BODUK Co., Ltd.

The customer

BODUK's predecessor, when it was founded in 1997, was the first Japanese website focused on importing, developing, and selling drones and other remotely controlled devices to consumers. When President Houe Ohta anticipated a decline in the popularity of drones, he refocused the company on the growing industrial drone market. In 2002, he founded BODUK Co. Ltd. to focus on the design and development of unique products to enhance infrastructure inspections.

BODUK has reduced the manufacturing time of its drones by half to one-third – a significant improvement due to the exceptional yield and a reduction in labor costs.

The challenge

"Can they be used for inspecting large structures like buildings, bridges, and dams?" wondered Ohta, a civil engineering expert. At the time, drones were primarily used to collect and transmit video and temperature data. Ohta wanted to further develop drone technology so that it could be used for non-destructive inspections.

Thanks to funding from Saitama Prefecture for robotics startups, BODUK purchased a 3D printer in 2013. Over the next three years, Ohta and his team thoroughly tested the printer to understand "what it could do and how useful it could be."

Non-destructive inspection can capture internal data about structural integrity through methods such as external impacts against a concrete wall or the application of electromagnetic waves. A crucial component for such work is a proximity sensor. To be able to use it in a flying device such as a drone, the weight of the sensor and the mount that supports it had to be as low as possible.

"Depending on the type and size of the inspection equipment, the mount, which must accommodate 1 kg of equipment, weighs approximately 3 kg," explains Ohta. This sensor mount also had to be strong enough to withstand the harsh environmental conditions the drone may encounter during inspections.

Finally, the 3D printer for mass production of this bracket needed to have reproducible precision so that the parts could be reliably assembled during manufacturing. Some of the 3D printers Ohta and his team studied had difficulty achieving this level of precision.

The solution

BODUK invested in a Markforged Onyx One and a Mark Two in 2017. The company now owns 15 Markforged printers, including X7 industrial printers. By expanding its printer fleet, BODUK has been able to significantly increase production efficiency:

"With decentralized batch processing, it's more effective to increase the number of devices than to increase the speed of a unit. At the same time, we can mitigate risks. For example, adding three devices increases productivity fivefold, not threefold," explains Ohta.

Markforged's products have proven capable of meeting BODUK's sometimes conflicting requirements. The combination of strength and elasticity is evident, for example, in BODUK's 3D-printed propeller guards. Carbon fiber is the perfect material for this application, as it offers an optimal balance between toughness and elasticity, allowing it to protect the propeller without compromising its function.

The reproducible precision of Markforged printers is evident in the seamless connections between the parts of the BODUK drones, which use 50 mm thick carbon rods to align and connect 13 parts. “Markforged 3D printers achieve a precision of 0.02 mm”, says Ohta.

Overall, he is very satisfied with the performance and precision of his Markforged printers:

"The good results reduce labor costs and allow employees to work without stress. We are also satisfied with the high, reproducible precision provided by the linear guide. In short, the printers are extremely cost-effective."

According to his estimates, Markforged printers have reduced production time by half to one-third compared to competitor products. “Reducing downtime reduces hidden costs and gives us more time for better product development.”, Ohta continued.

The future

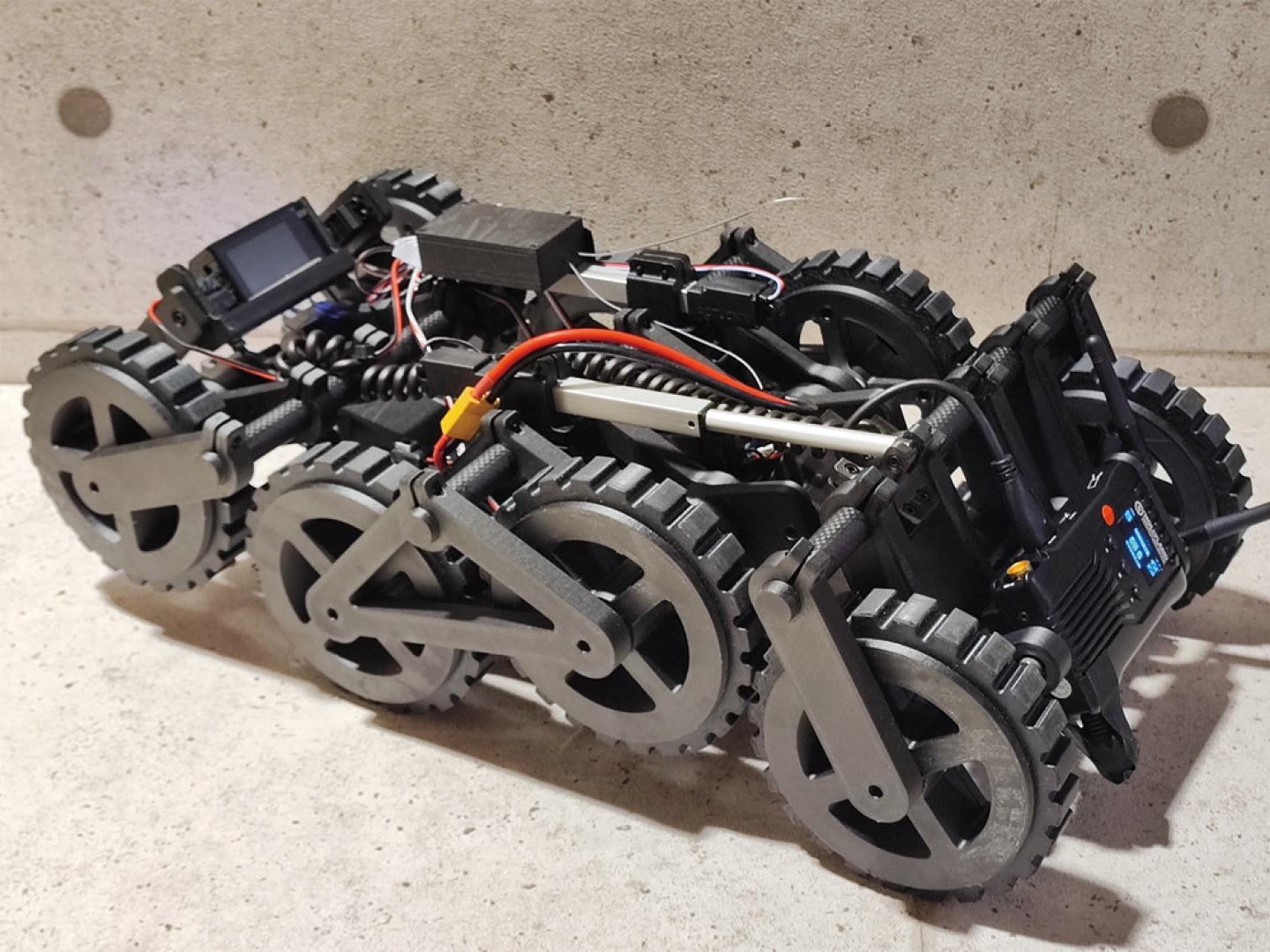

BODUK's expertise in developing aircraft such as airplanes and helicopters is being applied to the development of unique industrial drones, including climbing robots. The company's next growth phase will be the development and commercialization of mobile robots for underbody inspections. This is part of its efforts to deploy drones and robots in confined spaces that are difficult for human inspectors to access.

"I'm convinced that the potential applications in civil and structural engineering are far from exhausted. One possible application, for example, would be an inspection device used in a highway maintenance depot. It would primarily serve to support the manual work of the workers," Ohta says.

Ohta's ideas, like his drones soaring through the sky, offer limitless possibilities. With Markforged printers, he has every reason to believe he can turn many of them into innovations that benefit the sectors his company serves.

"It's important that good results reduce labor costs and allow employees to work without stress. We are also satisfied with the high, reproducible precision provided by the linear guide. In summary, the entire process was extremely cost-effective."

– HOUE OHTA DIRECTOR OF THE COMPANY

Learn more about the applications with the MarkTwo!

Which continuous filament is suitable for which application? How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed several information sources that will help you get the answers you need.

Construction guide

This guide is intended to help you generate ideas for better design results for your components. It's specifically designed for additive manufacturing processes.

Stronger than aluminum

For years, a compromise between strength, delivery time, and cost had to be accepted. This can now be easily avoided!

User report

In this practical application report from Kessler Plastics, (functional) prototypes are printed quickly and easily using the MarkTwo.

Hinterlasse einen Kommentar