Markforged announces Metal X Gen 2, Next Day Metal and the X7 Field Edition

New printers and software updates for The Digital Forge enable manufacturers to overcome challenges faster and easier than before

Watertown, Massachusetts – June 22, 2021 – Markforged, developer of the integrated metal and carbon fiber additive manufacturing platform, the Digital Forge, today announced three major platform enhancements: Metal X Gen 2, Next Day Metal, and X7 Field Edition. Together, these new hardware and software releases are designed to help manufacturers transform how they respond to global supply chain challenges and produce parts efficiently and safely at the point of need. Whether on a factory floor or in the most remote areas of the world, these advancements are designed to enable manufacturers to recover faster from broken parts, operate with less inventory, and minimize equipment downtime.

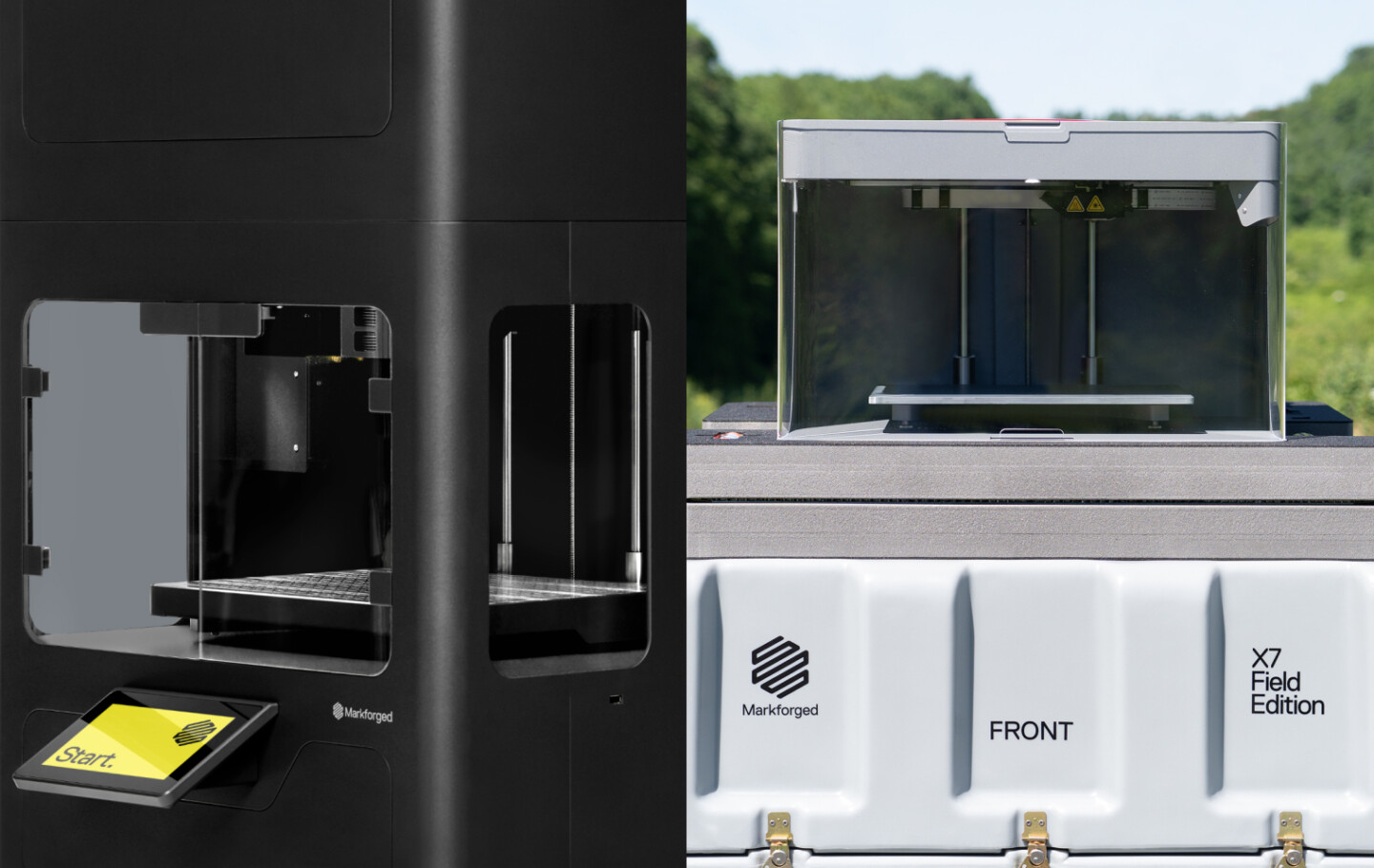

The Metal X Gen 2 builds on the success of its predecessor, the original Metal X System released in 2017, by pushing the boundaries of what's possible in printing complex, industrial-grade metal parts with key hardware developments that enhance the user experience and increase operator safety to make metal printing even easier. New features—an external 7-inch touchscreen, door position sensors, and additional chamber insulation—make the Gen 2 even more energy- and time-efficient than before.

Simultaneously with the launch of the Metal X Gen 2, Markforged will release Next Day Metal for its entire global fleet of metal printers. Over-the-air software update enables up to twice the print speeds of before to produce high-quality, strong metal parts. Wash and dry times—a crucial step in the metal 3D printing process—are now more precise for smaller parts, reducing the required debinding cycle time. These factors, combined with an approximately 17-hour small-part express run on the Sinter-2 post-processing furnace, allow manufacturers to deliver the parts they need faster and—thanks to increased capacity on each printer—enable them to scale their additive manufacturing.

The Markforged Metal X Gen 2 is here!

Additive manufacturing of metals redefined.

✅ Print speed up to 2x faster

✅ Part-in-hand time significantly reduced

✅ Design improvements

Experience the Markforged Metal X Gen 2 including the Sinter 2 and washing station at our technology center in Haiger!

👉 Make an appointment now: https://lnkd.in/dJAbJYU

Request a DEMO component now!

See for yourself how strong the components are.

Next Day Metal's increased production speed will be critical for manufacturers like Markforged customer Angus 3D Solutions, a Scotland-based print service provider. The Angus 3D Solutions team needed to manufacture some specialized wrenches for their customer, and traditional processes would have taken too long and required the part to be air-freighted to its destination to meet the end customer's deadline. By leveraging the Markforged Metal X system, Angus 3D Solutions completed a prototype in three days instead of two to three weeks and was able to fulfill the entire order on time, saving approximately $25,000 in shipping costs and avoiding unplanned downtime for the end user's operation. With Next Day Metal, the same part could be produced overnight.

"Since we first used the Metal X, it has been a critical part of our business," said Andy Simpson, Managing Director of Angus 3D Solutions. The Scotland-based print service provider uses the Digital Forge platform to produce critical parts for its customers—including some of Scotland's largest oil and gas companies. "Our customers rely on us to manufacture specialized parts that can be time-consuming to manufacture and expensive to ship quickly. Our Markforged Metal X printer allows us to fulfill orders quickly and on time. Next Day Metal opens up new potential for us to scale our metal printing business and meet customer needs with even faster turnaround times."

The supply chain and manufacturing challenges that rely on The Digital Forge aren't limited to the factory floor. The X7 Field Edition (X7 FE) enables the deployment of Markforged technology in the most demanding environments in every corner of the world, helping engineers, operators, and service personnel reinvent the way they address global supply chain challenges.

The X7 FE is a rugged, field-deployable industrial 3D printer for tactical response to inventory challenges in remote locations, as used by the U.S. Marine Corps' XFAB program. The X7 FE is equipped with a roto-molded, high-impact polyethylene Pelican case to protect it during transport through harsh environments. The case contains all the tools, spare parts, and materials needed for field maintenance and repair. Customers can drop the device directly into harsh environments such as combat zones and exploration sites and print in less than two minutes.

"Manufacturers face many challenges in today's marketplace—from supply chain challenges like rising delivery costs and shipping delays to increased market pressure to innovate faster and stay ahead of the competition," said Shai Terem, President and CEO of Markforged. "Since Markforged shipped our first printer, we've been committed to quality and continuous improvement, always seeking simpler, smarter, and more robust ways to empower our customers to build anything they can imagine. The addition of Metal X (Gen 2), Next Day Metal, and X7 FE to our Digital Forge are important steps toward reinventing manufacturing today so we can be more resilient tomorrow, anywhere in the world."

The Metal X Gen 2 and Next Day Metal for both the Metal X Gen 1 and Gen 2 are available starting today. The X7 FE is available for pre-order starting today and will ship starting in fall 2021.

About Markforged

Markforged transforms manufacturing with 3D metal and continuous carbon fiber printers capable of producing parts tough enough for the factory floor. The Markforged Digital Forge brings the power and speed of agile software development to industrial manufacturing, combining hardware, software, and materials to eliminate the barriers between design and functional parts. Engineers, designers, and manufacturing professionals all over the world rely on Markforged metal and composite printers for tooling, fixtures, functional prototyping, and high-value end-use production. Founded in 2013 and based in Watertown, Mass., Markforged has more than 250 employees globally. Markforged has been recognized by Forbes in the Next Billion-Dollar Startups list, and was listed as the #2 fastest-growing hardware company in the US in the 2019 Deloitte Fast 500. In February 2021, Markforged announced it entered into a definitive agreement to merge with one (NYSE: AONE), a special purpose acquisition company founded and led by technology industry veteran Kevin Hartz. The transaction is expected to close in the summer of 2021, subject to regulatory and stockholder approvals, and other customary closing conditions. The combined company will retain the Markforged name and be listed on the NYSE under the ticker symbol “MKFG”.

About one

one is a special purpose acquisition company sponsored by A* formed for the purpose of effecting a business combination with one or more businesses in the innovation economy. one completed its initial public offering in August 2020 raising $215 million in cash proceeds. A* was founded and is led by technology industry veteran Kevin Hartz.

Participants in the Solicitation

one and Markforged and their respective directors and executive officers may be considered participants in the solicitation of proxies with respect to the potential transaction described in this document under the rules of the Securities Exchange Commission (the “SEC”). Information about the directors and executive officers of one and Markforged are set forth in one's Proxy Statement and Prospectus filed pursuant to Rule 424B(3) with the SEC on June 24, 2021 (the “Registration Statement”), and other filings with the SEC that are available free of charge at the SEC's website at www.sec.gov or by directing a request to: one, 16 Funston Avenue, Suite A, The Presidio of San Francisco, San Francisco, California 94129, Attention: Secretary. Information regarding the persons who may, under the rules of the SEC, be deemed participants in the solicitation of the one Shareholders in connection with the potential transaction are set forth in the Registration Statement filed with the SEC. These documents can be obtained free of charge from the sources indicated above.

Non-Solicitation

This press release is not a proxy statement or solicitation of a proxy, consent or authorization with respect to any securities or in respect of the potential transaction and shall not constitute an offer to sell or a solicitation of an offer to buy the securities of one, the combined company or Markforged, nor shall there be any sale of any such securities in any state or jurisdiction in which such offer, solicitation, or sale would be unlawful prior to registration or qualification under the securities laws of such state or jurisdiction. No offer of securities shall be made except by means of a prospectus meeting the requirements of the Securities Act of 1933, as amended.

Special Note Regarding Forward-Looking Statements

This press release contains forward-looking statements that are based on beliefs and assumptions and on information currently available. In some cases, you can identify forward-looking statements by the following words: “may,” “will,” “could,” “would,” “should,” “expect,” “intend,” “plan,” “anticipate,” “believe,” “estimate,” “predict,” “project,” “potential,” “continue,” “ongoing” or the negative of these terms or other comparable terminology, although not all forward-looking statements contain these words. These statements involve risks, uncertainties and other factors that may cause actual results, levels of activity, performance or achievements to be materially different from the information expressed or implied by these forward-looking statements. Although Markforged believes that it has a reasonable basis for each forward-looking statement contained in this press release, Markforged cautions you that these statements are based on a combination of facts and factors currently known by it and its projections of the future, about which it cannot be certain. Forward-looking statements in this press release include, but are not limited to, statements regarding the proposed business combination, including the timing and structure of the transaction, the functionality and applications of Markforged's products, the expected benefit to customers of upgrades to Markforged's printers, expected shipping dates for products, the impact of Markforged's products on its financial conditions and results of operation, and the integration of Markforged's products into the additive manufacturing market. Markforged cannot assure you that the forward-looking statements in this press release will prove to be accurate. These forward looking statements are subject to a number of risks and uncertainties, including, among others, general economic, political and business conditions; the inability of the parties to consume the business combination or the occurrence of any event, change or other circumstances that could give rise to the termination of the business combination agreement; the effect of COVID-19 on Markforged's business and financial results; the outcome of any legal proceedings that may be instituted against the parties following the announcement of the business combination; the risk that the approval of the shareholders of one for the potential transaction is not obtained; failure to realize the anticipated benefits of the business combination, including as a result of a delay in consuming the potential transaction; the risk that the business combination disrupts current plans and operations as a result of the announcement and consumption of the business combination; the ability of the combined company to grow and manage growth profitably and retain its key employees; the amount of redemption requests made by one's shareholders; the inability to obtain or maintain the listing of the combined company's securities following the business combination; costs related to the business combination; and those factors discussed under the header “Risk Factors” in the Registration Statement and those included under the header “Risk Factors” in one's Annual Report on Form 10-K and other filings with the SEC. Furthermore, if the forward-looking statements prove to be inaccurate, the inaccuracy may be material. In light of the significant uncertainties in these forward-looking statements, you should not regard these statements as a representation or warranty by us or any other person that Markforged will achieve its objectives and plans in any specified time frame, or at all. The forward-looking statements in this press release represent Markforged's views as of the date of this press release. Markforged anticipates that subsequent events and developments will cause its views to change. However, while Markforged may elect to update these forward-looking statements at some point in the future, Markforged has no current intention of doing so except to the extent required by applicable law. You should, therefore, not rely on these forward-looking statements as representing Markforged's views as of any date subsequent to the date of this press release.

Contacts

Investors

investors@markforged.com

Media

Paulina Bucko

Head of Communications

paulina.bucko@markforged.com

Learn more about the applications with the desktop series!

How do I design correctly for filament 3D printing? What do users say about it, and where can I find more information? – You've come to the right place! We've listed some information sources that will help you get the answers you need.

Hinterlasse einen Kommentar