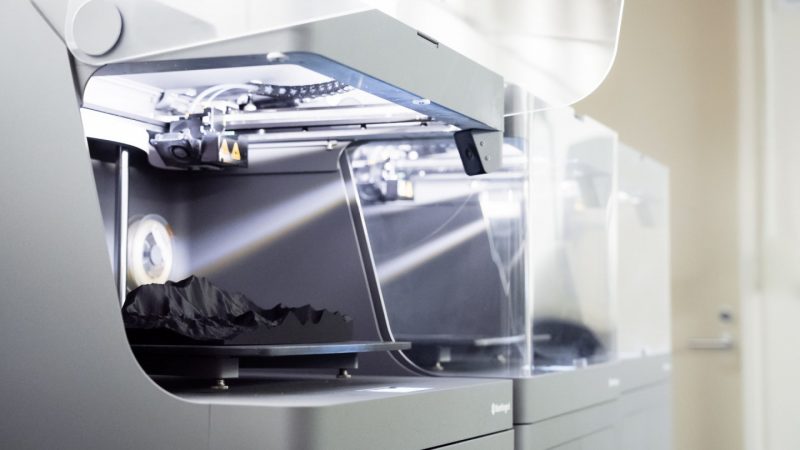

The Markforged X7

The industrial 3D printer for real functional components.

The Markforged X7 combines the advantages of Markforged's unique continuous fiber reinforcement, for components with higher strength than aluminum, with the excellent surface finish of Onyx. With the Markforged X7, you can turn virtually any design concept into reality.

In modern equipment and fixture construction, there's no way around industrial 3D printing with Markforged. This game-changer enables you to produce highly complex and precise components that previously required milling.

Large 3D printing, high-quality resolution

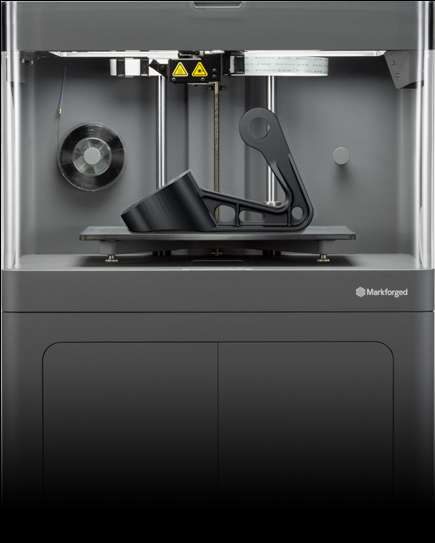

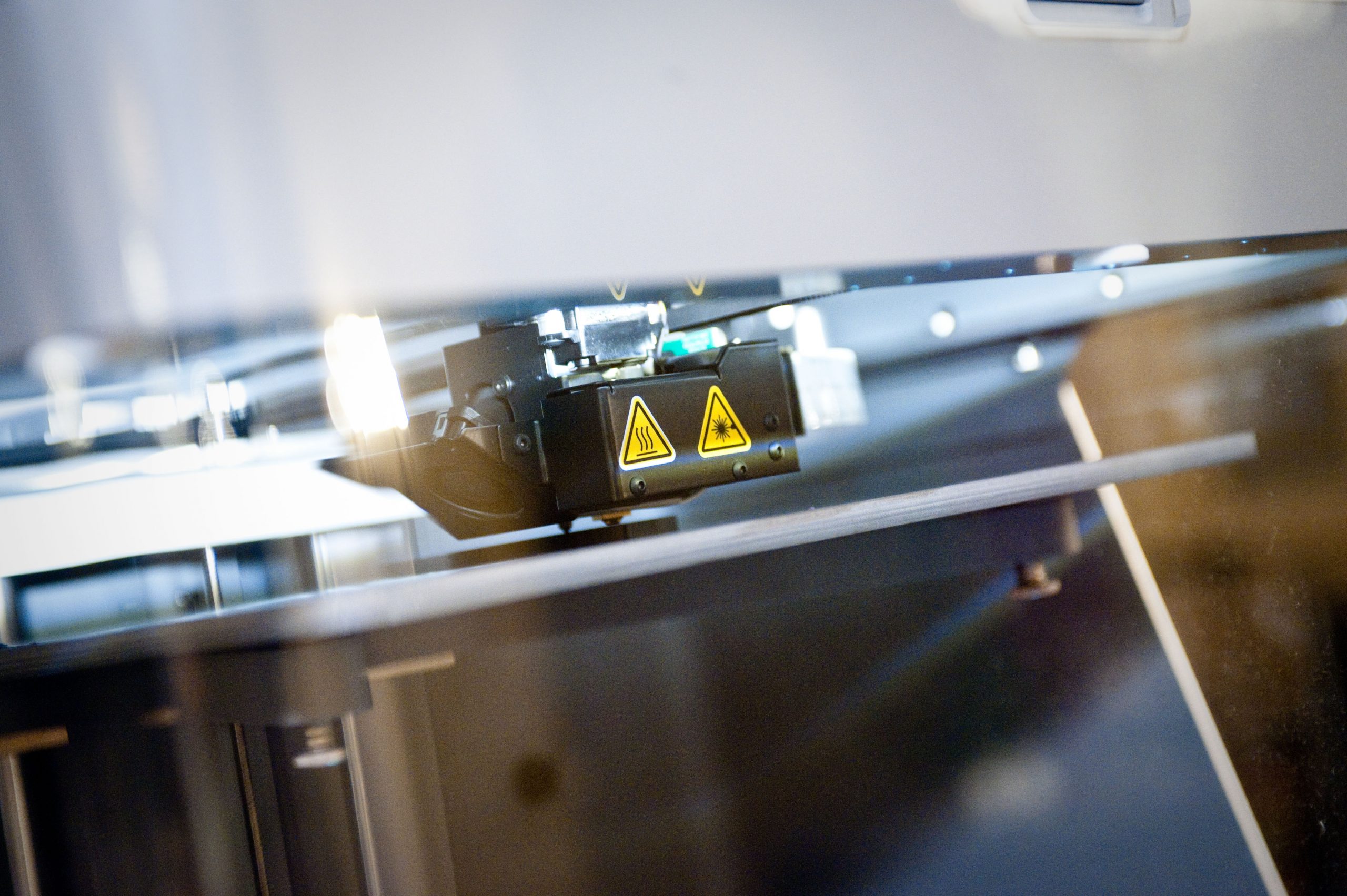

The Markforged X7 3D printer is the flagship on the market. Industrial-grade, 3D printed, incredibly strong parts combined with laser-assisted build process control make the Markforged X7 a must-have for every manufacturing company.

Large installation space

The large build volume of the Markforged X7 is ideal for tooling, gripper construction, robotics, automotive parts, and functional prototypes, and is almost three times larger than the build volume of the Markforged Mark Two. With a layer height of 50 μm, your 3D-printed parts will have a beautiful surface finish, similar in appearance and feel to an injection-molded part.

The 3D printers of the Markforged X-Series comparison

Touchscreen interface and webcam monitoring*

The Markforged X7 features a built-in touchscreen that lets you easily connect to Wi-Fi, start printing, and manage your printer.

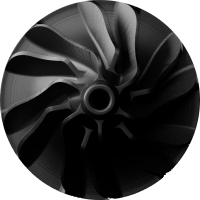

Why continuous fibers?

Carbon fiber is only optimally designed to withstand tensile and compressive forces if the force acting on the component is applied in the direction of the fiber grain. If the carbon fiber is interrupted during the construction process, it can no longer absorb the optimal tensile and compressive forces. This is why the continuous fiber is so crucial for the stability of a component printed with carbon fiber, Kevlar®, or glass fiber. Continuous fiber-reinforced 3D printing thus ensures strength at a completely new level.

The technology: CFF

Continuous Filament Fabrication

Fiber-reinforced components are made of two materials and are incredibly strong and versatile. Our unique manufacturing process allows you to print components that are much stiffer and stronger than typical 3D printed parts.

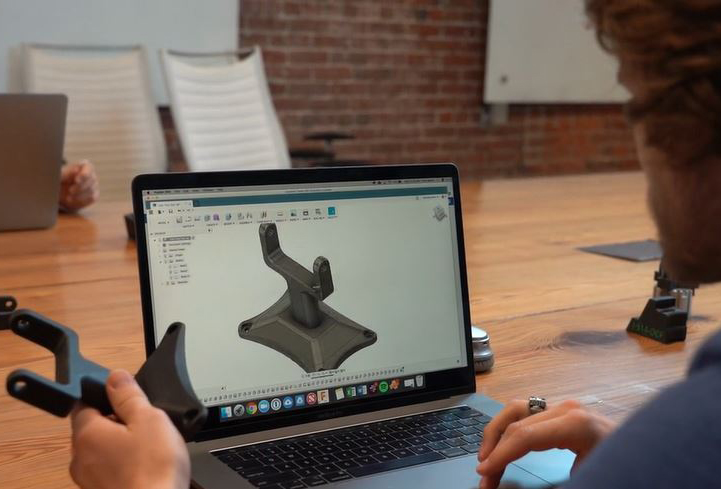

DESIGN

Create an STL file from your CAD model and load it into the EIGER software. Select the appropriate composite material, such as carbon, fiberglass, or Kevlar. The cloud-based software will do the rest, making it easy to print the right part.

STRENGTHEN

The dual material system produces the fiber-reinforced component layer by layer. The first nozzle forms the plastic matrix, and the second nozzle continuously deposits the composite fiber.

COMPONENT

Markforged CFF components are as strong as aircraft aluminum and over 40% lighter than machined metal tools, fixtures, and prototypes.

Internal reinforcement

CARBON FIBER

Continuous carbon fiber parts withstand the toughest applications.

Outer shell

ONYX

Engineered to combine the strength and durability of nylon with the dimensional stability and strength of composites, Onyx is the world's most powerful 3D printing plastic.

0.05 mm layer thickness

With a layer thickness of 0.05 mm, your components will have a perfect surface, similar in appearance and feel to an injection-molded component. Rz of 35 µm is possible!

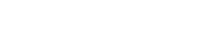

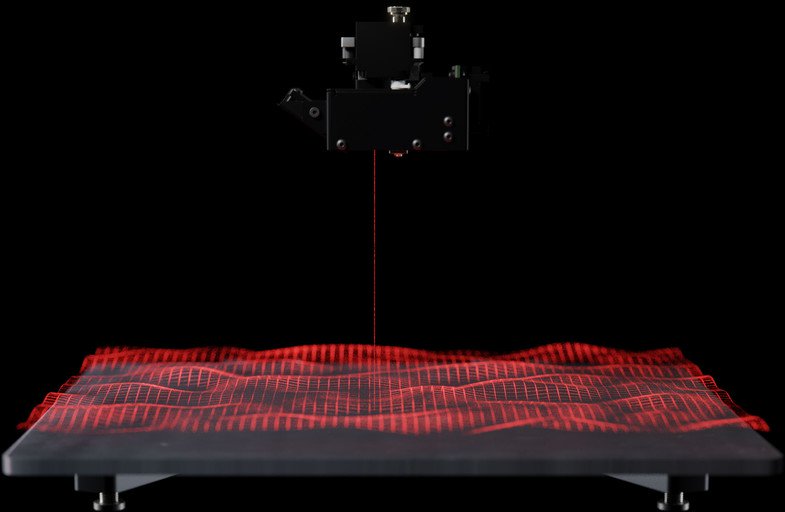

Laser-assisted construction process control

With the Markforged X7, you get quality and precision in 3D printing. Thanks to an integrated laser, you can scan the tolerances defined in the EIGER software during the printing process. The built-in camera allows you to continuously monitor the build process from anywhere in the world.

Print components with the known precision & tolerance

All Markforged 3D printers work closely with the EIGER software and are perfectly coordinated. Define your tolerance specifications in EIGER, the included cloud-based 3D printer software. The Markforged X7 scans your part throughout the entire printing process to ensure your requirements are consistently met. If an error is detected, you'll receive a notification and have the option to stop the print remotely to save time and material.

Print 2x faster with Turbo Print

With the new "Turbo Print" feature, the Markforged X7 can print twice as fast as before! Turbo Print is now compatible not only with all second-generation Markforged X7 3D printers, but also with the first generation!

Learn more about the applications of plastic 3D printing with continuous fibers!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Would you like a demo, have questions or need a quote for a Markforged X-Series printer?

Contact us now!

Rodenbacher Straße 15

35708 Haiger

Phone: 07361 63396 00

E-mail: markforged@mark3d.de

World-leading companies trust Markforged 3D printers